An energy-saving and environmentally friendly melting and casting furnace

An energy-saving and environment-friendly casting furnace technology, applied in furnaces, crucible furnaces, furnace components, etc., can solve the problems of insufficient combustion, environmental pollution, and limited temperature rise, and achieve the effects of long furnace start-up time, extensive trial use, and reduced exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

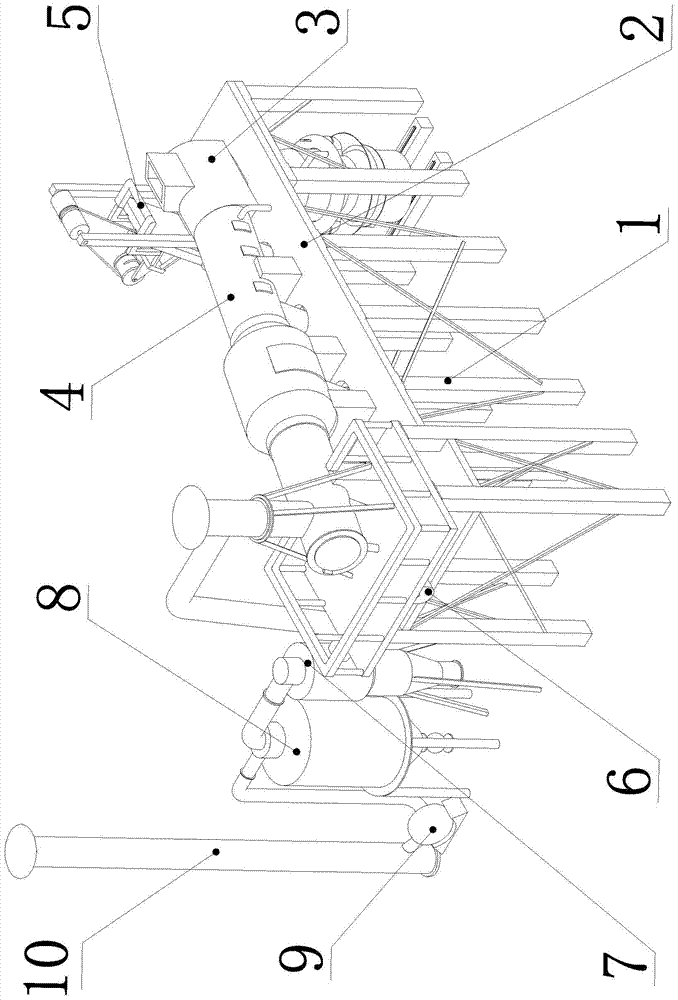

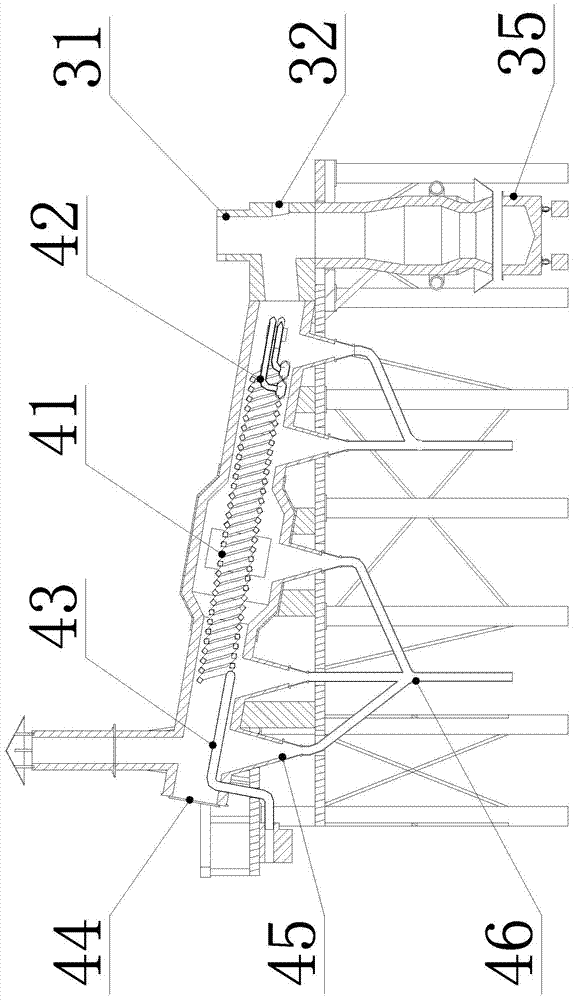

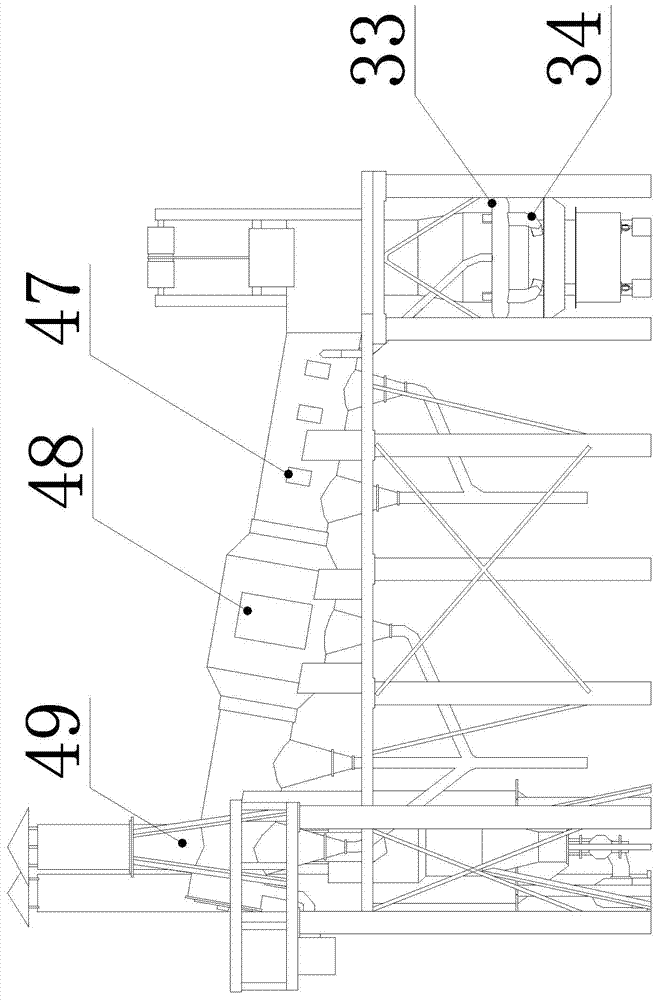

[0020] refer to figure 1 , figure 2 and image 3 , an energy-saving and environmentally friendly melting and casting furnace, including a furnace body made of multi-layer insulation materials, a supporting steel frame for installing and supporting the furnace body, and dust removal and purification equipment. The supporting steel frame includes a supporting column 1 and a supporting platform 2; the furnace body includes a first combustion chamber 3 vertically installed in the supporting steel frame and a second combustion chamber 4 installed obliquely on the supporting steel frame; the second combustion chamber The input end of the chamber 4 communicates with the upper part of the first combustion chamber 3; the top of the first combustion chamber 3 is provided with a feed port 31; the upper side wall of the first combustion chamber 3 is provided with There is an air inlet 32; the bottom of the first combustion chamber 3 is provided with an annular duct 33; the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com