Integrated double-sided mirror

A double-sided mirror, integrated technology, used in installation, optics, instruments, etc., can solve the problems of large total mass and axial size of the main mirror and four mirrors, large emission resources, etc., to save axial size space, reduce Mirror quality, the effect of saving launch resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In conjunction with accompanying drawing and example, the specific embodiment of the present invention is described in further detail:

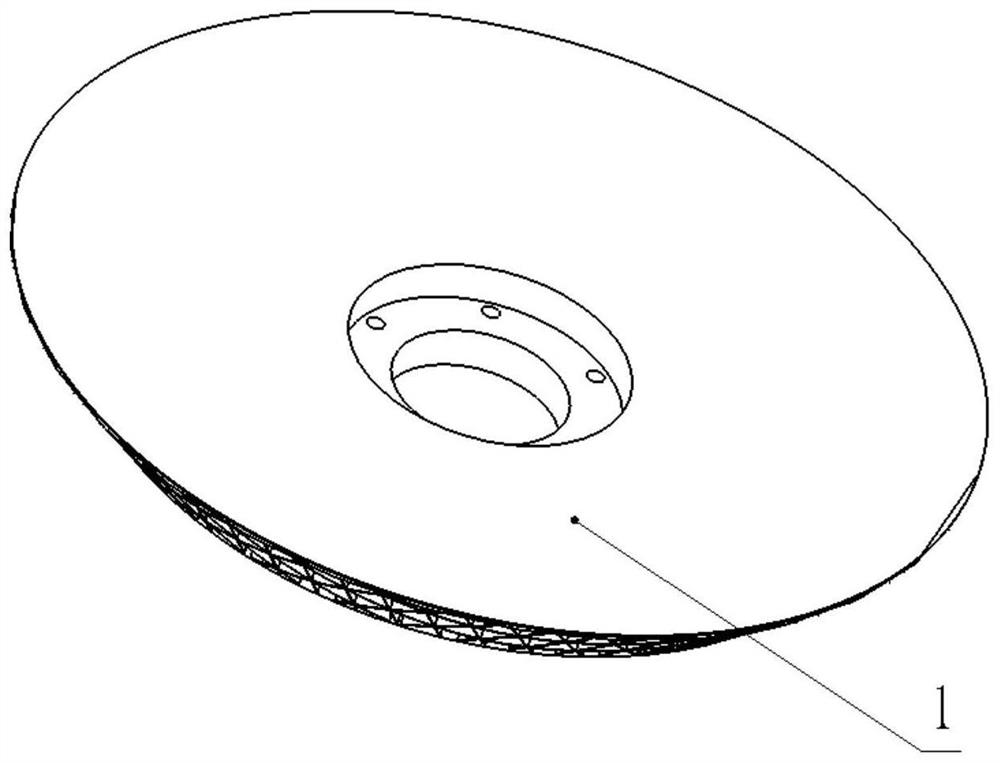

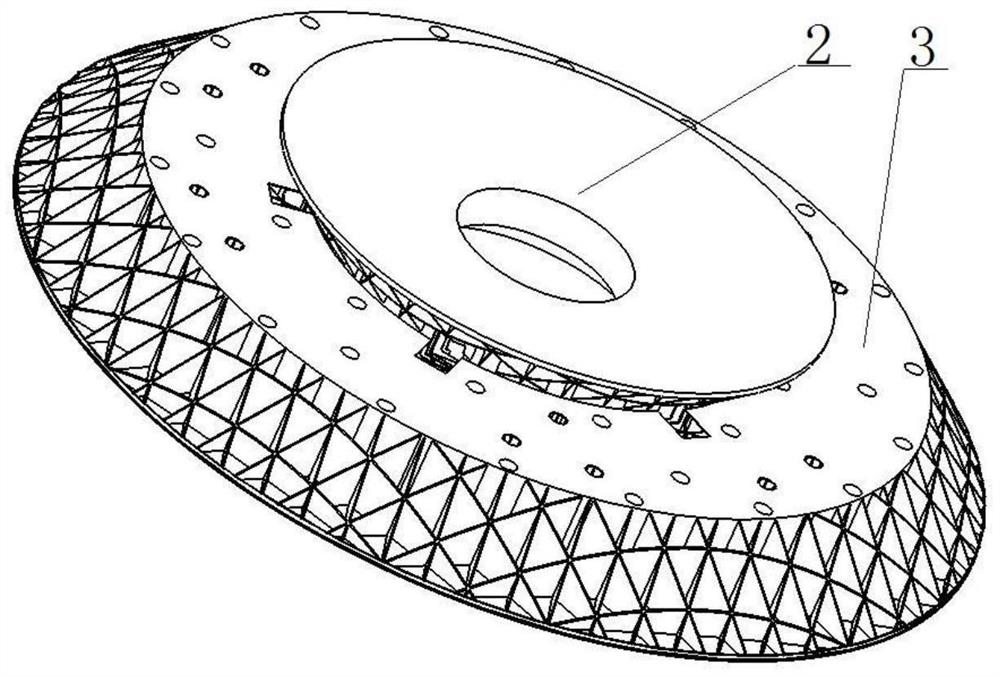

[0018] An integrated double-sided mirror is designed, in which two large mirrors are back-to-back and share the same support structure, specifically including A mirror 1, B mirror 2 and a closed plate 3.

