Airtightness tester for vacuum pump assembly line

An assembly line and vacuum pump technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems such as the inability to cooperate with slide rails and the inability to improve the processing speed of the vacuum pump assembly line, and achieve The effect of speeding up detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

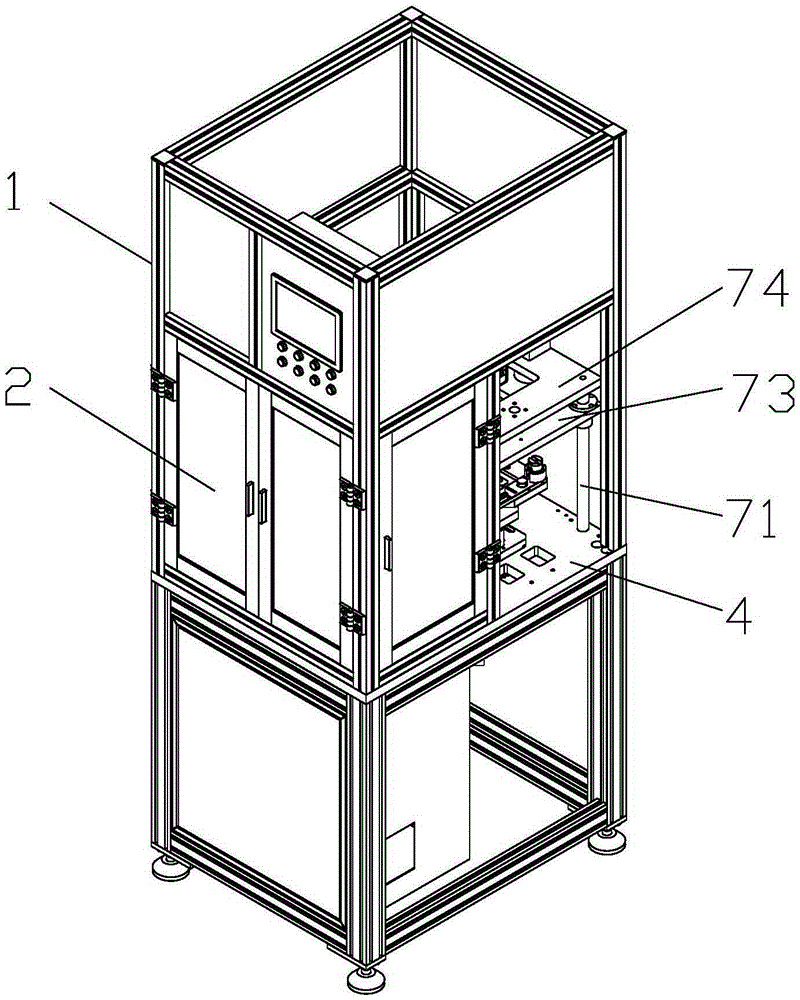

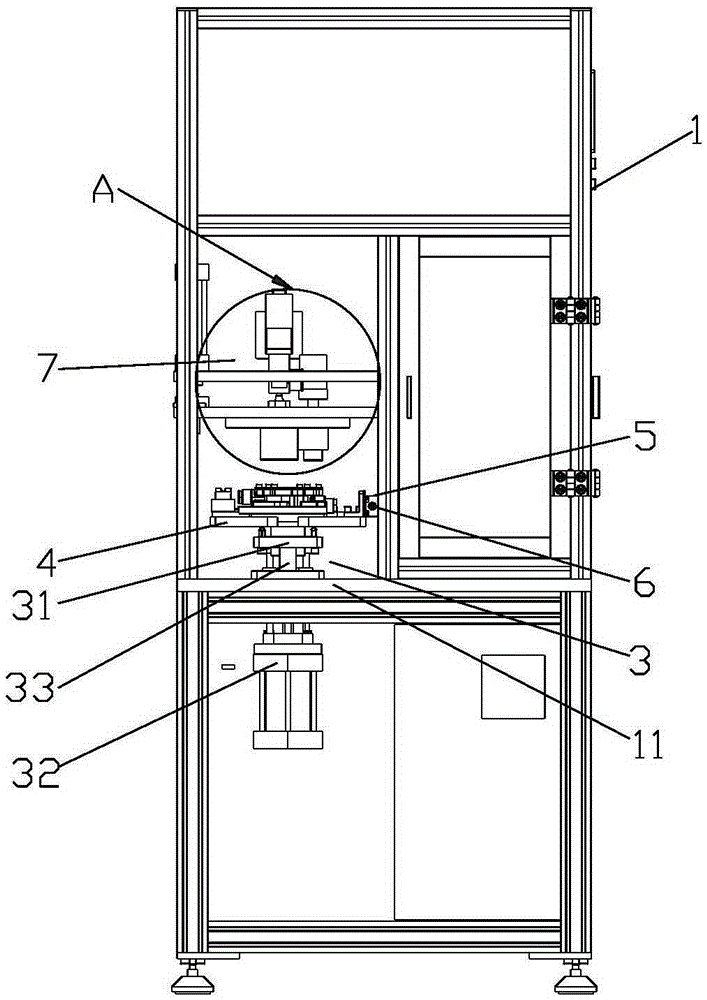

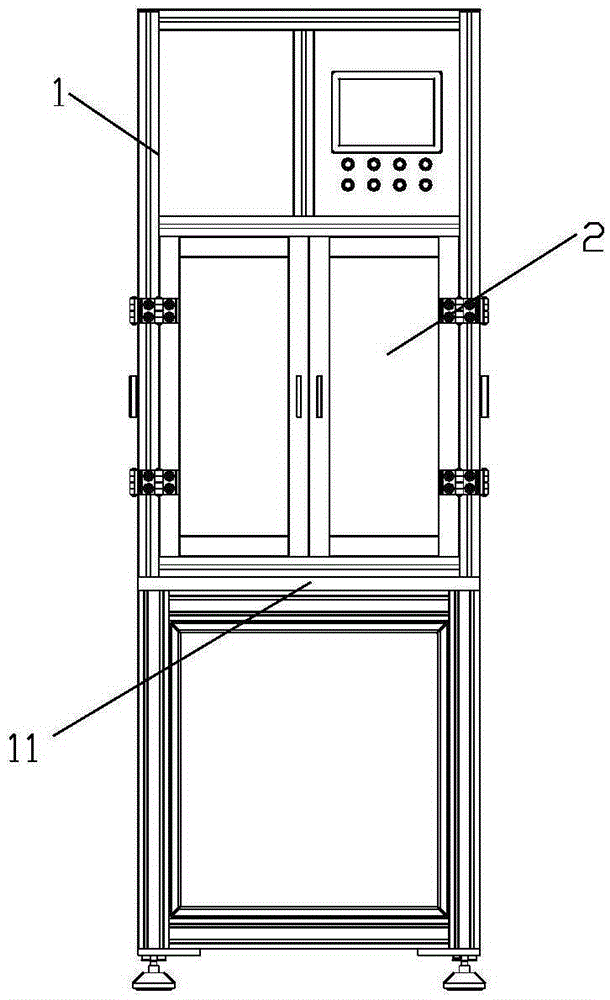

[0017] like Figure 1 to Figure 5 As shown, an air tightness testing machine used in a vacuum pump assembly line includes an assembly body 1 and a control platform 2, the assembly body 1 is provided with a bearing plate 11, and the center of the bearing plate 11 is provided with a positioning lifting mechanism 3, The top surface of the positioning lifting mechanism 3 is used to receive the station board 4 on the slide rail from the vacuum pump assembly line. To the displacement sensor 5 at the position to be checked, the positioning lifting mechanism 3 is used to lift the station board 4 from the chute of the slide rail to the position to be checked, the displacement sensor 5 is connected with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com