Permanent magnet chain wall climbing robot with air rods for buffering

A technology of a wall-climbing robot and an air rod, which is applied in the field of wall-climbing robots, can solve the problems of no water-cooled wall thickness measuring equipment, inconvenient maintenance and repair of the water-cooled wall, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

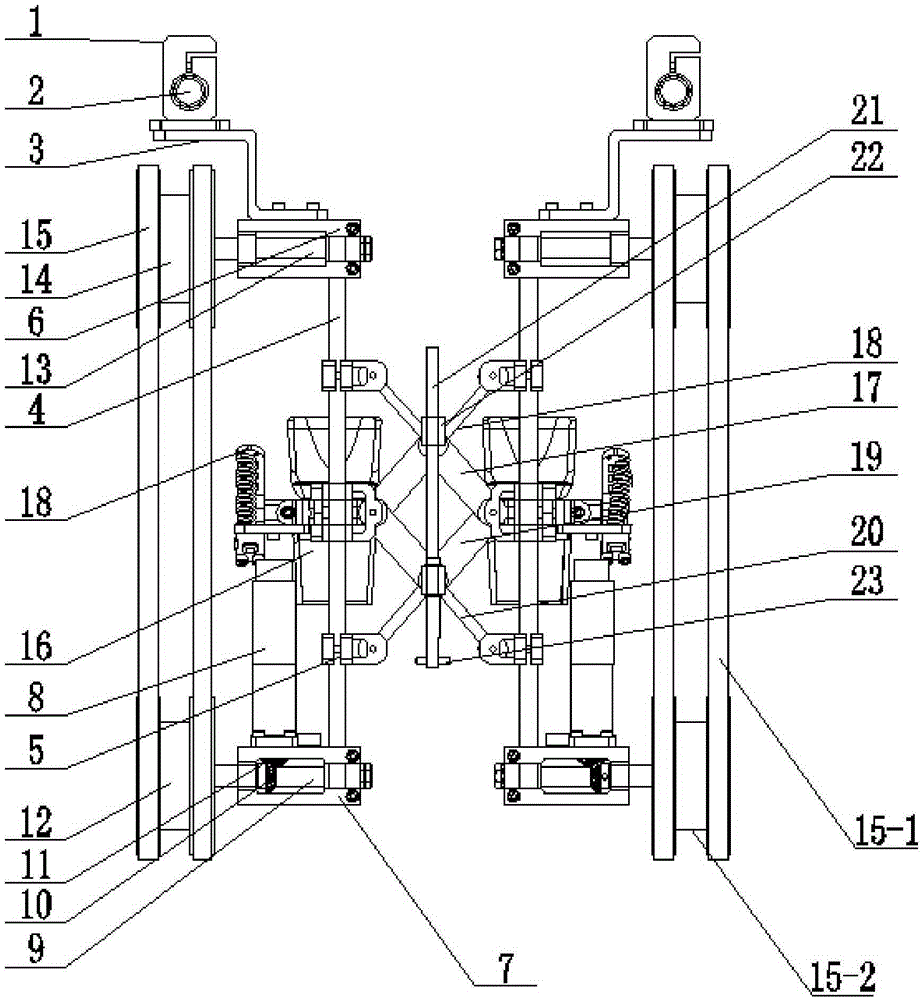

[0022] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, this embodiment is a kind of permanent magnet chain wall-climbing robot with air rod buffering, it comprises the first wall-climbing leg, the second wall-climbing leg and elastic buffer connector, the first wall-climbing leg and the second wall-climbing leg The wall-climbing legs are radially arranged left and right, and the first wall-climbing leg and the second wall-climbing leg are connected by elastic buffer connectors.

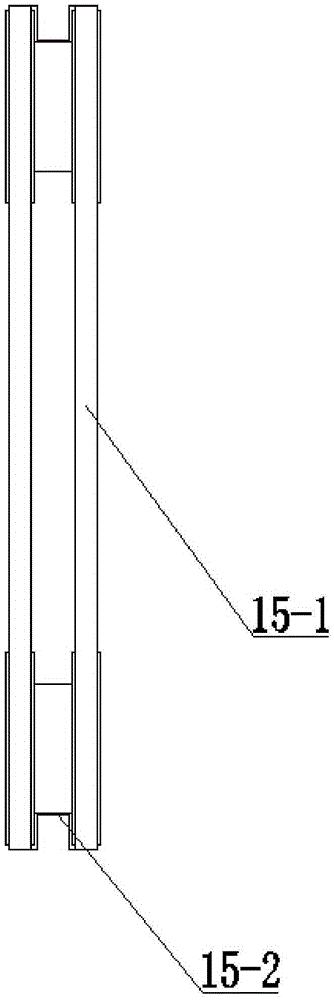

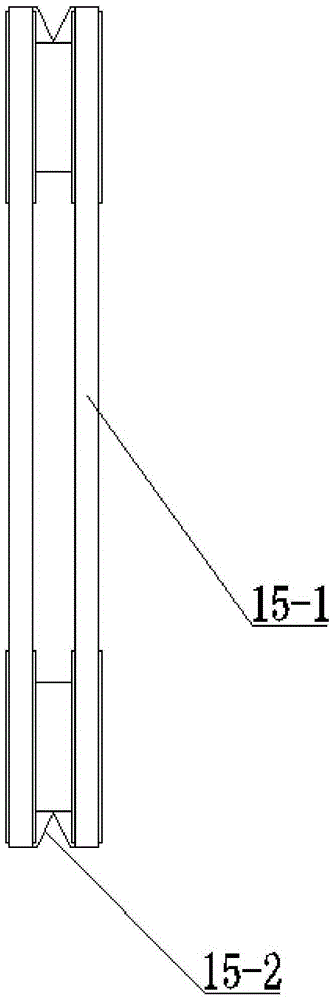

[0023] The structure of the first wall-climbing leg and the second wall-climbing leg is the same, and the first wall-climbing leg includes a probe 1, a probe sleeve 2, a probe bracket 3, at least one slide rail 4, a plurality of slide sleeves 5, a first slide rail Frame 6, second slide rail frame 7, DC servo motor 8, driving shaft 9, driving bevel gear 11, driven bevel gear 10, driving sprocket 12, driven shaft 13, driven sprocket 14, permanent magnet chain assem...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 Describe this embodiment, it also includes a manual adjustment part in this embodiment, and the manual adjustment part is installed at the upper end of the intersection of the first air rod 17 and the second air rod 18 and the intersection of the third air rod 19 and the fourth air rod 20 . This setting adds a new way to the adjustment of the buffer, especially suitable for wall climbing when the distance between the two pipes is fixed. The distance between the climbing wall is unstable when climbing the wall quickly. Other compositions and connections are the same as those in the third embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 Describe this embodiment, the manual adjusting member of this embodiment includes screw rod 21 and two nuts 22, and two nuts 22 are respectively fixedly installed on the first gas rod 17 and the intersection point of second gas rod 18 and the third gas rod 19 and the third gas rod 19 and At the crossing point of the fourth air rod 20, the screw rod 21 is a screw rod with opposite screw threads at both ends, and the screw rod 21 is screwed on the two nuts 22 to drive the two nuts 22 to move toward each other or oppositely at the same time. With such arrangement, the distance between the first wall-climbing leg and the second wall-climbing leg can be quickly adjusted through two lead screws with different rotation directions. Other compositions and connections are the same as in Embodiment 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com