Reciprocating-type quick-freezing device control system

A technology of control system and quick-freezing device, applied in general control system, control/adjustment system, program control, etc., can solve the problems of inability to realize complex control, poor expansion of control system, complicated circuit, etc. The effect of low efficiency and simple system circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

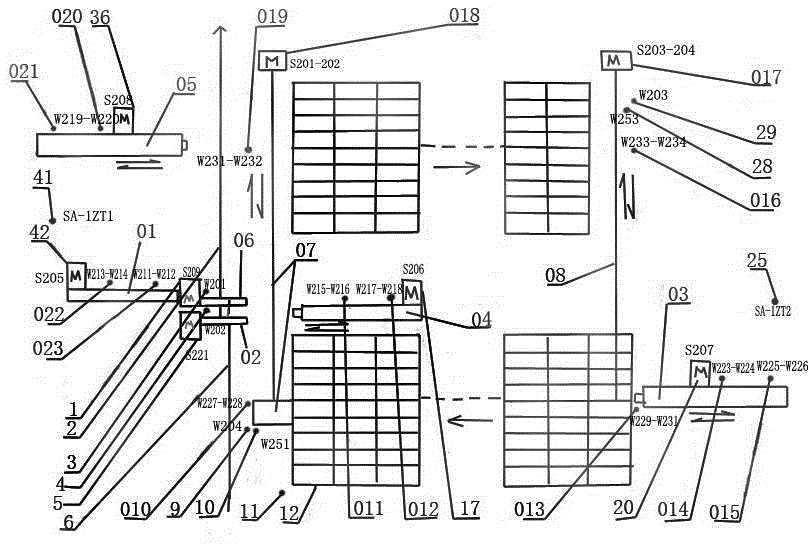

[0016] Attached below figure 1 The present invention will be further described in detail with specific embodiments.

[0017] Such as figure 1 As shown, the present invention provides a reciprocating quick-freezing system, which includes a feeding section, a discharging section, a front lifting section, a rear lifting section, a forward pushing section, a rear pushing section, a loading section, a discharging section, and a truck erection section. In the feeding section, the frame car and the feeding mechanism 06 feed the space of each layer of the frame car on the feeding conveyor line 6; The material is discharged; the rear push section pushes the frame car to the feeding section, discharge section, loading section, and unloading section. The devices in the above four sections and the devices in the front lifting section are in sequence on each layer of the frame car. Carry out the required operations, lift the trolley to the upper limit of the front lifting section after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com