Prestressed pipe pile combined structure

A technology of prestressed pipe piles and composite structures, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as troublesome construction and complicated design of pipe piles, and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

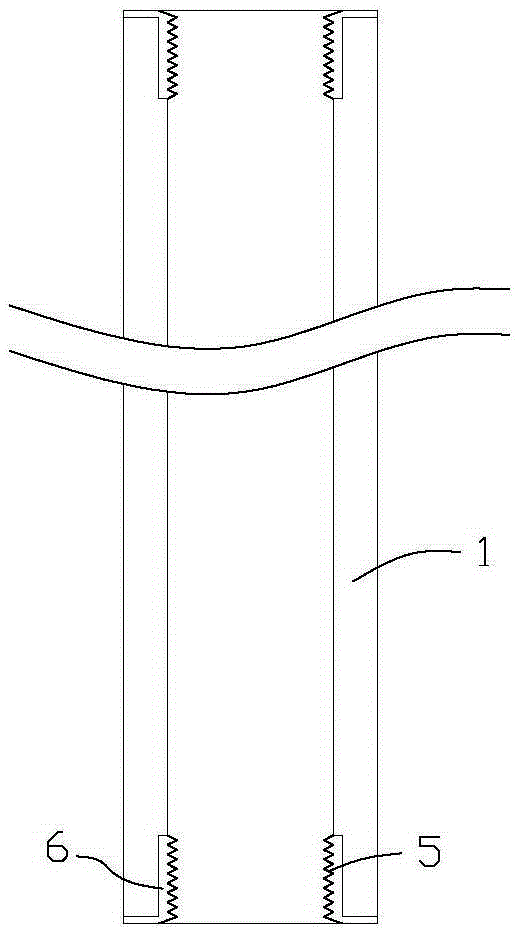

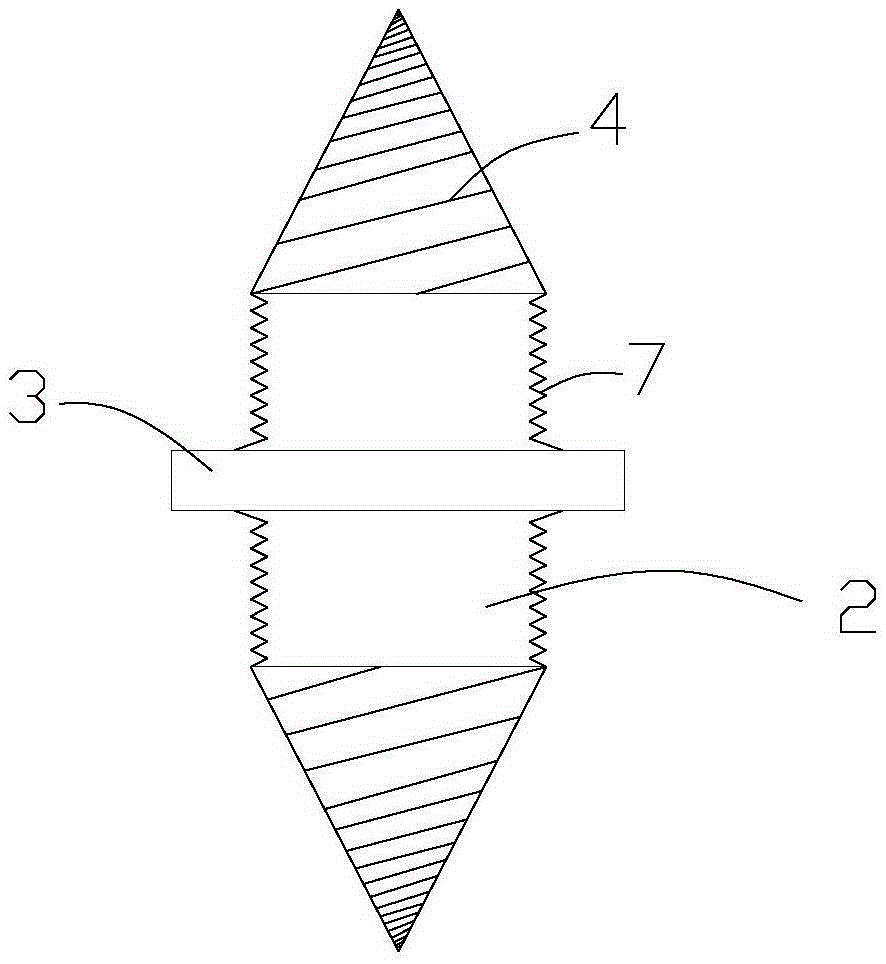

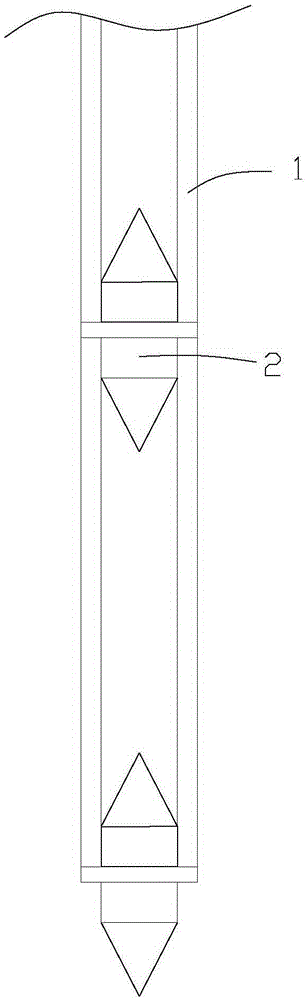

[0016] refer to figure 1 and figure 2 , a prestressed tubular pile composite structure of the present invention includes a pile body 1 and a pile connector 2 . The pile body 1 is hollow cylindrical, and internal threads 5 are provided on the inner walls of both ends of the pile body 1 . Considering that the pile body 1 is made of concrete material, in order to set the internal thread 5 more conveniently, the two ends of the pile body 1 can be fixedly sleeved with a nut 6 with a matching shape. The nut 6 is made of cast iron material, and the internal thread 5 is located on the nut 6.

[0017] The pile connector 2 of the present invention is generally also made of cast iron. The middle part of the pile connector 2 is a cylindrical part, and the outer circumference of the cylindrical part is provided with an external thread 7 matching the internal thread 5 on the inner wall of the pile body 1, and the pile connector 2 can be screwed into the pile body 1 through the external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com