Electrophoretic painting clamp for shock absorber

A technology of electrophoretic coating and shock absorber, which is applied in the field of fixtures and fixtures, can solve problems such as poor electrophoretic conductivity of shock absorbers, and achieve the effect of solving poor electrophoretic conductivity and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

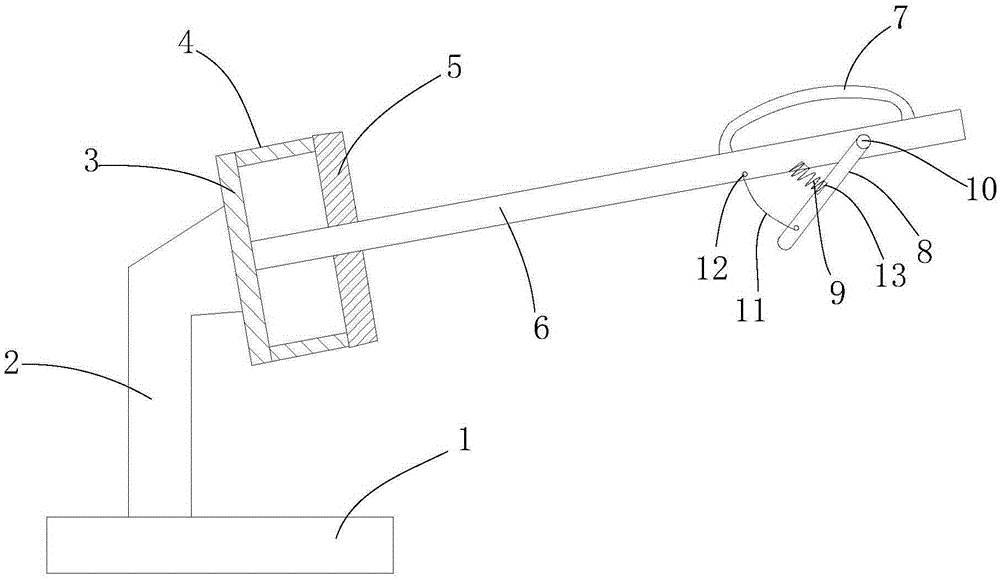

[0036] Such as figure 1 As shown, a shock absorber electrophoretic coating fixture includes a base 1 and a support frame 2 installed on the base 1, a support plate 3 and a sleeve 4 are installed on the support frame 2, and the support plate 3 and the sleeve 4 are both Made of steel, the support plate 3 is fixed with a support rod 6, the casing 4 is located on the periphery of the support rod 6, and the end of the support rod 6 away from the support plate 3 is equipped with a conductive block 8 and an arc-shaped conductive plate 7, the conductive plate 7 Made of steel, the conductive block 8 is a red copper conductive block, the first end of the conductive block 8 is hinged to the support rod 6, the second end of the conductive block 8 is an arc structure, and the conductive block 8 and the support rod 6 are provided with An elastic member that props up the conductive block 8 , and a limiting member that limits the swing range of the conductive block 8 is also provided between ...

Embodiment 2

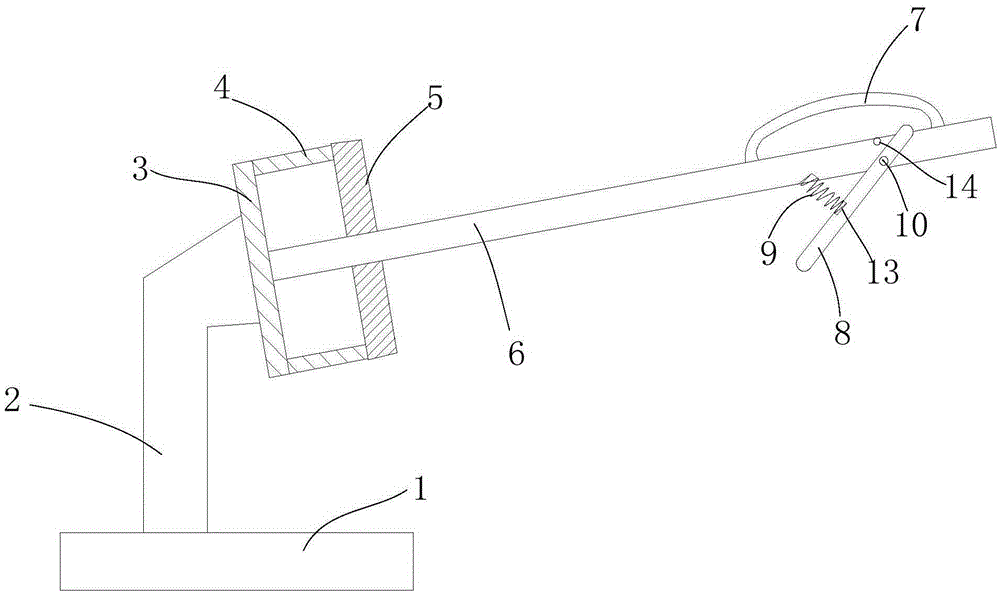

[0041] Such as figure 2 As shown, the difference between this example and Embodiment 1 is that the limiting member is a limiting column 14 arranged on the support rod 6, and the limiting column 14 and the elastic member are located on the same side of the conductive block 8, and the limiting column 14 and the elastic member are respectively located on both sides of the hinge point. When the compression spring 9 is propped up, the first end of the conductive block 8 abuts against the limit post 14 , and its maximum rotation range is limited by the limit post 14 .

[0042] In the present invention, the structure of the conductive block 8 is set, and the conductive block 8 is supported by the elastic member, which can ensure that the conductive block 8 is in contact with the inner wall of the shock absorber when the shock absorber is painted, and avoid poor conduction. Parts work together to limit the swing range of the conductive block 8, so as to avoid contact or too tight co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com