No-tillage cover crop grinding device

A cover crop and hydraulic cylinder technology, applied in the field of agricultural machinery, can solve problems such as poor seeding effect, pesticide residues, congestion, etc., and achieve the effect of saving the use of chemical herbicides and saving farming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

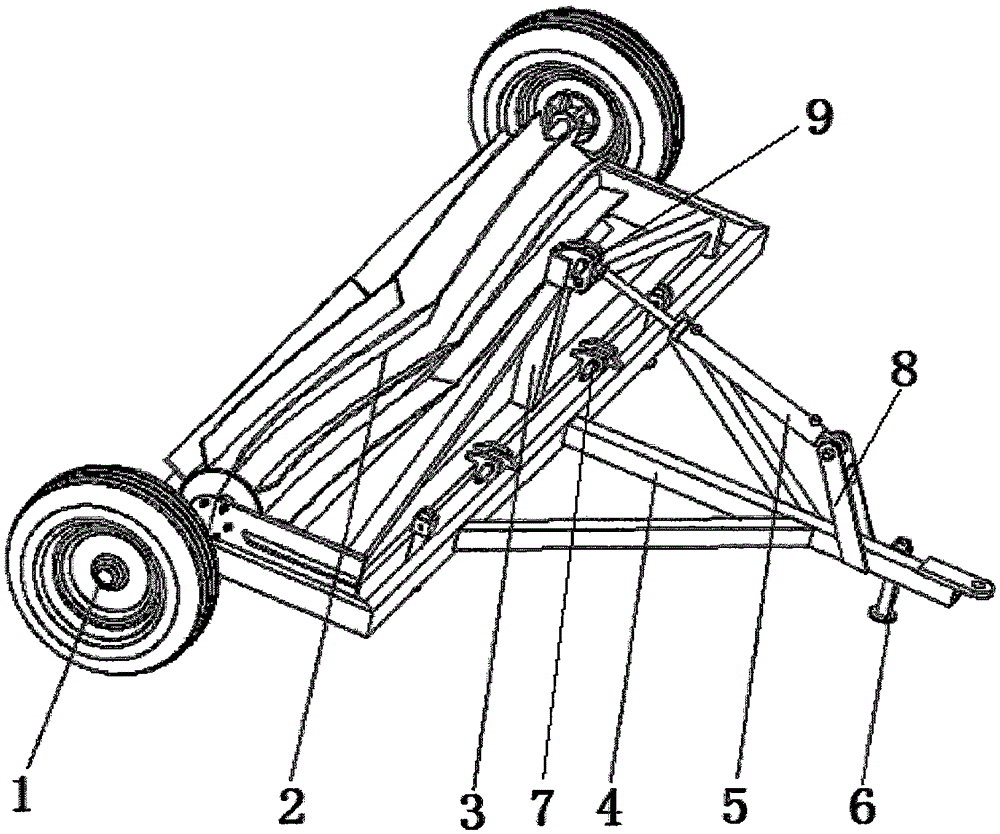

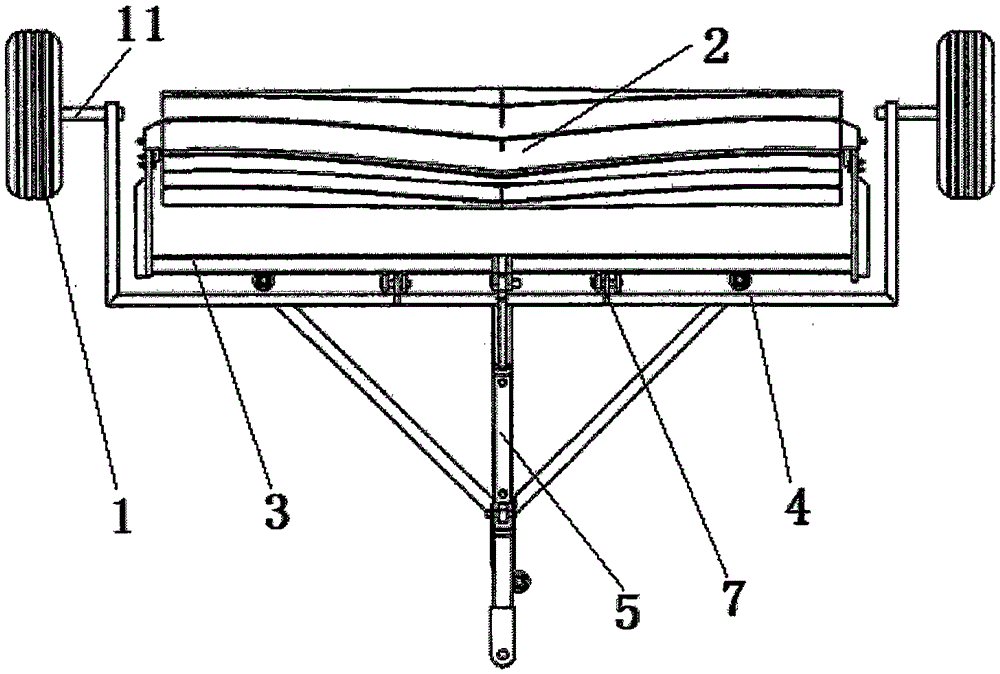

[0013] see Figure 1-3 , the specific embodiment is realized by adopting the following technical scheme, which includes supporting traveling wheels 1, rolling and bending rollers 2, roller support connecting frame 3, traction frame 4, hydraulic cylinder 5 and support frame 6, and described traction frame 4 is docked with the tractor, the roller support connecting frame 3 and the traction frame 4 are hingedly connected through the hitch 7, and the roller support connecting frame 3 can be adjusted to rotate around the hitch 7 through the hydraulic cylinder 5, and the hydraulic cylinder One end of 5 is fixed on the traction frame 4 through the first cylinder base 8 and is rotatably connected with the first cylinder base 8, and its piston shaft end is fixed on the roller support connecting frame 3 through the second cylinder base 9 and connected with the second cylinder base 9 Rotational connection and cooperation, the middle parts of the two ends of the rolling and bending roller...

Embodiment 2

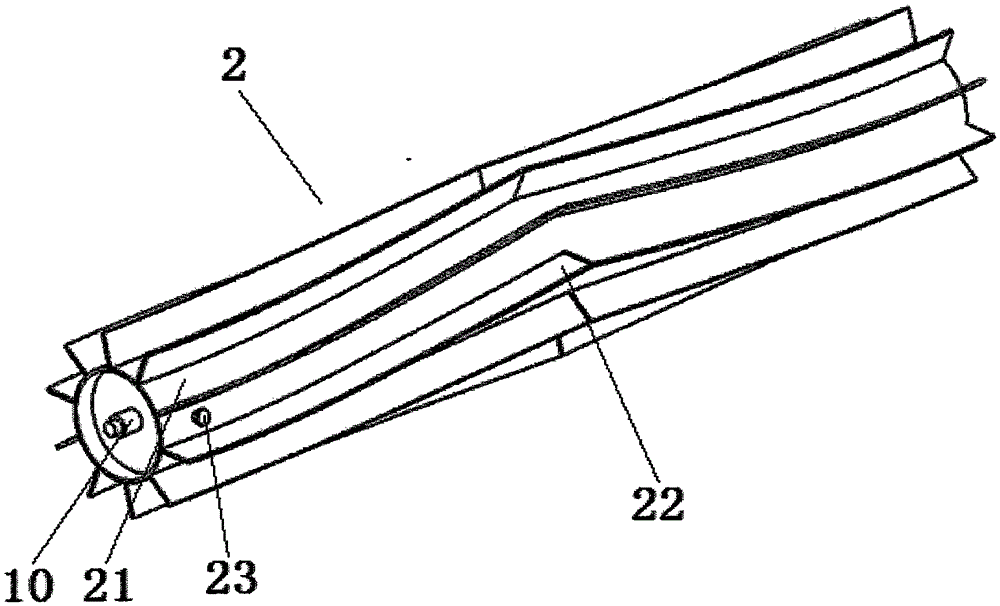

[0016] see Figure 1-3 , the device is articulated with the tractor through the traction frame 4, the roller support connecting frame 3 and the traction frame are hinged through the hitch device 7, and the roller support connecting frame 3 can be adjusted to rotate around the hitch