Heat conveying structure of coir mat dryer

A technology of conveying structure and drying machine, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of slow drying speed and uneven drying, and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

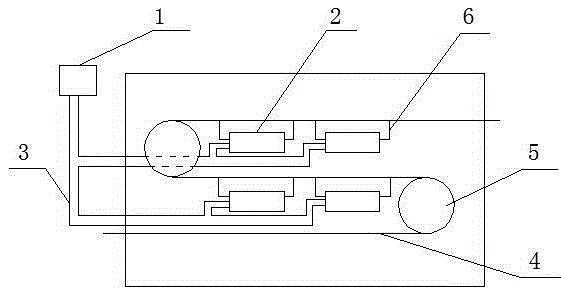

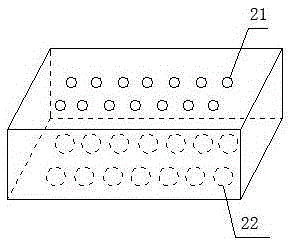

[0014] like figure 1 , figure 2 The heat transmission structure of the palm mat dryer shown includes a boiler, a fan 1, a transmission pipe 3, a bracket 6, an air distribution plate 2, and a palm mat transmission base 4. The air distribution plate 2 is hollow inside and has a hot air At the entrance, several small holes are set on the upper and lower layers of the air distribution plate 2, and the boiler heating fuel provides hot air. One end of the fan 1 is connected to the hot gas outlet of the boiler, one end is connected to the transmission pipe 3, and the other end of the transmission pipe 3 is connected to the hot air inlet of each air distribution plate 2 , start the fan 1 to transmit the hot air produced by the boiler to the air distribution plate 2 through the transmission pipe 3, the inside of the air distribution plate 2 is hollow, and the heat is emitted through the small holes of the air distribution plate 2, and the palm transmitted on the brown mat transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com