Stamping and molding process of automobile roof covers and stamping die

A technology for automobile top cover and stamping forming, applied in forming tools, manufacturing tools, vehicle parts, etc., can solve the problems affecting the final accuracy of parts, inaccurate positioning, poor stability and production consistency, and achieve good rigidity and strength. The flow and deformation are too intense, and the effect of improving the effect of turning hole forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

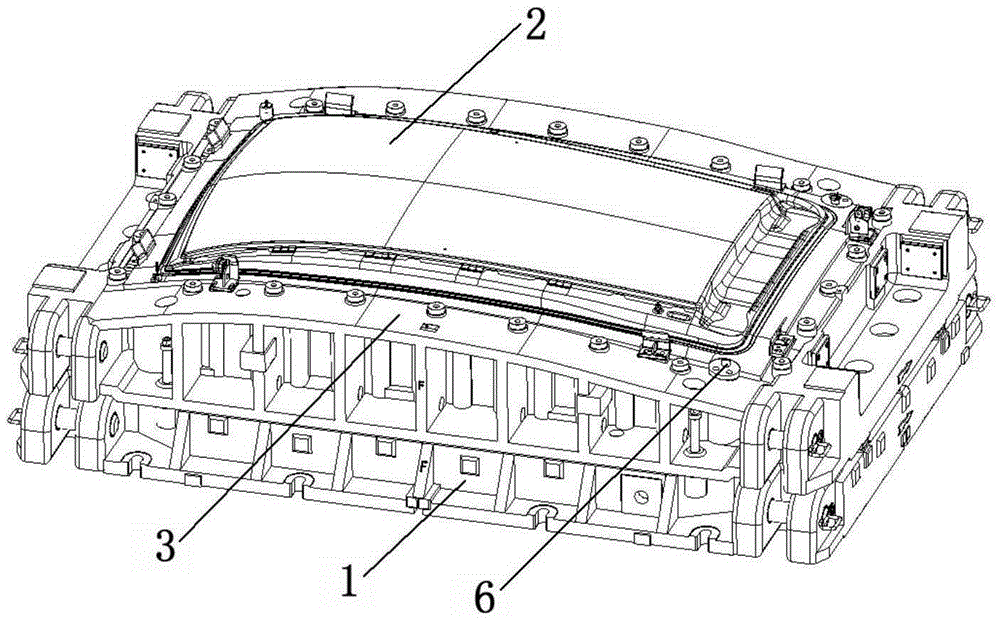

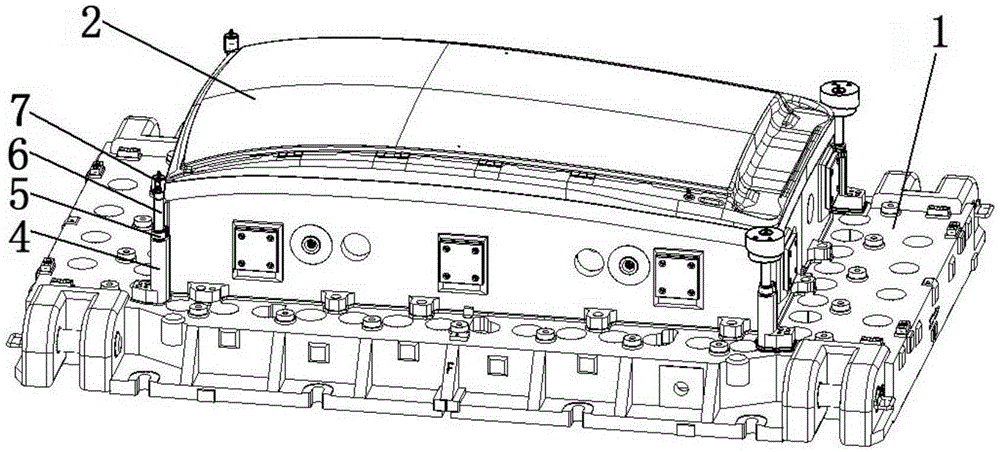

[0037] refer to figure 1 , The stamping die of this embodiment includes an upper mold base, a lower mold base 1 and a blank holder 3. For clarity, the upper mold base is omitted in the figure. A punch 2 and a hole-turning punch 6 are installed on the lower mold base 1 . The punch 2 is used to form the main shape of the workpiece, and the hole turning punch 6 is used to realize turning the hole.