device 7 through the hydraulic cylinder 5, thereby adjusting the rolling Bending roller 2 position, rolling bending roller 2 is supported and connected by the rolling bearing on the roller support connecting frame 3. The rolling and bending roller 2 is mainly made of a 10mm thick steel plate bent into a cylinder 21 with a diameter of 300mm and a length of 3050mm, and 12 steel plates with a thickness of 9mm and a height of 100mm are evenly distributed on the outer surface of the cylinder 21 in the circumferential direction as rolling blades 22 Composition, the rolling blade 22 is welded and fixedly connected to the outer surface of the cylinder 21, and the shape of the rolling blade 22 is focused on ...

Embodiment 3

[0018] see Figure 1-3 , at an appropriate time before planting economic crops, the device is connected to the tractor through the traction frame 4, and during road transportation, the roller support connecting frame 3 and the rolling and bending roller 2 are lifted through the hydraulic cylinder 5 without contacting the ground , when entering the cover crop operation plot, put down the control roller support connecting frame 3 and the rolling and bending roller 2, at this time, the roller supporting connecting frame 3 and the horizontal main beam of the traction frame 4 are parallel, and the device is pulled by a tractor to cover crops in the field Walking upwards, the rolling and bending roller 2 is driven and rotated by the surface of the cover crop itself. When it encounters the stalk of the cover crop, it will roll and bend the stalk without breaking it. After the operation, the cover crop (rye, Sudan grass) will be flat and lodging shape, and died due to mechanical and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com