Mixer with adjustable discharge hole

A technology of discharge port and mixer, which is applied in the field of discharge structure, can solve the problems of time-consuming and labor-intensive, increased production costs, etc., and achieve the effects of reducing production costs, solving powder blockage, and avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0030] In the present invention, in the absence of a contrary statement, the orientation words included in the term, such as "top, bottom, upper and lower", only represent the orientation of the term in the normal use state, or are understood by those skilled in the art colloquial term and should not be construed as a limitation of the term.

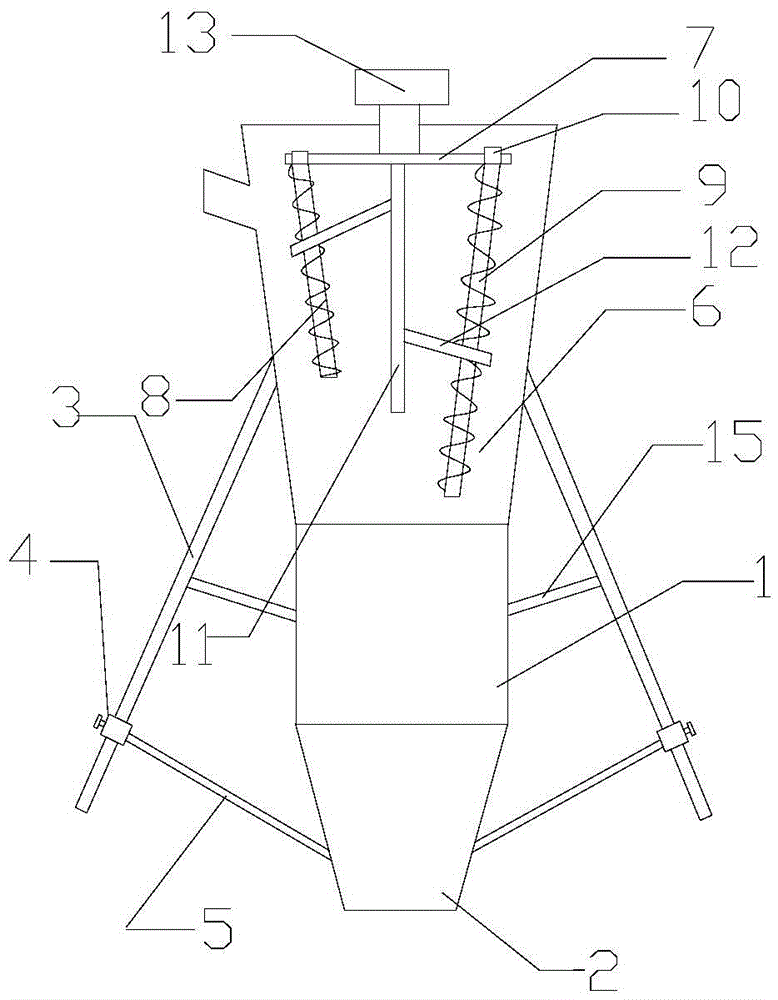

[0031] The invention provides a mixer with an adjustable outlet, such as figure 1 As shown, it includes a mixing cylinder 6, a buffer section 1 and a discharge section 2 connected sequentially from top to bottom. The discharge section 2 is surrounded by a plurality of fixed plates and a plurality of elastic plates. At lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com