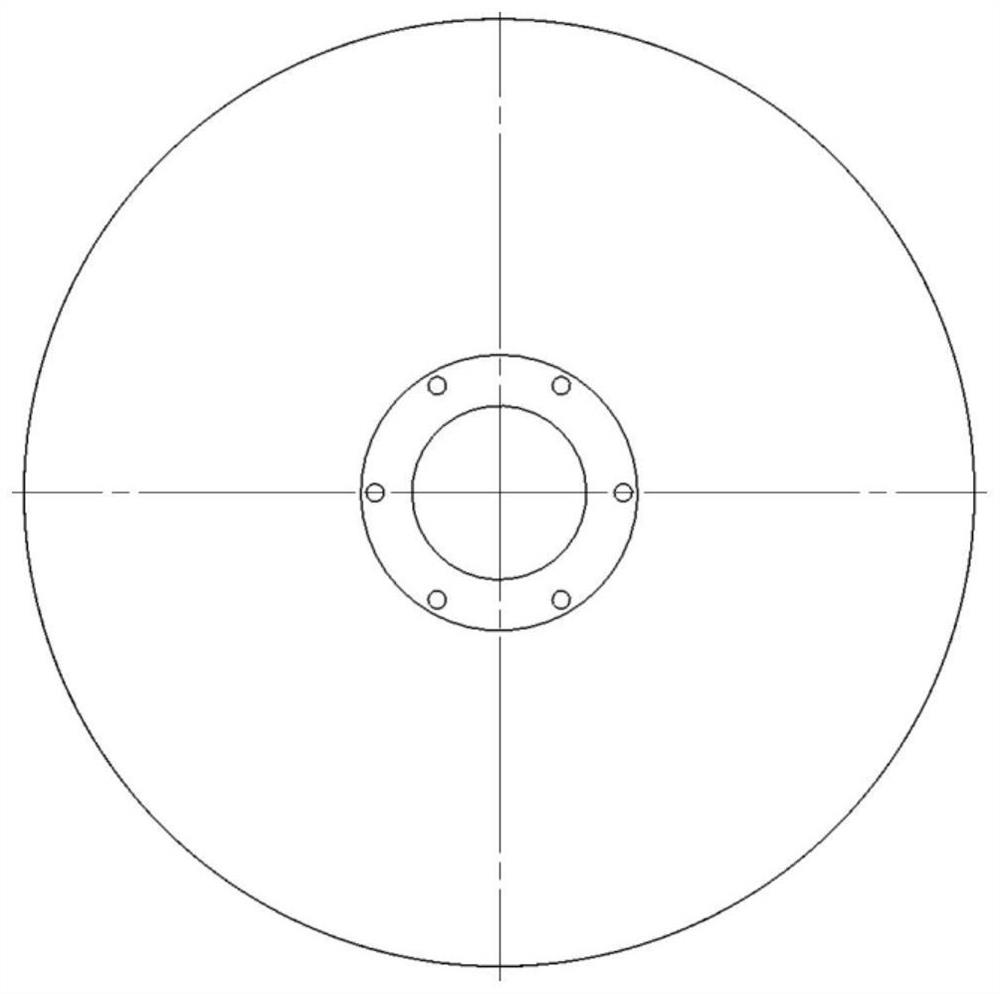

[0019] A reflector 1 is made of silicon carbide, the front is a mirror surface, the thickness is 6mm, the back is a triangular lightweight structure, the thickness of the rib plate is 3mm, and there are 36 installation holes uniformly arranged on the back;

[0020] Mirror B is made of silicon carbide, the front is a mirror surface, the thickness is 6mm, the back is a triangular lightweight structure, the thickness of the rib plate is 3mm, and there are 6 installation holes evenly distributed on the inner circumference, and there is a hollow cavity inside, which is convenient for installing the support structure through;

[0021] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com