High-elasticity glove and production process thereof

A production process and technology of gloves, applied in gloves, clothing, applications, etc., can solve the problems of automatic glove shedding, glove elasticity and resilience, and PVC gloves are difficult to meet the requirements of use. good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

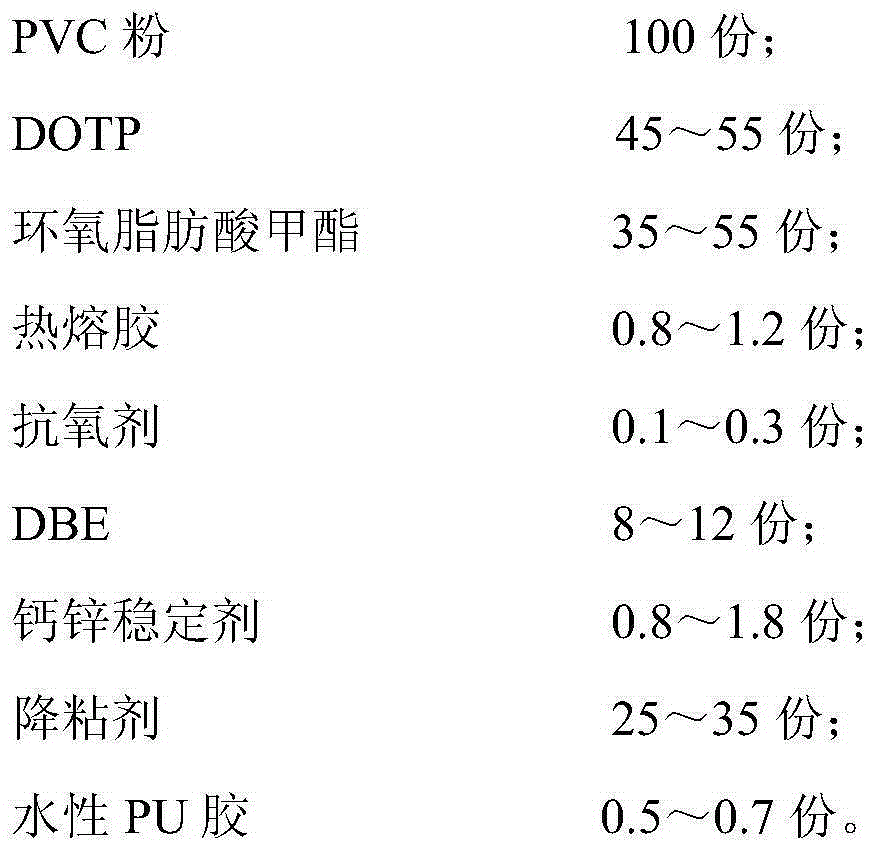

[0049] The high-elastic gloves described in this embodiment are made of the following raw materials in parts by weight:

[0050]

[0051]

[0052] Its production process includes the following steps:

[0053] (1) Primary ingredients: a. Add antioxidant, hot melt adhesive, DBE and 8 parts of viscosity reducer to a heated stirring tank, start stirring, raise the temperature to 120°C and stir for 1 hour at a stirring speed of 900r / min. Antioxidant and hot-melt adhesive are completely dissolved; b, DOTP and epoxy fatty acid methyl ester are added in another stirring kettle, after stirring 30min, drop into PVC powder, obtain PVC paste, throwing PVC powder speed is 2.5t / h, The stirring speed is 1350r / min, and the eccentric stirring speed is 1500r / min; c. After adding calcium zinc stabilizer and 6 parts of viscosity reducer to the PVC paste, keep stirring at 1500r / min for 2h; d. After the material is cooled to 45°C, it is added to the material prepared in step c, and stirred to ...

Embodiment 2

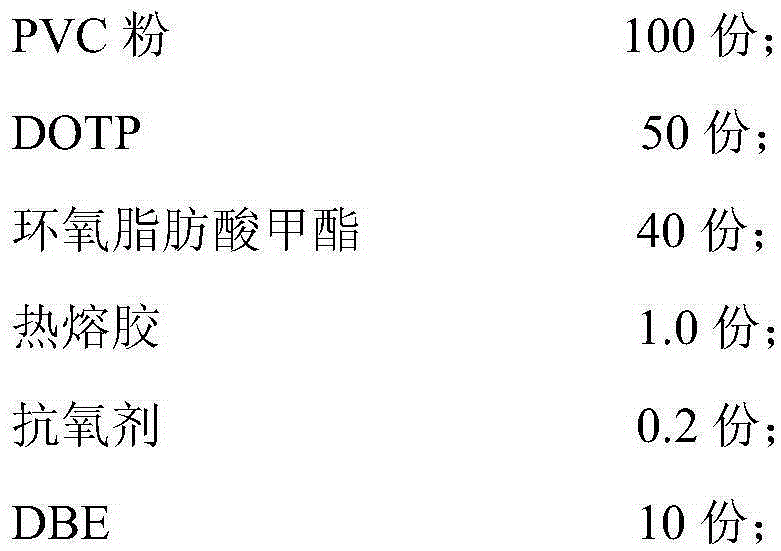

[0067] The high-elastic gloves described in this embodiment are made of the following raw materials in parts by weight:

[0068]

[0069] Its production process includes the following steps:

[0070] (1) Primary ingredients: a. Add antioxidant, hot melt adhesive, DBE and 12 parts of viscosity reducer to a heated stirring tank, start stirring, heat up to 120°C and stir for 1 hour at a stirring speed of 1000r / min. Antioxidant and hot-melt adhesive are completely dissolved; b, DOTP and epoxy fatty acid methyl ester are added in another stirring kettle, after stirring 30min, drop into PVC powder, obtain PVC paste, throwing PVC powder speed is 3.4t / h, The stirring speed is 1500r / min, and the eccentric stirring speed is 1500r / min; c. After adding calcium zinc stabilizer and 10 parts of viscosity reducer to the PVC paste, keep stirring at 1500r / min for 2h; d. After the material is cooled to 55°C, it is added to the material prepared in step c, and stirred to obtain a batch of ing...

Embodiment 3

[0084] The high-elastic gloves described in this embodiment are made of the following raw materials in parts by weight:

[0085]

[0086] Its production process includes the following steps:

[0087] (1) Primary ingredients: a. Add antioxidant, hot melt adhesive, DBE and 10 parts of viscosity reducer to a heated stirring tank, start stirring, heat up to 120°C and stir for 1 hour at a stirring speed of 950r / min. Antioxidant and hot melt adhesive are completely dissolved; b, DOTP and epoxy fatty acid methyl ester are added in another stirring kettle, after stirring for 30min, put in PVC powder, get PVC paste, throw in PVC powder speed is 3t / h, stir The rotating speed is 1420r / min, and the rotating speed of eccentric stirring is 1500r / min; c. After adding calcium zinc stabilizer and 8 parts of viscosity reducer to the PVC paste, keep stirring at a rotating speed of 1500r / min for 2h; d. Mix the material prepared in step a After cooling down to 50°C, add it to the material prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com