Clamping and positioning device for flange

A technology for clamping and positioning and flanges, applied in positioning devices, clamping devices, clamping, etc., can solve problems such as increased processing procedures, prolonging processing time, and damage to flange structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

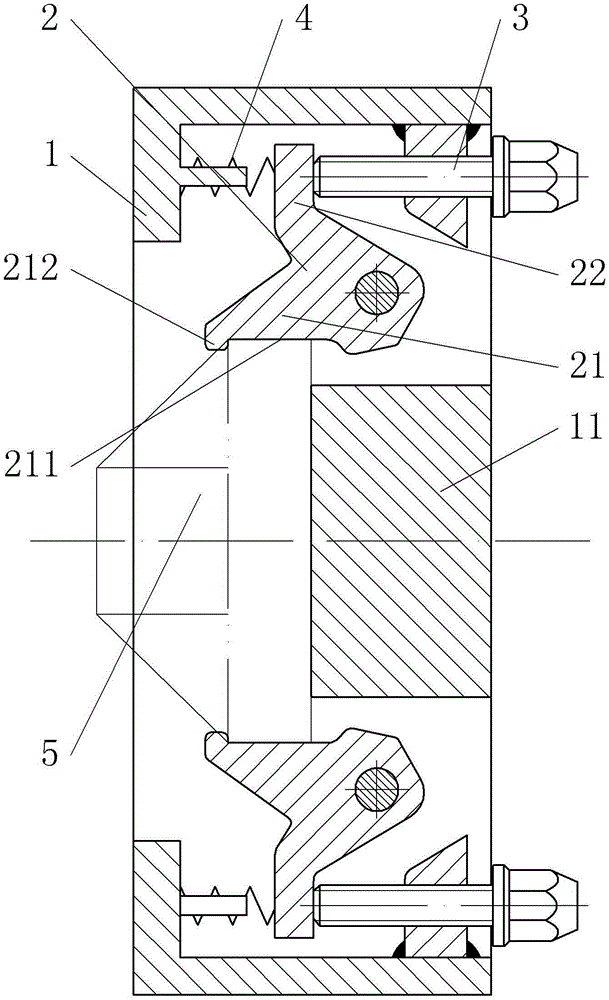

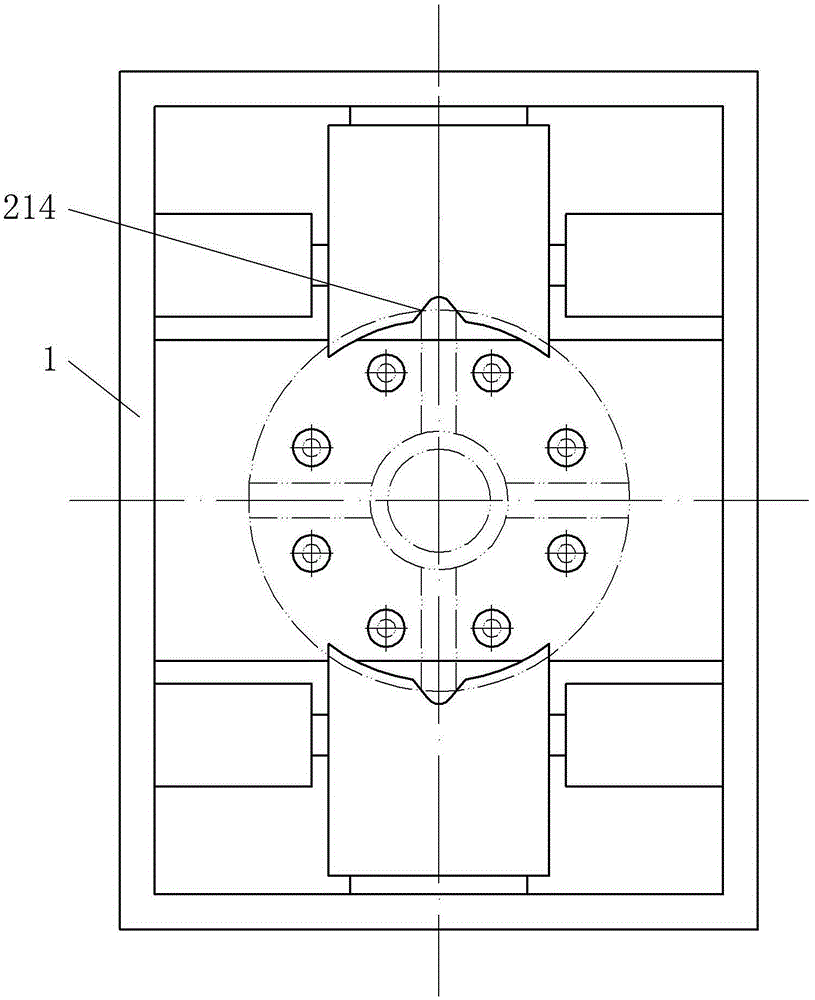

[0017] The embodiment is basically as attached figure 1 , figure 2 Shown: A clamping and positioning device for a flange includes a clamping seat 1, a clamping jaw 2, a compression bolt 3 and a return spring 4; the clamping base 1 is a square shell, and there are two clamping jaws 2 , and are symmetrically hinged in the inner cavity of the clamping seat 1, one end of the jaw 2 is the clamping end 21, and the other end is the force end 22, the clamping end 21 has a circular arc-shaped clamping surface 211, and the clamping The surface 211 has the same radian as the periphery of the flange 5 to be clamped, the clamping surface 211 is perpendicular to the force end 22, and there is an arc-shaped protrusion 212 on the left side of the clamping surface 211. There is a limit notch 214 on the protrusion 212, and the two opposite sides of the limit notch 214 have a certain slope; the compression bolt 3 is screwed on the clamping seat 1, located on the right side of the jaw 2, and ex...

