One-step POY+FDY composite spinning technology

A technology of composite spinning and spinning process, applied in the field of spinning, can solve the problems of large equipment investment, high production cost, low efficiency, etc., and achieve the effect of shortening the process flow, improving efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

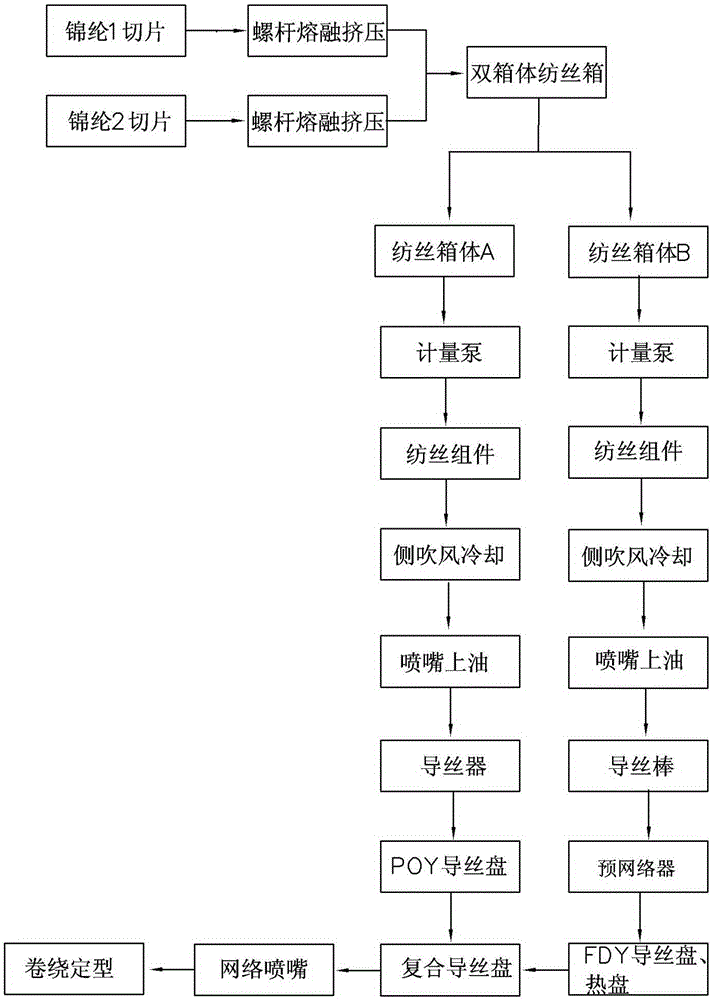

[0013] see figure 1 , the one-step POY+FDY composite spinning process in the present embodiment, comprises the following steps:

[0014] (1) The spinning process adopts a composite double-box spinning box, which corresponds to two metering pumps and two sets of spinning components respectively. Nylon 1 slices are melted and extruded by a screw, heated, melted and filtered, and then enter the spinning box A for spinning to obtain nylon 1 fiber and nylon 2 slices are melted and extruded by a screw, heated, melted and filtered, and then spun into the spinning box B to obtain nylon 2 fiber. The spinning temperature of POY is 262-270°C; the spinning temperature of FDY is 255-260°C; (2) Nylon 1 fiber is cooled and formed by side air blowing, oiled on the nozzle, and fed directly to the POY godet through the yarn guide. The winding speed of the POY godet is 4375m / min; Nylon 2 fiber is formed by side blowing cooling, After the oil nozzle is oiled, it is directly fed into the FDY gode...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap