A thin and high-precision hydrostatic rotary table structure

A rotary table, high-precision technology, used in manufacturing tools, large fixed members, metal processing equipment, etc., can solve problems such as the complexity of oil circuit design, save axial dimensional space, enhance concentration, and reduce shaft thickness effect on size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above solution will be further described below in conjunction with specific embodiments.

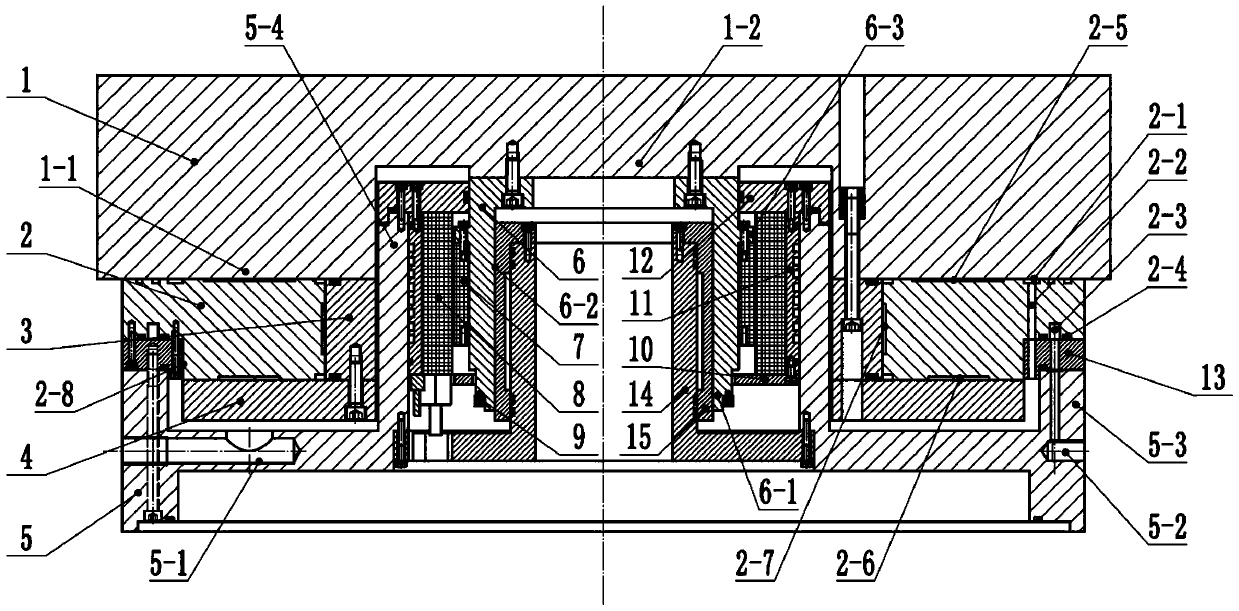

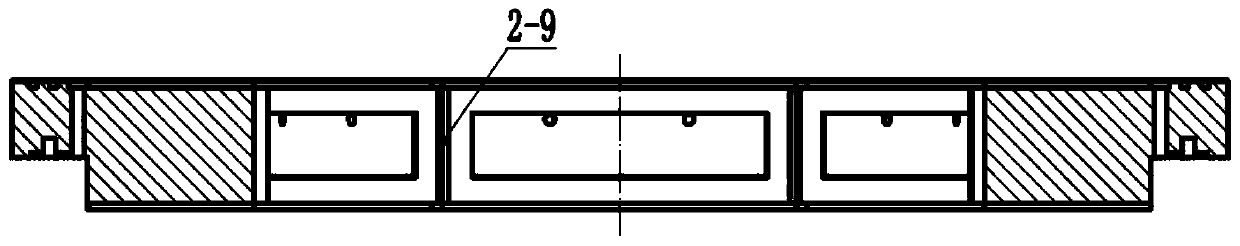

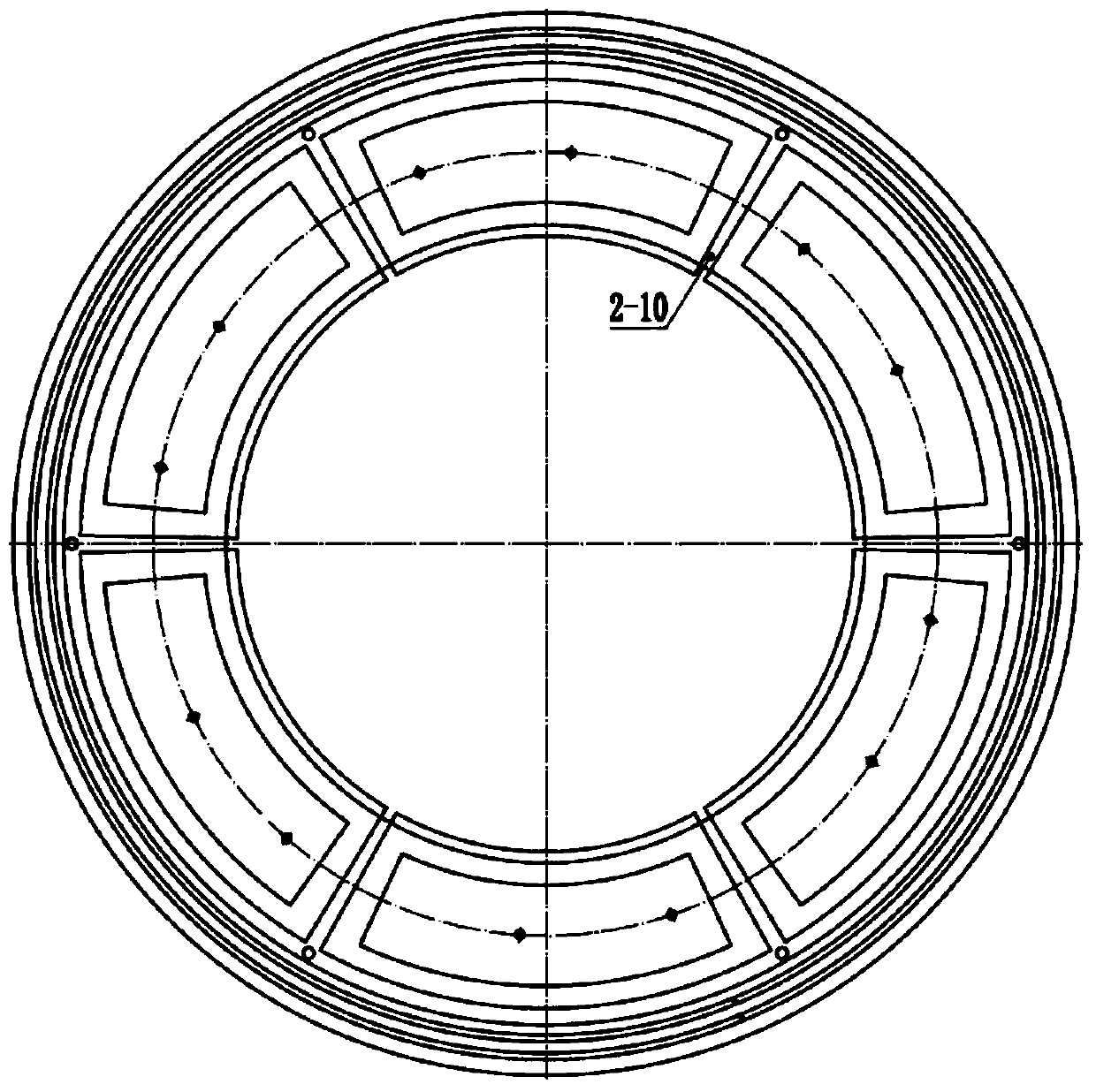

[0026] Such as figure 1 As shown, a thin high-precision hydrostatic rotary table structure. Including table top 1, bearing bush 2, rotor shaft 3, thrust plate 4, base 5, rotor fixing piece 6, motor rotor 7, motor stator 8, circular grating encoder 9, magnetic isolation ring 10, stator water jacket 11, Stator rib 12, oil inlet cover plate 13, brake fixing part 14, brake 15.

[0027] The motor rotor 7 is fixed on the rotor fixing part 6 through the flange 6-3, and the rotor fixing part 6 is directly connected with the inner groove 1-2 on the table top 1.

[0028] The half section of the base 5 is U-shaped structure, the outer circular platform 5-3 is connected with the upper seam 2-8 of the bearing bush 2, the inner circular platform 5-4 is connected with the stator rib 12 by screws, and the stator rib 12 and the stator water jacket 11 pass through Screws are connected, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com