Unidirectional single-stone-slab edge grinding device for inclined stone slab

A slate and veneer technology, applied in the field of oblique slate one-way veneer edging devices, can solve problems such as accidental injury of people, and achieve the effects of ideal grinding effect, stable operation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

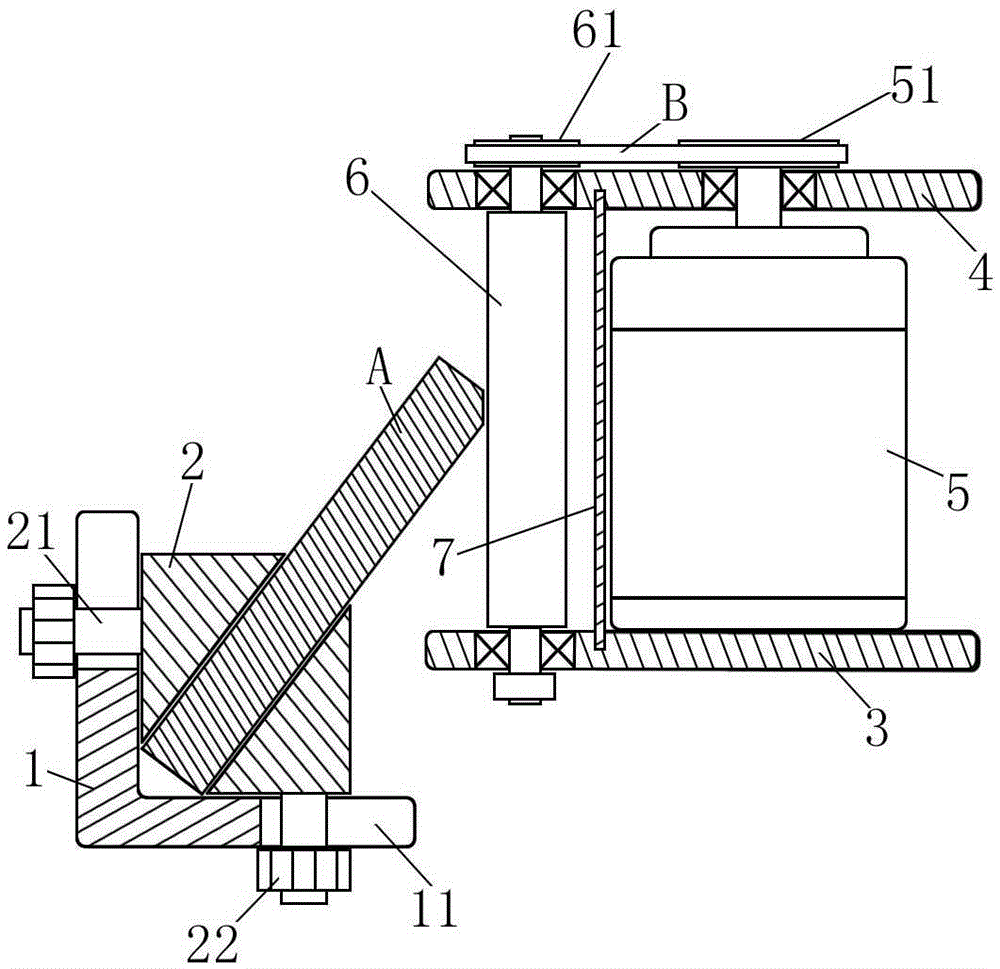

[0013] like figure 1 As shown in the figure, a one-way veneer edging device for inclined stone slabs is composed of a support angle plate 1, a plurality of triangular-shaped pressing plates 2, a machine base plate 3, a transverse shaft plate 4, a grinding roller 6, a stopper The dust plate 7 and the motor 5 are composed, which is characterized in that:

[0014] The motor 5 is erected on the base plate 3, and the transverse shaft plate 4 is arranged in parallel above the base plate 3. The shaft end of the motor 5 penetrates the transverse shaft plate 4 upward and is connected with the driving wheel 51 in series. The upper and lower ends are respectively connected in series with the transverse shaft plate 4 and the base plate 3 through bearings. The upper end of the grinding roller 6 penetrates the transverse shaft plate 4 upward and is connected in series with the driven wheel 61. The driven wheel 61 passes through the belt B. Drive connected with the driving wheel 51;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com