Embodiment 2

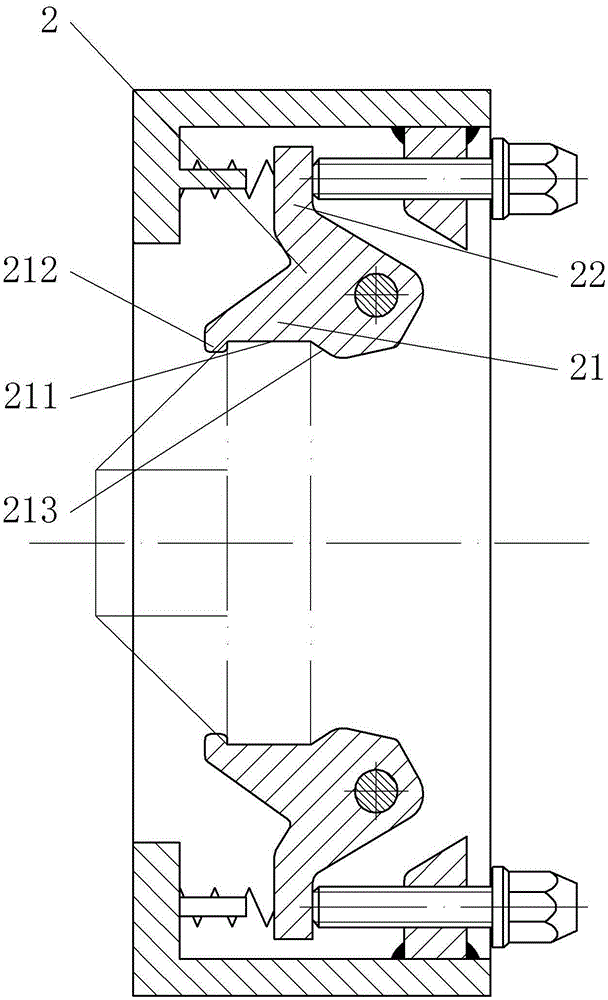

[0020] as attached image 3 As shown, the difference between the second embodiment and the first embodiment is that the limit block 11 is canceled in the second embodiment, and the limit arc surface 213 is set on the right side of the clamping surface 211 of the jaw 2, and the limit arc The surface 213 is an arc surface with the same radian as the clamping surface 211, the limiting arc surface 213 forms an included angle of 150o with the clamping surface 211, and the limiting arc surface 213 protrudes outward relative to the clamping surface 211, limiting The distance from the intersection line between the arc-shaped surface 213 and the clamping surface 211 to the intersection line between the arc-shaped protrusion 212 and the clamping surface 211 is equal to the thickness of the flange 5 .

[0021] During the clamping process, the two limit arc surfaces 213 also rotate toward the center at the same time, but due to the inclination between the limit arc surfaces 213 and the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com