Efficient concentrator for powder production

A concentrator and high-efficiency technology, which are applied in the high-efficiency and energy-saving spray-type single-effect concentrator, the production of products, and the production and processing of Inonotus obliquus product powder, can solve the problem of insufficient and effective use of energy, The concentrator has problems such as long consumption time and low production efficiency, which can increase the probability of collision and heat exchange, prolong the residence time, and increase the heating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described below in conjunction with the accompanying drawings. The specific schemes described in the following examples are only for illustrating the content of the present invention, and are not intended to limit the present invention.

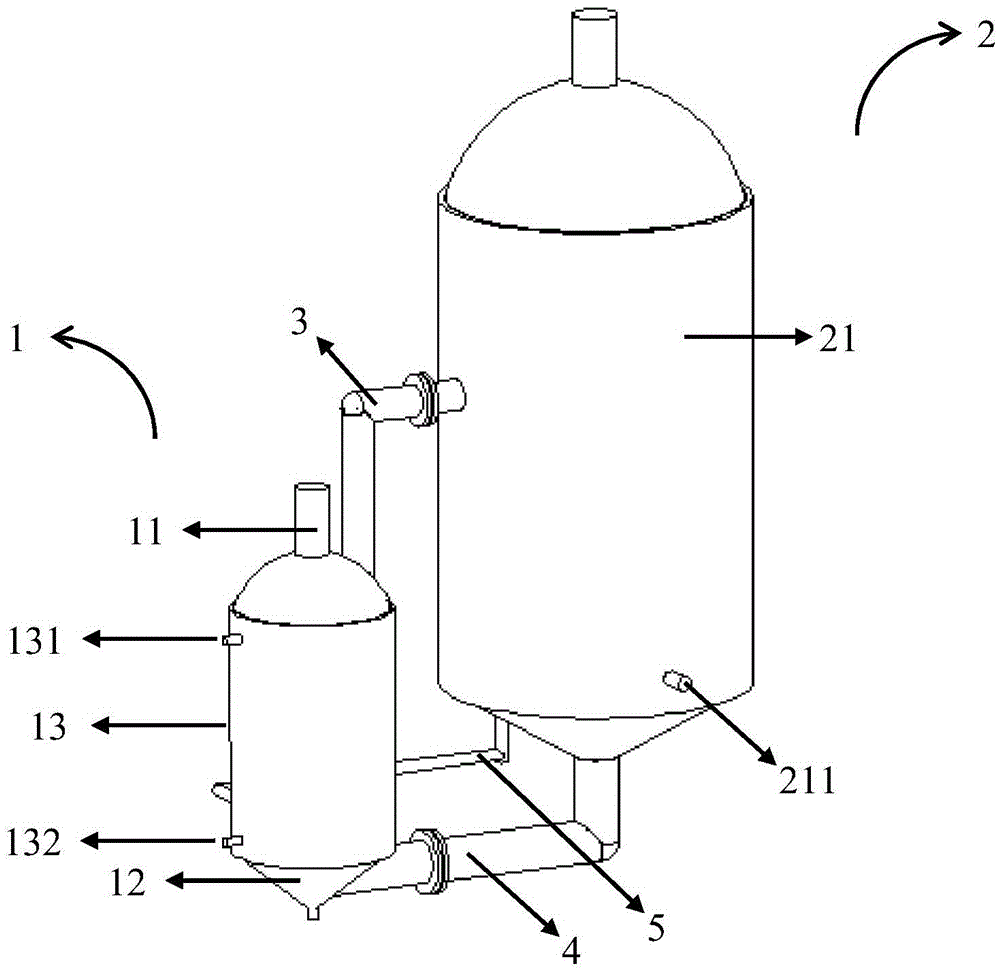

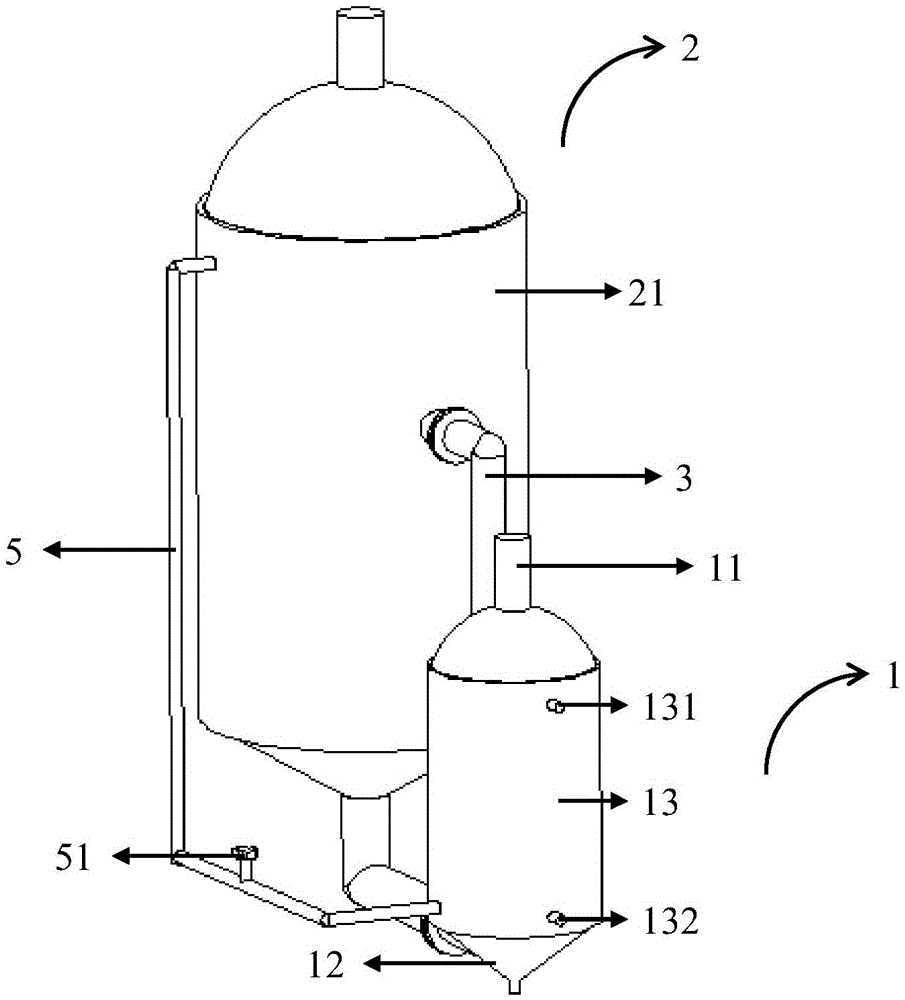

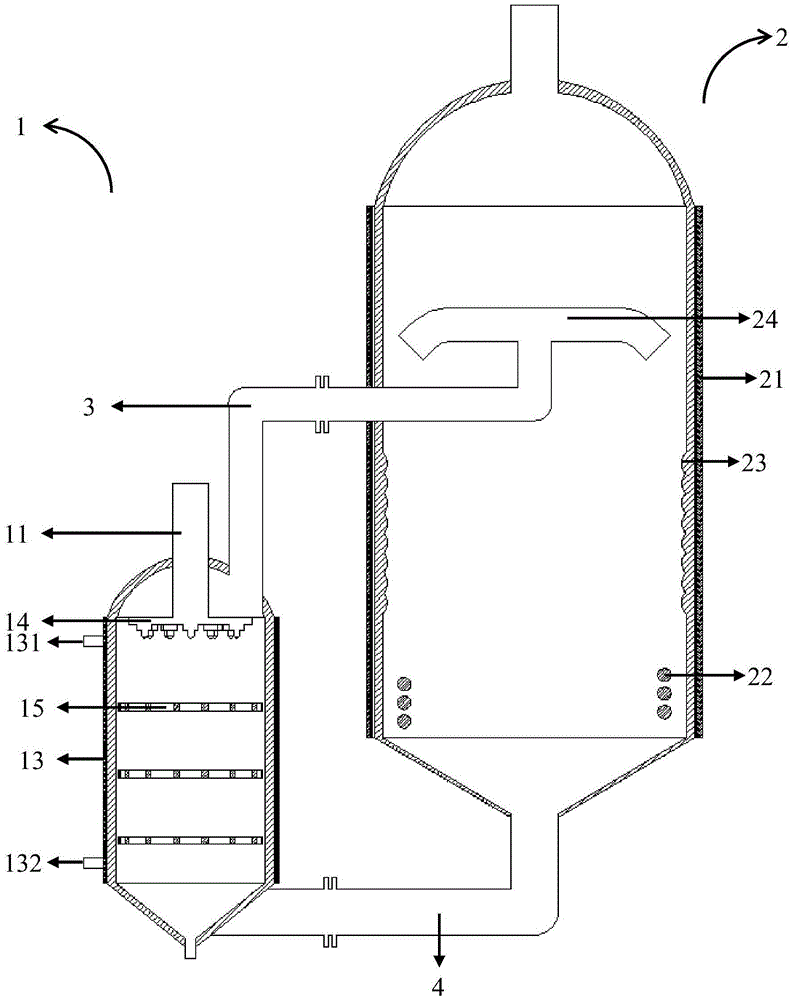

[0025] The structure created by the present invention is as Figure 1-6 As shown, it includes a heating chamber 1 and an evaporation chamber 2. The top of the heating chamber 1 is provided with a feed port 11, and the bottom is provided with a paste collecting mechanism 12. The top of the heating chamber 1 is also provided with a The discharge pipe 13, the bottom of the evaporation chamber 2 is provided with a return pipe 14 communicated with the paste collection mechanism 12 of the heating chamber 1, for the concentrated liquid to flow back into the paste collection mechanism 12 after evaporation for paste collection.

[0026] Wherein, the outer wall of the heating chamber 1 is provided with a first jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com