Electronic component storage box

A technology of electronic components and storage boxes, applied in the field of storage boxes, can solve problems such as low efficiency, waste of labor, and restricted production capacity, and achieve the effect of large storage quantity, simple structure, and high storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

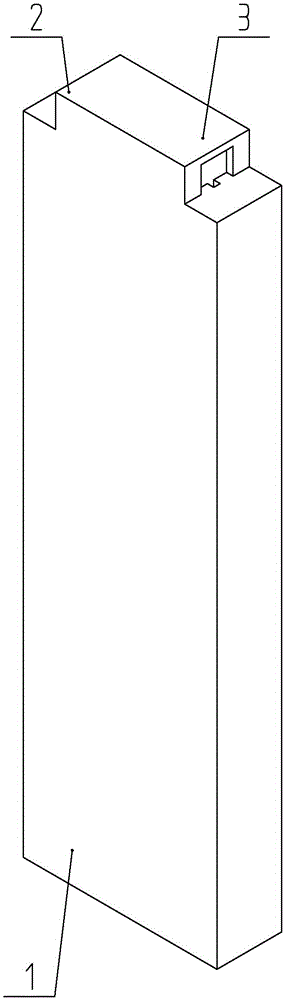

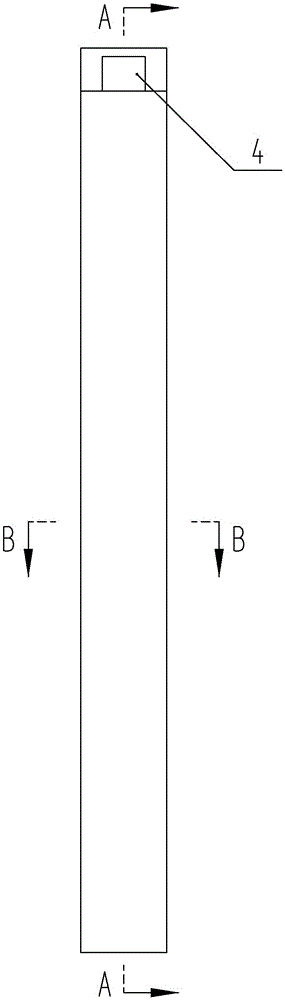

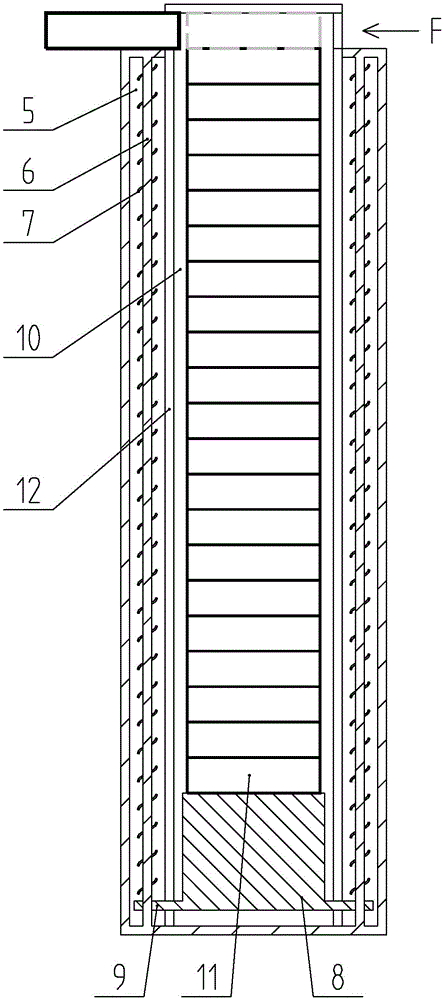

[0018] Such as Figures 1 to 4 As shown, in this embodiment, the so-called height direction refers to the direction where the longer side in the figure is located. The storage box can be used standing up as shown in the picture, or it can be used horizontally. An electronic component storage box includes a casing 1 made of hard plastic injection molding and having an inner cavity. Two side plates 12 parallel to each other are arranged in the shell 1 along the height direction to divide the inner cavity into a storage chamber 10 and two side chambers 5 located on both sides of the storage chamber 10 . A slot extending along the height direction is opened on the side plate 12 , and the slot connects the receiving chamber 10 and the side chamber 5 with each other. The top of the casing 1 is provided with a convex shell 2 , the interior of the convex shell 2 is integrated with the accommodation chamber 10 , and the left and right ends of the convex shell 2 communicate with the o...

Embodiment 2

[0020] Different from Embodiment 1, in this embodiment, the movable baffle 3 is detachably installed on the top of the convex shell 2 through bolts, so as to realize the opening and closing of the top of the convex shell 2 .

[0021] When storing the workpieces 11 , the movable baffle 3 on the top of the convex shell 2 is opened to expose the accommodation chamber 10 , and the workpieces 11 enter the accommodation chamber 10 side by side one by one. As the number of workpieces 11 increases, the lifting platform 8 gradually descends and makes the spring 7 gradually have greater potential energy. When the accommodating chamber 10 has been filled with workpieces 11, it is only necessary to close and lock the movable baffle 3.

[0022] When picking up the piece, a force F aligned with the pick-up opening 4 is applied through the thimble (driven by the cylinder), and the workpiece 11 (the first workpiece 11 ) located at the pick-up opening 4 is pushed out. Under the action of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com