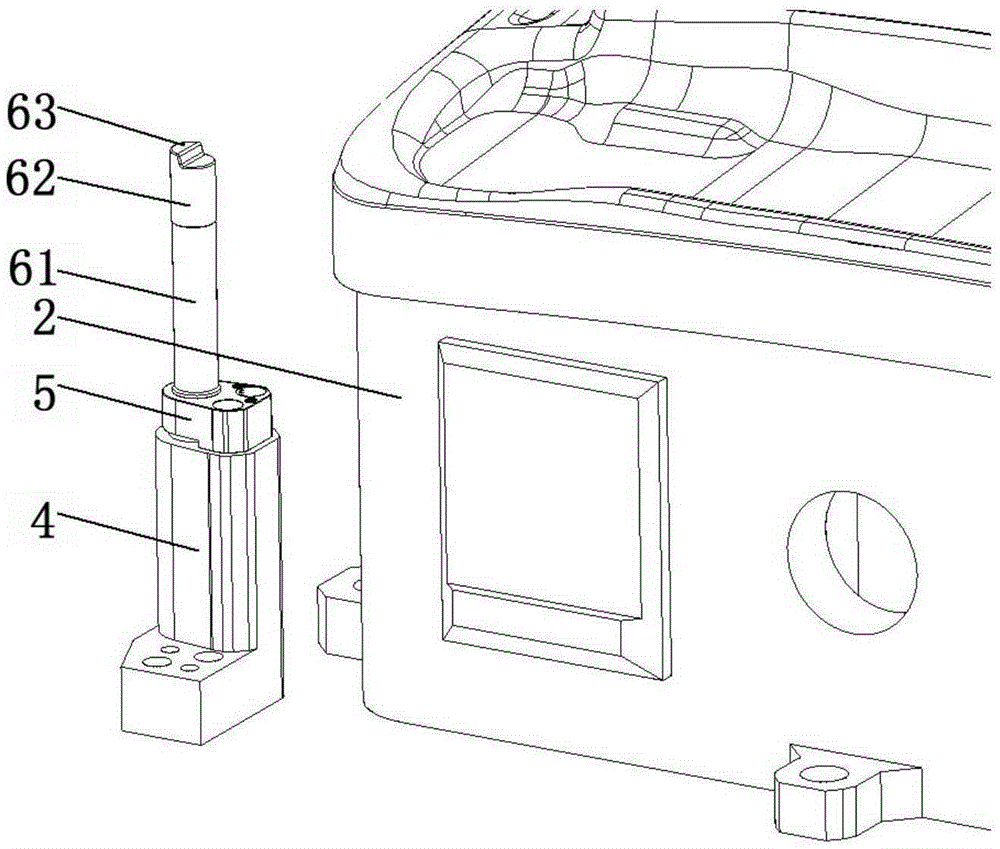

[0038] refer to figure 2 , image 3 , the installation base 4 is fixedly installed on the lower mold base 1, and the turning hole punch 6 is fixed on the installation base 4 through the fixing seat 5. The hole turning punch 6 has a mounting portion 61 and a hole turning portion 62 , wherein the mounting portion 61 is used to cooperate with the fixing seat 5 to realize installation, and the hole turning portion 62 is used to realize hole turning. At the top of the hole-turning punch 6, the end of the hole-turning portion 62 is a 1 / 3-circle boss 63, and other parts of the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com