Machining method of flange plate taper sleeve

A processing method and technology of taper sleeves, applied in the field of processing flange taper sleeves, can solve the problems of not disclosing inner and outer taper sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

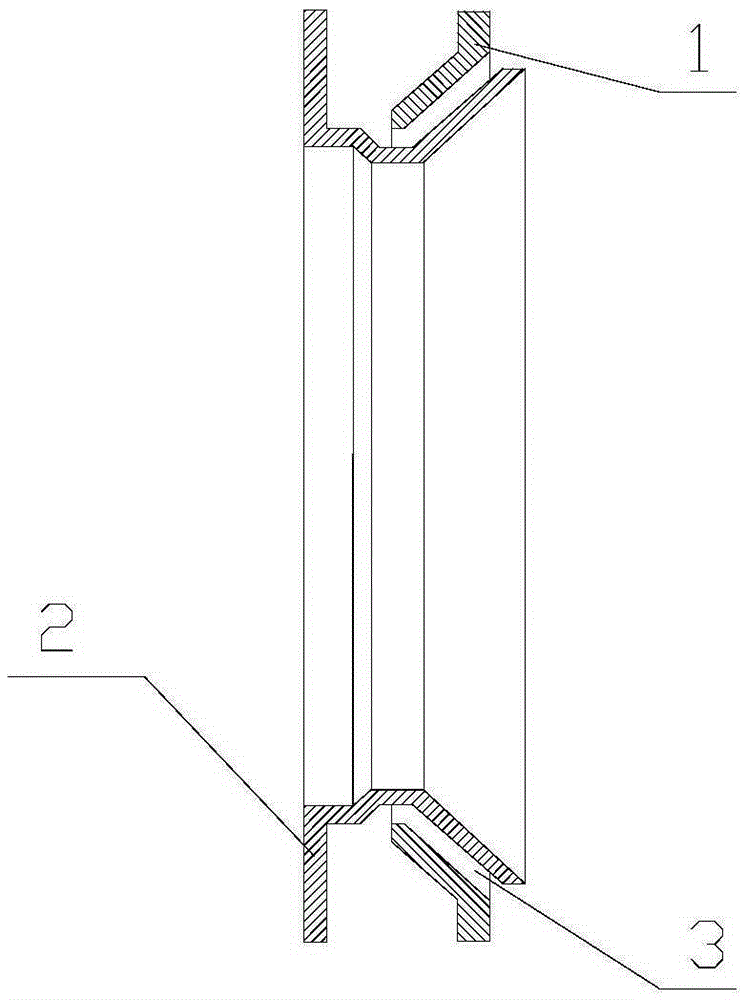

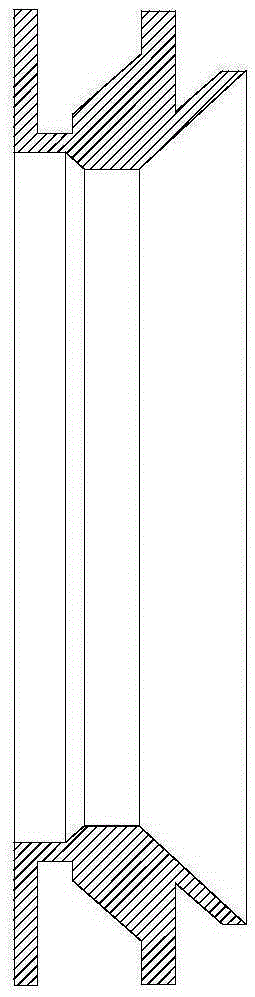

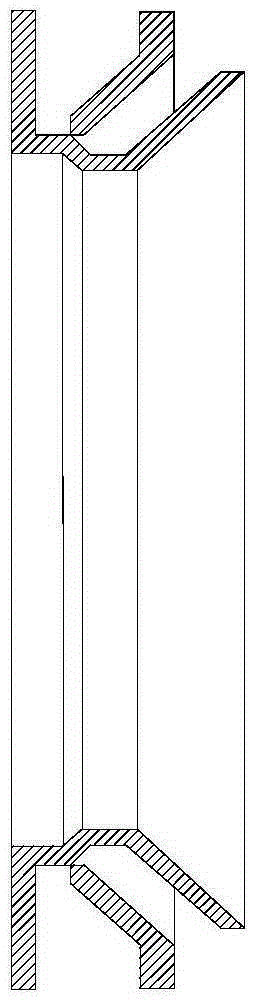

[0024] A flange taper sleeve for a helicopter reducer includes an inner taper sleeve and an outer taper sleeve. The thickness of the inner taper sleeve and the outer taper sleeve are both 4.35±0.05mm, the taper is 81°, and the outer taper sleeve is located outside the inner taper sleeve. When in use, the distance between the inner and outer shaft sleeves perpendicular to the tapered surface is 4.35mm. On this basis, the maximum distance that the outer tapered sleeve can move axially to the left is 5.36mm. The processing process includes the following steps:

[0025] 1. According to the maximum displacement distance of the outer taper sleeve 1, calculate the maximum width value of the annular chute 3: 5.36×Sin(81° / 2)+4.35=7.832mm

[0026] 2. Rough machining: the forging is processed, and the other positions except the annular chute are processed to the required size, and the position of the annular chute is processed. The thickness after processing is the thickness of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com