Individual customized bone-cutting shape-righting guide plate and fabrication method thereof

An osteotomy and guide plate technology, applied in the field of computer-aided modeling, can solve the problems of too simple structure, failure of osteotomy, and few problems to be considered, and achieves the effect of facilitating quality analysis and comparison, improving construction accuracy, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific embodiments of the present invention are described in detail below.

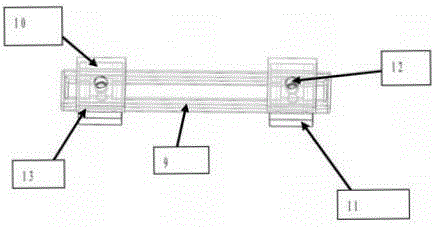

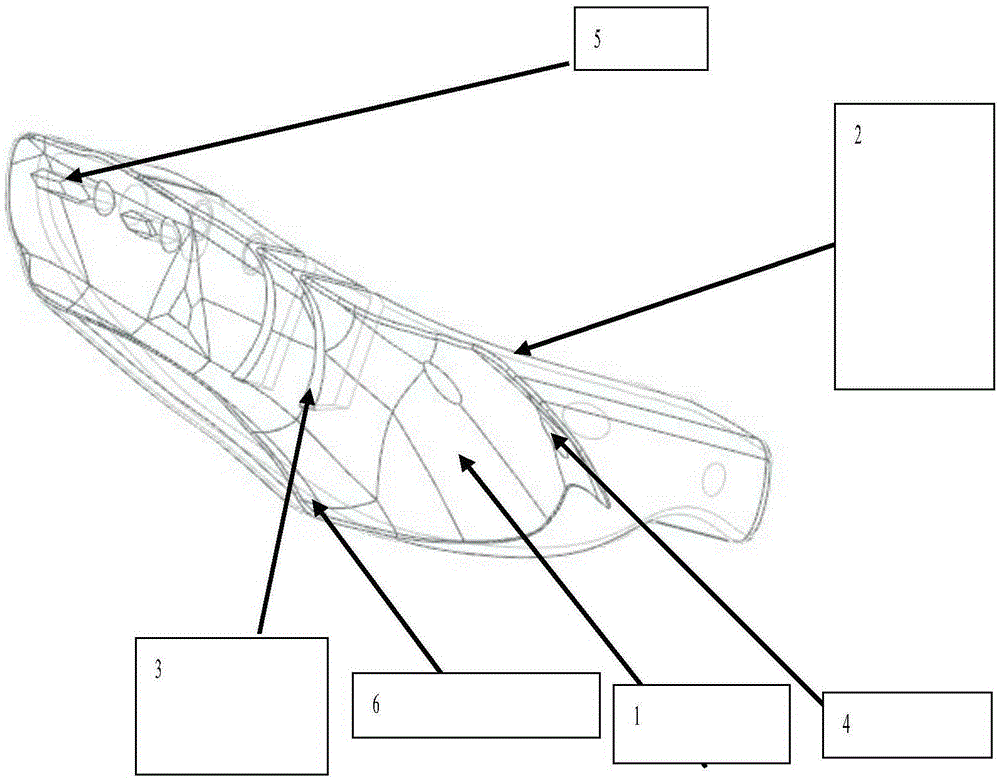

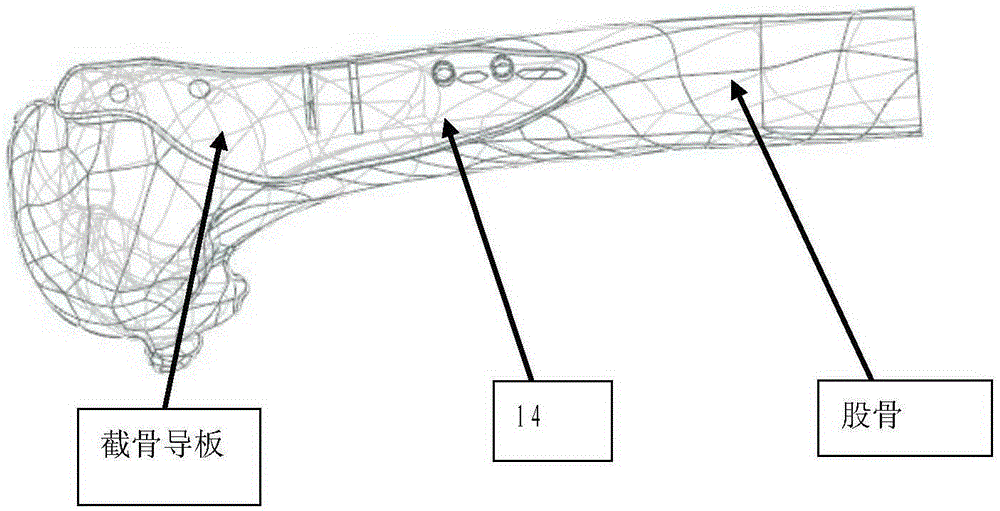

[0018] like Figure 1-5 As shown in the figure, the present invention customizes the osteotomy orthopedic guide plate, and its bone contacting working surface 1 is fitted with the bone surface, or a part of the bone that contacts with it can be embedded in the guide plate ( image 3 ), its outer surface 14 is determined by the thickness required for each position of the contact surface with the target bone, each side surface 3 of the guide plate is controlled by the arc of the bony prominence mark, and each side is aligned with the bony prominence mark to prevent the osteotomy guide from being placed The position is wrong; the middle part of the guide plate is provided with a number of osteotomy grooves 2, the osteotomy groove 2 can be used for the oscillating saw or the wire saw to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com