Method for manufacturing printed circuit board and printed circuit board

A technology of printed circuit board and manufacturing method, which is applied in the direction of printed circuit manufacturing, printed circuit, and the formation of electrical connection of printed components, etc., which can solve the problem of insufficient adhesion between a conductive paste layer and a substrate, increased interface separation or detachment, failure to Solve problems such as practical use, and achieve the effects of preventing leakage, shortening the process, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

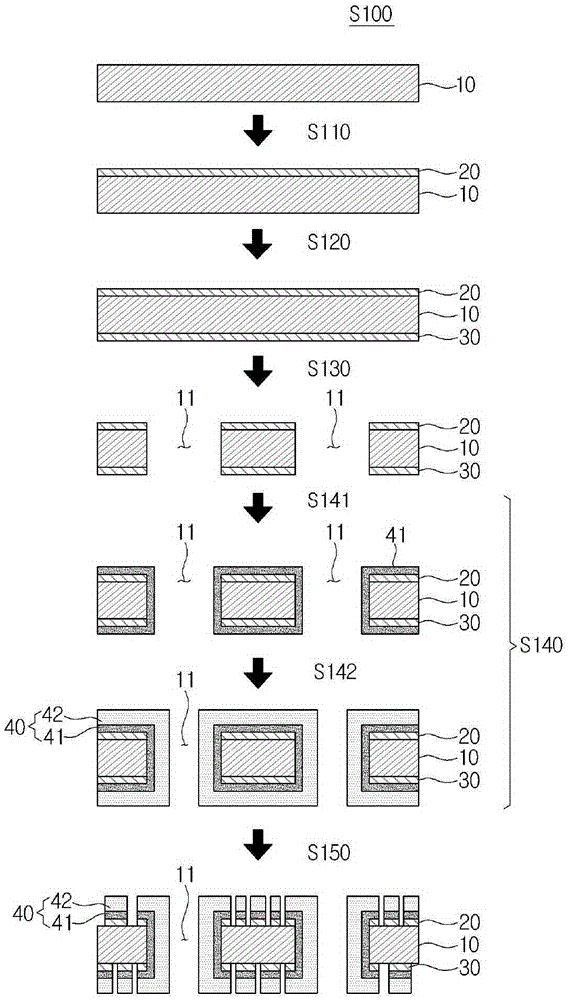

[0063] figure 1 It is a figure which schematically shows the process flow of the manufacturing method of the printed circuit board of 1st Example of this invention.

[0064] like figure 1 As shown, the manufacturing method S100 of the printed circuit board according to the first embodiment of the present invention includes the forming step S110 of the first coating, the forming step S120 of the second coating, the perforating step S130, the plating step S140 and the formation of the circuit pattern Step S150.

[0065] The step S110 of forming the first coating layer and the step S120 of forming the second coating layer are the steps of coating the first coating layer 20 and the second coating layer 30 on the upper surface and the lower surface of the substrate 10 respectively. In addition, although a polyimide film (PI: PolyImideFilm) was used as the substrate 10 in this step, it is not limited thereto.

[0066] The conductive ink is coated on the prepared upper surface of ...

no. 2 example

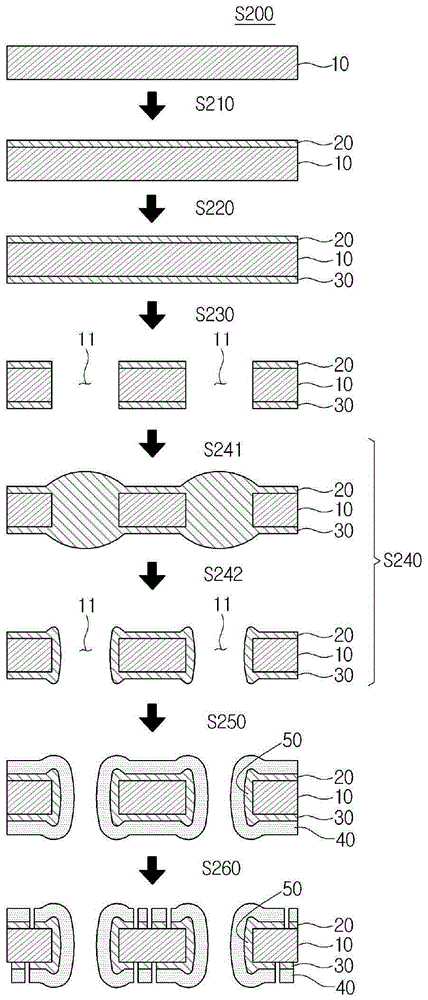

[0080] figure 2 It is a figure which schematically shows the process flow of the manufacturing method of the printed wiring board which concerns on the 2nd Embodiment of this invention.

[0081] like figure 2 As shown, the manufacturing method S200 of the printed circuit board according to the second embodiment of the present invention includes the forming step S210 of the first coating layer, the forming step S220 of the second coating layer, the perforating step S230, the forming step S240 of the conductive layer, and the plating step. Step S250 and step S260 of forming a circuit pattern.

[0082] The step S210 of forming the first coating and the step S220 of forming the second coating are the steps of coating the first coating 20 and the second coating 30 on the upper surface and the lower surface of the substrate 10 respectively. In addition, a polyimide film (PI: PolyImideFilm) may be used as the substrate 10 in this step, but is not limited thereto.

[0083] The co...

no. 3 example

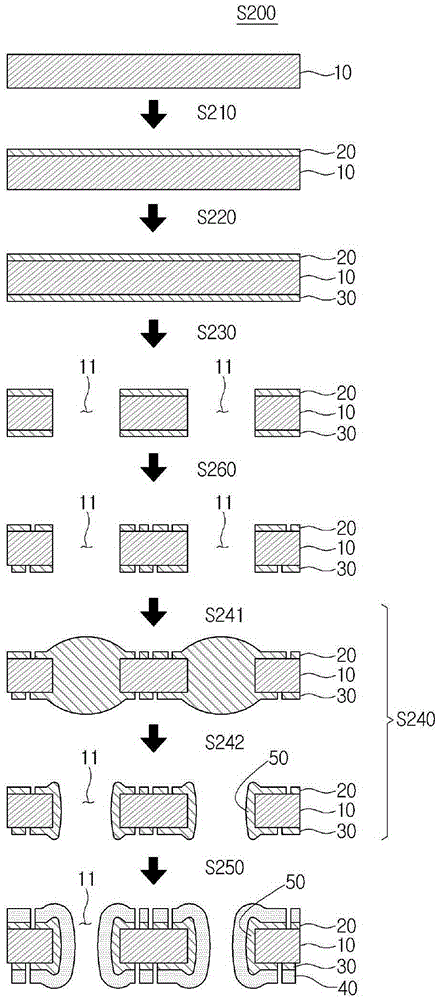

[0100] Figure 4 It is a figure which schematically shows the process flow of the manufacturing method of the printed circuit board of the 3rd Embodiment of this invention.

[0101] like Figure 4 As shown, the manufacturing method S300 of the printed circuit board according to the third embodiment of the present invention includes the forming step S310 of the first coating layer, the forming step S320 of the second coating layer, the perforating step S330, the bonding step S340 of the temporary sealing layer, The forming step S350 of the conductive layer, the removing step S360 of the temporary plugging layer, the plating step S370 and the forming step S380 of the circuit pattern.

[0102] The step S310 of forming the first coating and the step S320 of forming the second coating are the steps of coating the first coating 20 and the second coating 30 on the upper surface and the lower surface of the substrate 10 respectively. In addition, a polyimide film (PI: PolyImideFilm)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com