Damping-optimization design method of panoramic observation mirror equipment structure

An optimized design and observation mirror technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as backward detection range and accuracy, unclear optimization design direction, long new product development cycle, etc., to reduce blindness, The effect of shortening the development period and reducing the assessment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

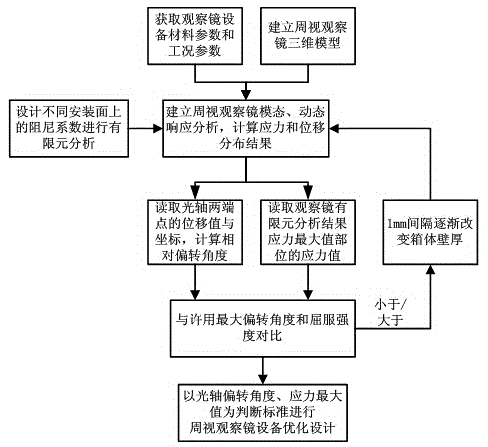

[0025] Such as figure 1 as shown,

[0026] Step 1. Obtain the material parameters and working condition parameters of the observation mirror equipment. The parameters required for finite element simulation analysis are as follows in Table 1 and Table 2; including: ①Material parameters: density ,Elastic Modulus , Poisson's ratio μ; ② Operating parameters: impact load acceleration, period, vibration frequency range, acceleration. ③The maximum allowable relative offset angle between the two ends of the optical axis of the observation mirror is 0.01°

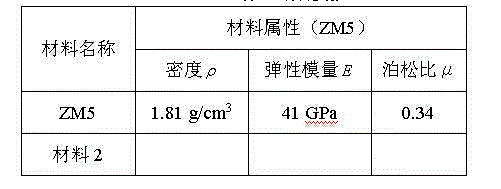

[0027] Table 1 Material parameters

[0028]

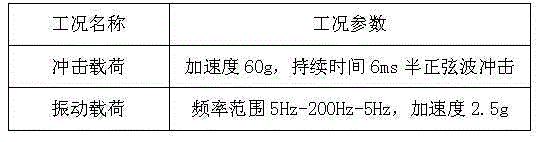

[0029] Table 2 Working condition parameters

[0030]

[0031] Step 2. Use the 3D modeling software to establish a 3D model of the periscope observation mirror, and import the 3D model into the finite element simulation analysis software to generate a corresponding geometric model.

[0032] Step 3. Establish a finite element simulation analysis model, and select the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com