Reflective film with moth-eye structure and its preparation process

A reflective film and moth-eye technology, which is applied in the field of optics, can solve the problems of low reflective rate of reflective film, achieve simple manufacturing process, good reflective effect, and reduce the loss of incident light on the incident surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

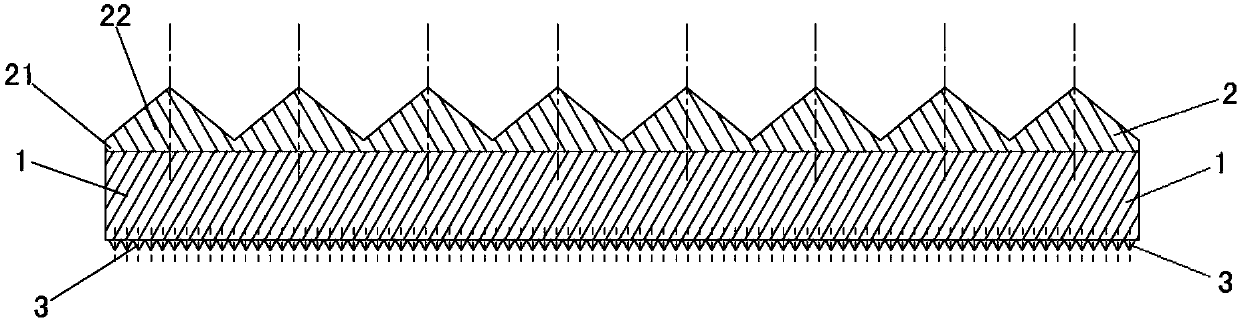

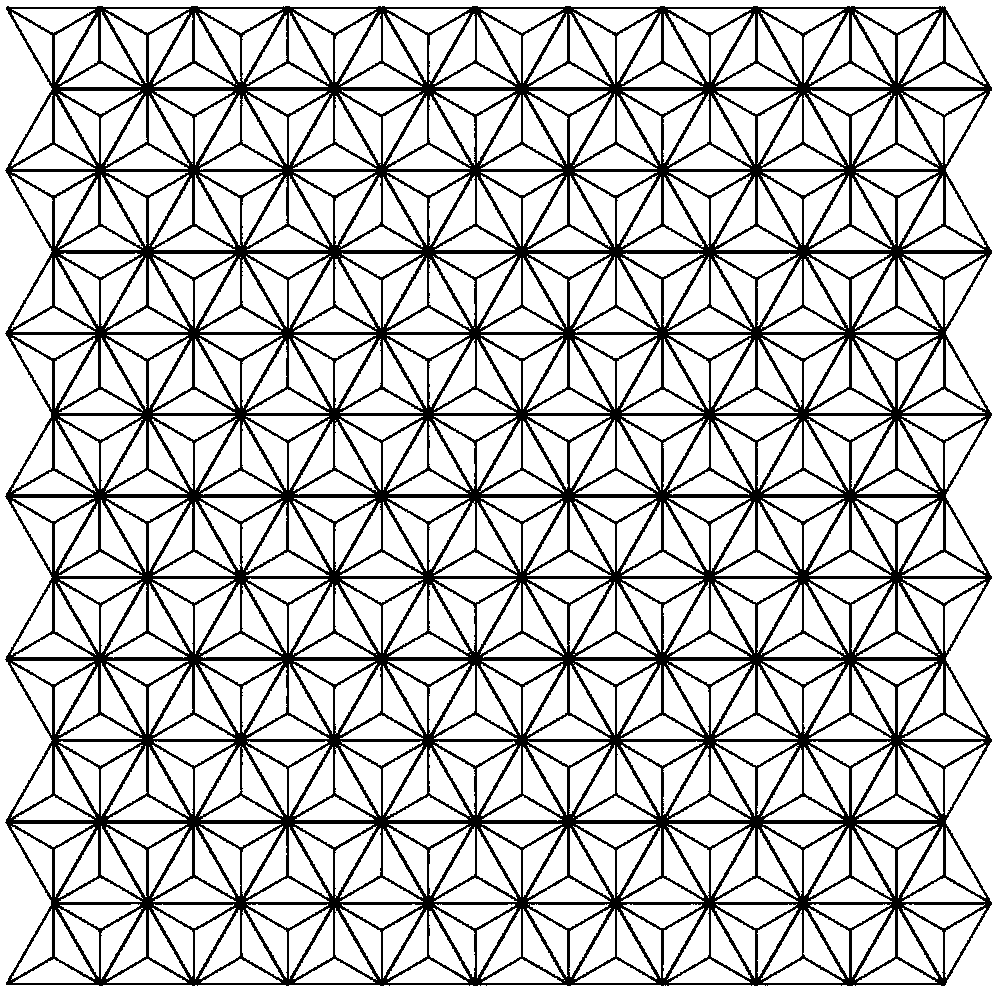

[0031] see figure 1 , with reference to figure 2 , image 3 , the reflective film with a moth-eye structure of the present invention includes a PET layer 1, a reflective structure layer 2 and a moth-eye anti-reflection structure layer 3, the light-reflection structure layer 2 is arranged on one side surface of the PET layer 1, and the moth-eye anti-reflection structure layer 3 is arranged on the other side surface of PET layer 1.

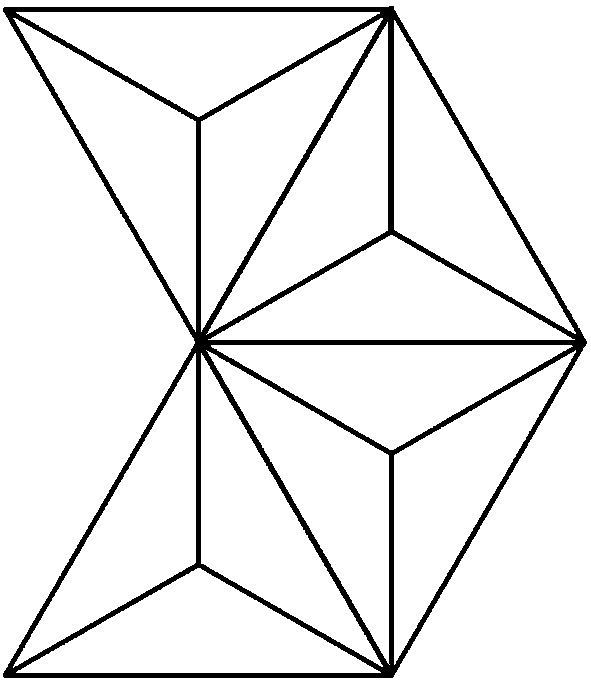

[0032] The reflective structure layer 2 in the present invention includes a resin bottom layer 21 and a UV light-curable resin layer 22, the resin bottom layer is attached to the PET layer, and the UV light-curable resin layer is attached to the resin bottom layer.

[0033] The UV photocurable resin layer in the present invention is a pyramid-shaped triangular pyramid structure, three sides are perpendicular to each other, and the length of the bottom side is 10mm-175mm. The smaller the value of the base length within the allowable range, the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com