High-voltage LED (Light-Emitting Diode) flexible light bar based on FPC-

A technology for LED flexible light strips and flexible light strips, applied in the field of flexible light strips, can solve problems such as difficulty in adjusting the size and size, and achieve the effects of improving stability and reliability, strengthening compactness, and improving environmental adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

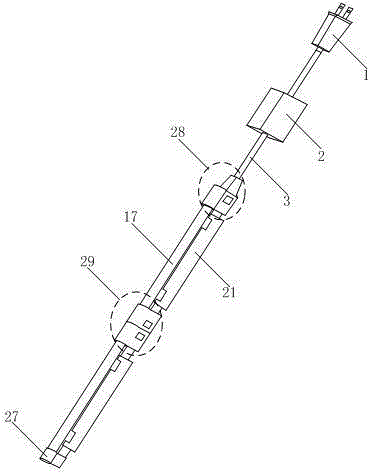

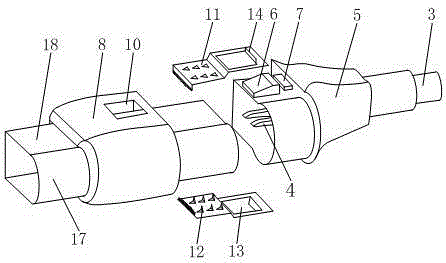

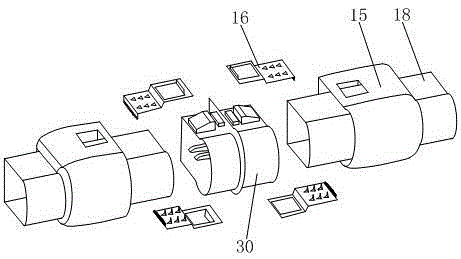

[0043] Such as figure 1As shown, the FPC-based AC LED flexible light strip disclosed by the present invention includes a power supply with a built-in control circuit, a flexible light strip structure that is movably connected to the power supply through an input terminal connection component, and is buckled in the middle of the flexible light strip structure. The installation groove, and the tail plug blocked at the end of the flexible light strip structure; the flexible light strip structure includes at least two flexible light strips extruded by FPC, and the middle-end connection components are connected between adjacent flexible light strips active connection.

[0044] The control circuit is a circuit for controlling the switch of the LED lamp, which is a prior art, and will not be described in detail here. The power supply is mainly used to convert the 220V mains power into a low voltage suitable for the LED light strip, so that the LED light strip can be directly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com