Polypropylene plastic leather shoes box

A polypropylene plastic and leather shoe technology, applied in the field of shoe boxes and leather shoe boxes, can solve problems such as deformation or shoes falling out of the shoe box, poor load-bearing capacity of the shoe box, and weak structure, etc., to reduce wood and chemical raw materials, The effect of high production efficiency and convenient selection of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

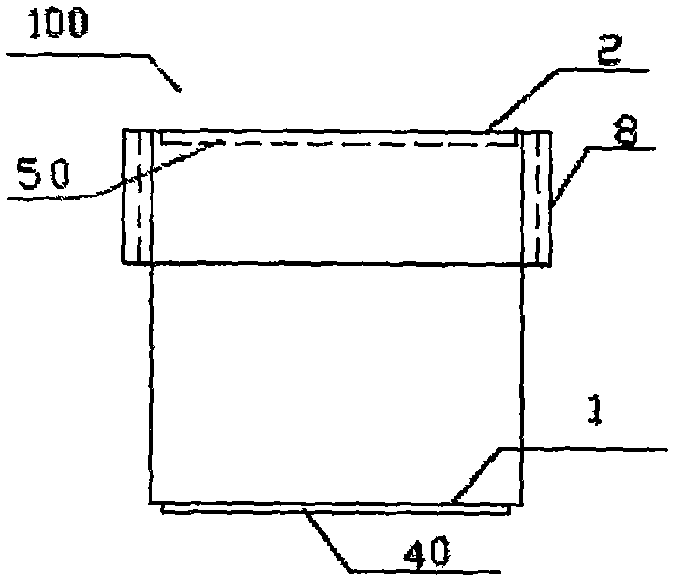

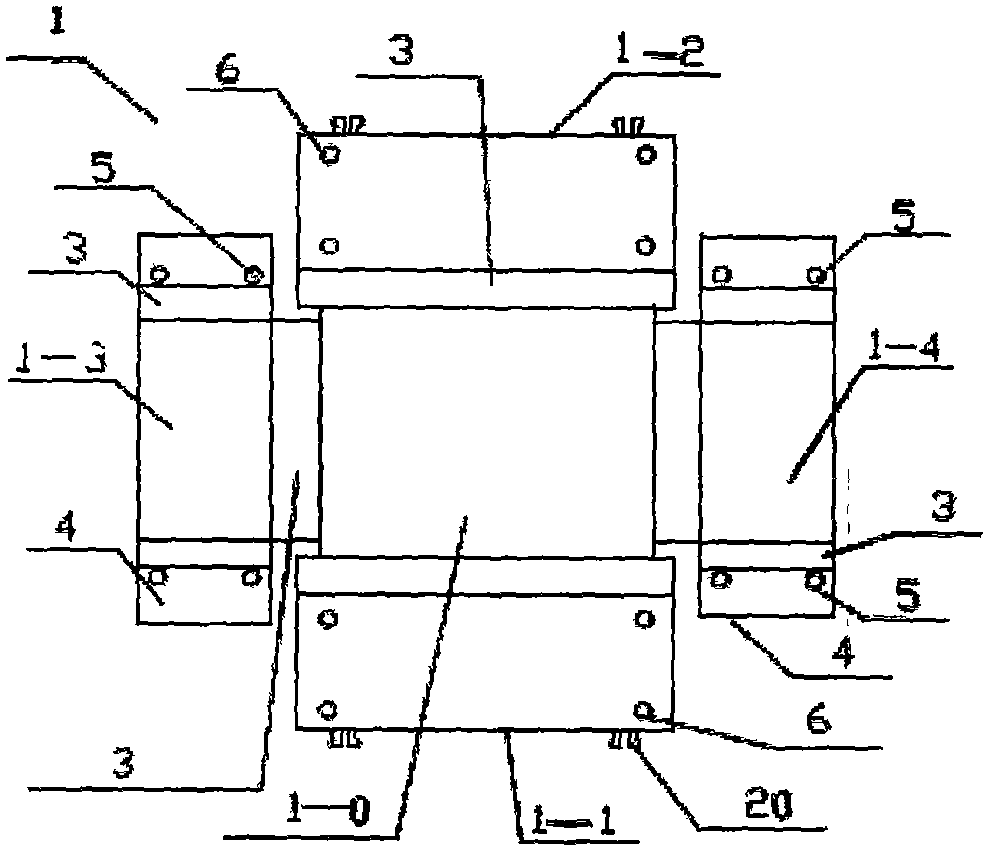

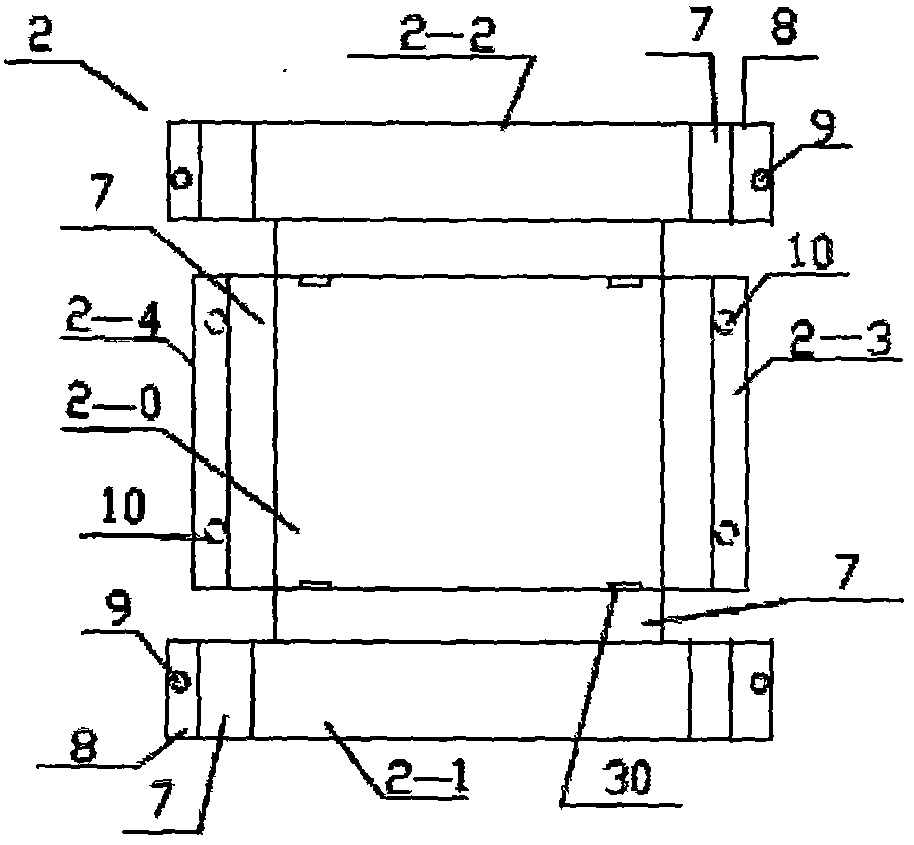

[0011] Such as Figure 1 to Figure 4 As shown, the embodiment of the polypropylene plastic leather shoe box of the present invention, the polypropylene plastic leather shoe box 100 is made of thermoplastic transparent or colored polypropylene plastic through a molding mold in a plastic machine and processed into a flat bottom box 1 part and cover 2 parts. The front, back, left and right sides of the bottom plate 1-0 in the bottom box 1 part are provided with grooves A3 to connect the front box plate 1-1, the rear box plate 1-2, the left box plate 1-3, and the right box plate. Plate 1-4, both sides of the left box plate 1-3 and the right box plate 1-4 are provided with a groove A3 to connect the gusset Y4, and the inner surface of the groove A3 is provided with a slope 00 with a degree of 45 degrees. The gusset Y4 is provided with a locking hole b5. The front box plate 1-1 and the rear box plate 1-2 are provided with a lock a6 corresponding to the buckle Y4 with a lock hole b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com