Cylinder with tetragonal prism-shaped piston rod

A square cylindrical, piston rod technology, applied in the direction of piston rod, engine seal, mechanical equipment, etc., can solve the problems of increasing the space occupied by the equipment and the weight of the equipment itself, increasing the production cost of the equipment, reducing the accuracy of the equipment, etc. The weight of the small equipment itself, reducing the cost of production equipment, and improving the accuracy of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

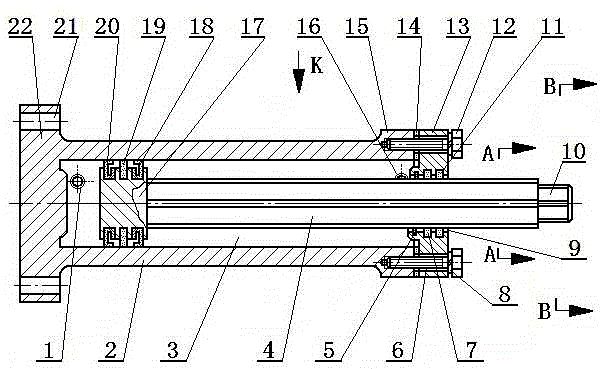

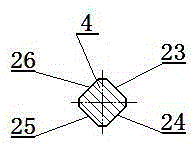

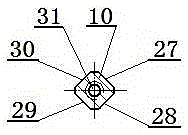

[0027] Embodiment: As shown in the figure, the details of the specific device proposed by the present invention are: including cylinder body (2), cylinder head (13), first annular sealing ring (14), piston (17), first bowl-shaped Sealing ring (18), the second annular sealing ring (19) and the second bowl-shaped sealing ring (20) are a cylinder with a square cylindrical piston rod, and the central circular hole (3) of the cylinder body (2) is provided with Piston (17), the right end of the piston (17) is provided with a square cylindrical piston rod (4) with an integral structure with the piston (17), and the right end of the square cylindrical piston rod (4) passes through the centerline of the cylinder head (13) respectively The square sealing ring A (5), the square sealing ring B (7) and the square sealing ring C (11) in the square hole (9) on the top are exposed outside the right end surface of the cylinder head (13) behind.

[0028] The right end of the square cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com