A kind of preparation method of easy-tear aluminum foil

An easy-to-tear cover and aluminum foil technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of low production efficiency and poor sealing performance of the sealing film, and achieve simple steps and high production efficiency , the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

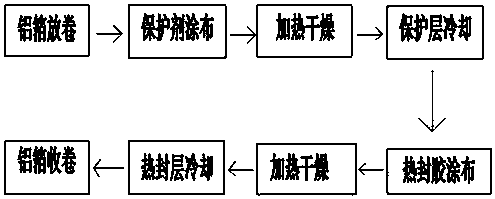

[0019] Embodiment 1: as attached figure 1 As shown, a method for preparing an aluminum foil with an easy-to-tear lid includes the following steps: (1) unwinding of the aluminum foil: the aluminum foil is divided into rolls on a machine; (2) coating of a protective agent: coating one side of the aluminum foil for The protective agent coating that forms the protective layer, the coating amount is 1.0g / ㎡; (3) heating and drying: the aluminum foil protective layer is heated and dried, and the temperature of the drying room is 190 ° C; (4) protective layer cooling: the The protective layer is cooled by cold air and cooling rollers, so that the temperature of the protective layer after cooling is 40°C; (5) Heat-sealing glue coating: coating on the other side of the aluminum foil to form a heat-sealing layer (6) Heating and drying: heat and dry the heat-sealing layer of the aluminum foil, and the temperature of the drying room is 160°C; (7) Cooling the heat-sealing layer: cooling the...

Embodiment 2

[0024] Embodiment 2: as attached figure 1 As shown, a method for preparing an aluminum foil with an easy-to-tear lid includes the following steps: (1) unwinding of the aluminum foil: the aluminum foil is divided into rolls on a machine; (2) coating of a protective agent: coating one side of the aluminum foil for The protective agent coating that forms the protective layer, the coating amount is 1.2g / ㎡; (3) heating and drying: the aluminum foil protective layer is heated and dried, and the temperature of the drying room is 210 ° C; (4) protective layer cooling: the The protective layer is cooled by cold air and cooling rollers, so that the temperature of the protective layer after cooling is 42°C; (5) Heat-sealing glue coating: coating on the other side of the aluminum foil to form a heat-sealing layer (6) Heating and drying: heat and dry the heat-sealing layer of the aluminum foil, and the temperature of the drying room is 200°C; (7) Cooling the heat-sealing layer: cooling the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com