Grouting process for preventing secondary settlement of open caisson

A caisson and grouting technology, used in caisson, infrastructure engineering, construction, etc., can solve the problem of no reliable grouting process for preventing secondary subsidence, reduce the risk of uneven settlement, reduce the secondary subsidence, etc. sinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

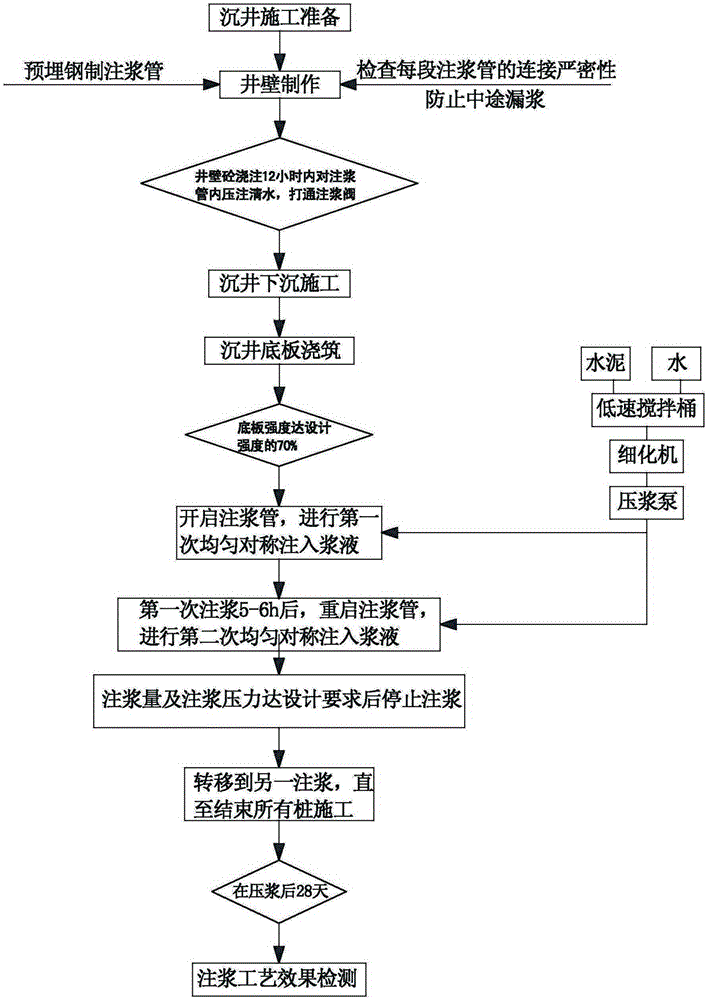

[0018] like Figure 1 to Figure 4 As shown, a grouting process for preventing secondary subsidence of caisson, the specific steps are:

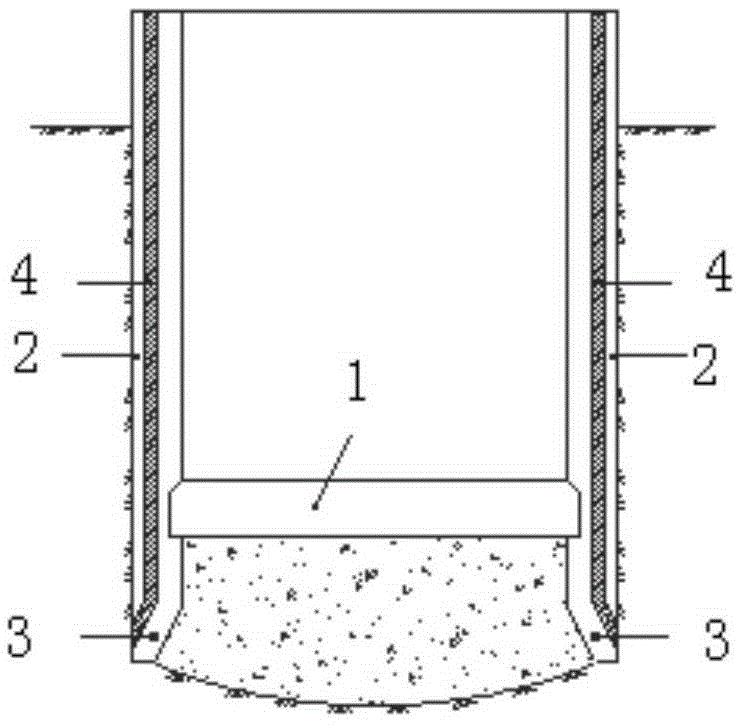

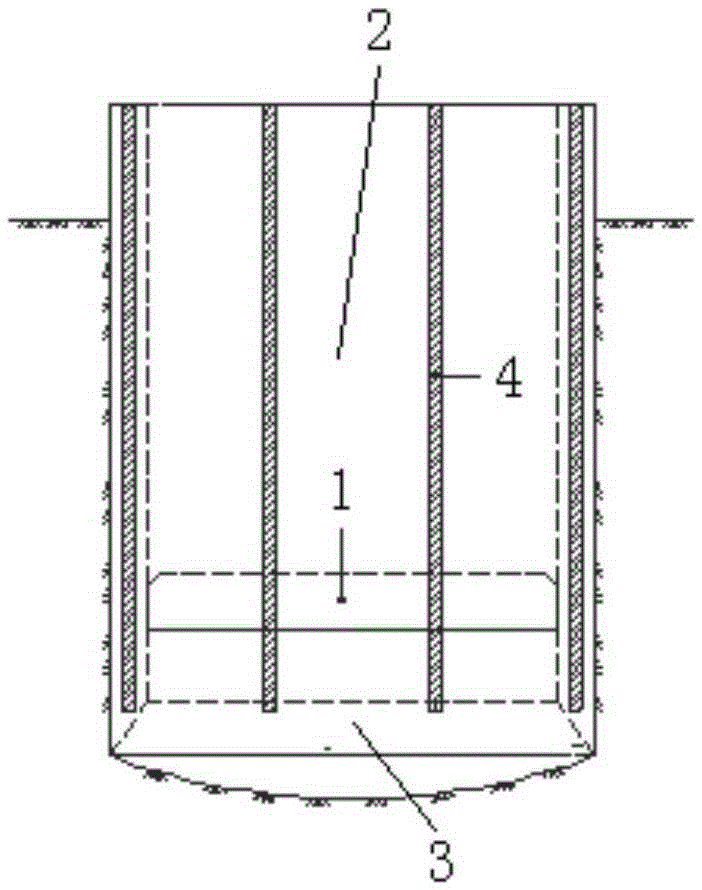

[0019] ①When the caisson wall is made, the steel grouting pipe 4 is reserved in the caisson wall 2 (see figure 2 , 3), the steel grouting pipe 4 should extend from top to bottom to the edge 3;

[0020] ② The caisson is sunk to the design elevation according to the normal construction process, and the formwork is poured into the bottom plate 1 concrete;

[0021] ③ After the concrete strength of the bottom plate 1 reaches 70% of the design strength, the first grouting is carried out through the steel grouting pipe 4 reserved in the shaft wall 2; the grouting should be added evenly and symmetrically to prevent the caisson from tilting;

[0022] ④ After the first grouting, carry out the second grouting before the initial setting of the mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com