Defrosting control method with optimal comprehensive performance of air heat source pump as target

An air source heat pump, comprehensive performance technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of misjudgment or delay in defrosting control, achieve high operating efficiency, and improve indoor comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

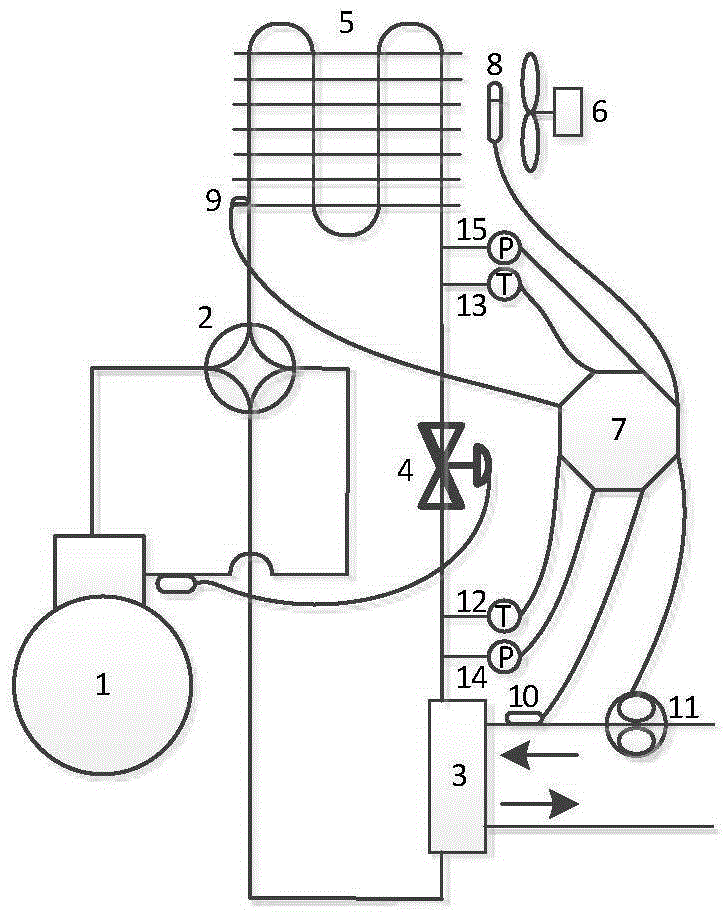

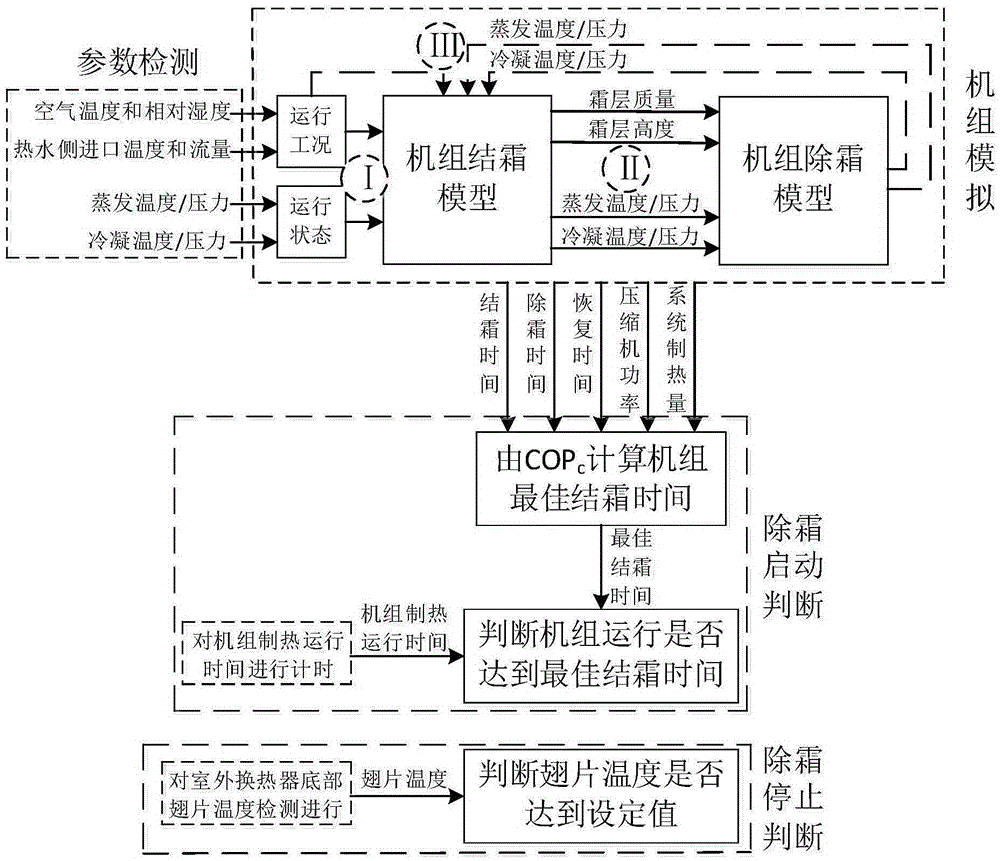

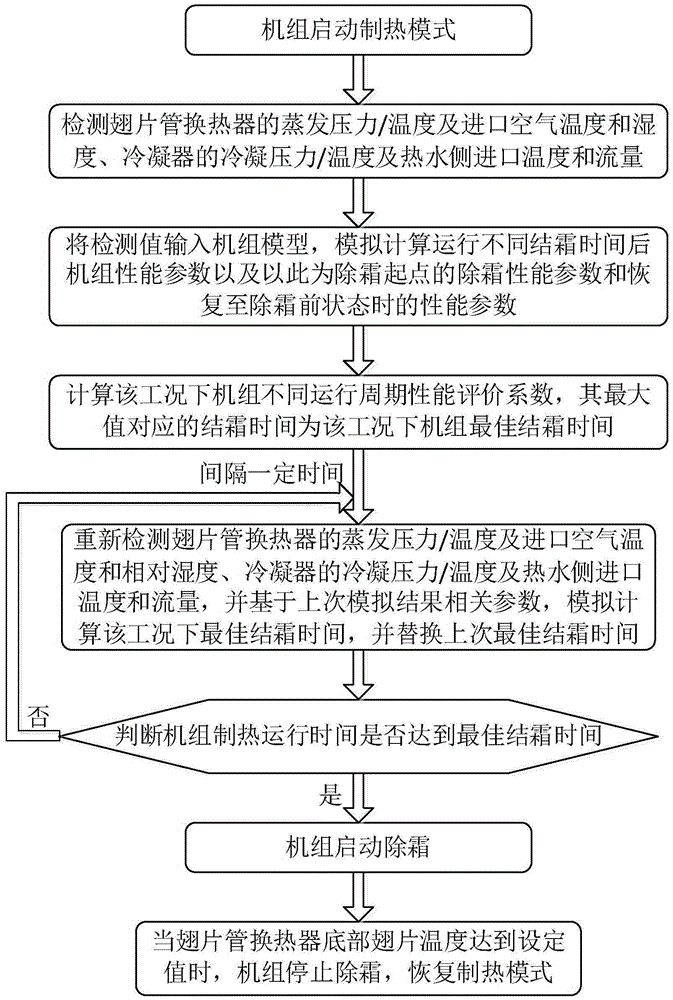

[0029] figure 1 It is the layout diagram of the defrosting control measuring points of the air source heat pump. The temperature and humidity sensor 8 is arranged at the air inlet of the finned tube heat exchanger 5 to detect the temperature and humidity of the inlet air in real time; A temperature sensor 9 detects the fin temperature of the fin tube heat exchanger. During the defrosting process, when the fin temperature reaches the set value, the unit stops defrosting; it is arranged at the inlet of the hot water side of the casing condenser 3 The second temperature sensor 10 and the flow sensor 11 detect the hot water side inlet temperature and flow in real time; the first pressure sensor 14 and the third temperature sensor 12 are arranged at the outlet of the casing heat exchanger 3; A fourth temperature sensor 13 and a second pressure sensor 15 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com