Compound fuel and preparation method and application thereof

A composite fuel and formulation technology, applied in the fuel and petroleum industries, etc., can solve the problems of accelerating the corrosion of alcohol-based fuels to the engine fuel system, unutilized heat, and increasing fuel consumption, and achieves good water resistance and cold start performance. Excellent cold start performance and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

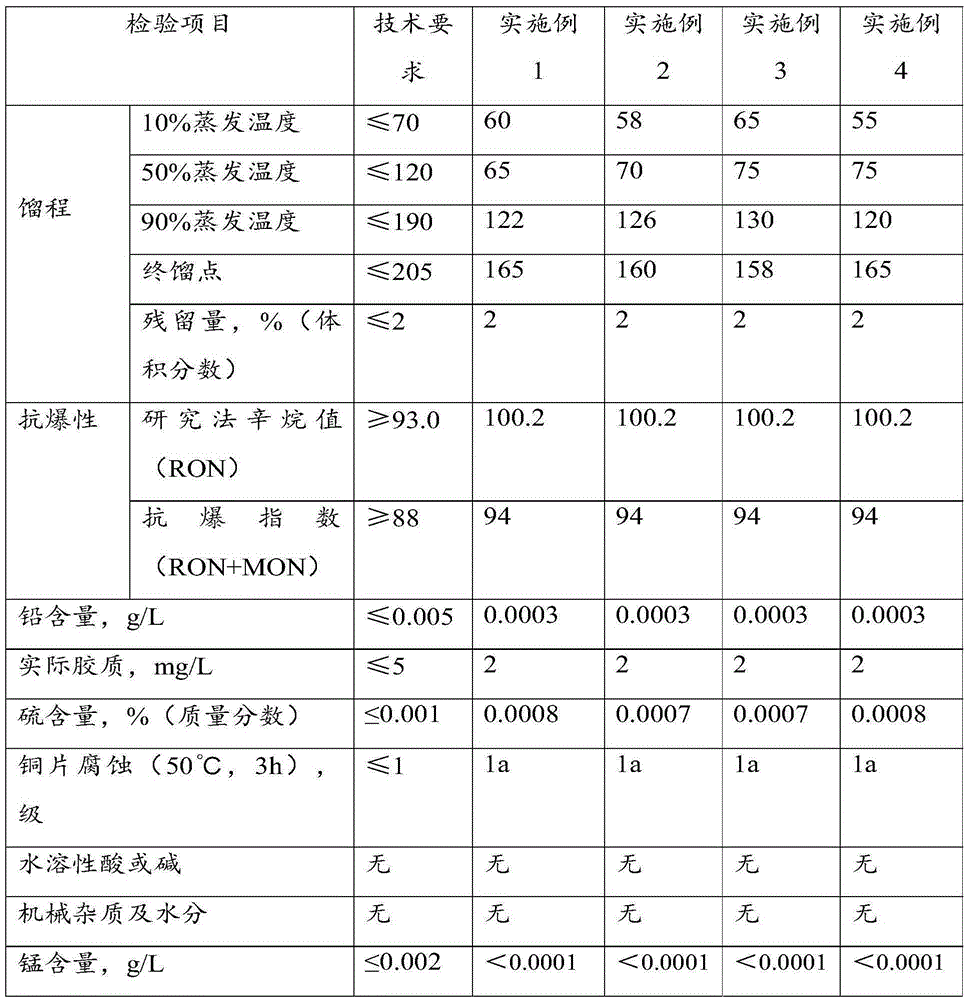

Examples

Embodiment 1

[0041] Follow the steps below to prepare fuel:

[0042] 1. Mix 10 tons of mixed aromatics and 15 tons of coking benzene into the blending kettle 1, and then use an explosion-proof pump to circulate and stir for 20 minutes under normal temperature and pressure conditions, and let it stand for 1 hour to be used as an auxiliary agent;

[0043] 2. Mix 10 tons of methanol and 30 tons of naphtha and put them in the blending kettle 2, add the additives prepared in the blending kettle 1 to the blending kettle 2, use an explosion-proof pump to stir and circulate for 20 minutes, and let it stand for 24 hours to get the finished product.

Embodiment 2

[0045] Follow the steps below to prepare fuel:

[0046] 1. Mix 10 tons of mixed aromatics and 20 tons of coking benzene into the blending kettle 1, then use an explosion-proof pump to circulate and stir for 30 minutes under normal temperature and pressure conditions, and let it stand for 1 hour to be used as an auxiliary agent;

[0047] 2. Mix 40 tons of methanol and 90 tons of naphtha and put them in the blending kettle 2, add the additives prepared in the blending kettle 1 into the blending kettle 2, use an explosion-proof pump to stir and circulate for 60 minutes, and let it stand for 24 hours to get the finished product.

Embodiment 3

[0049] Follow the steps below to prepare fuel:

[0050] 1. Mix 2 tons of mixed aromatics and 1 ton of coking benzene into the blending kettle 1, and then use an explosion-proof pump to circulate and stir for 10 minutes under normal temperature and pressure conditions, and let it stand for 1 hour to be used as an auxiliary agent;

[0051] 2. Mix 2 tons of methanol and 5 tons of naphtha and put them in the blending kettle 2, add the additives prepared in the blending kettle 1 into the blending kettle 2, use the explosion-proof pump to stir and circulate for 30 minutes, and let it stand for 24 hours to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com