Special small self-priming lock for mini car tail door

A self-priming lock, car technology, applied in vehicle locks, electric locks, building locks, etc., can solve the problems of loosening, high cost, high maintenance cost, and achieve the effects of good reset elasticity, short production cycle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

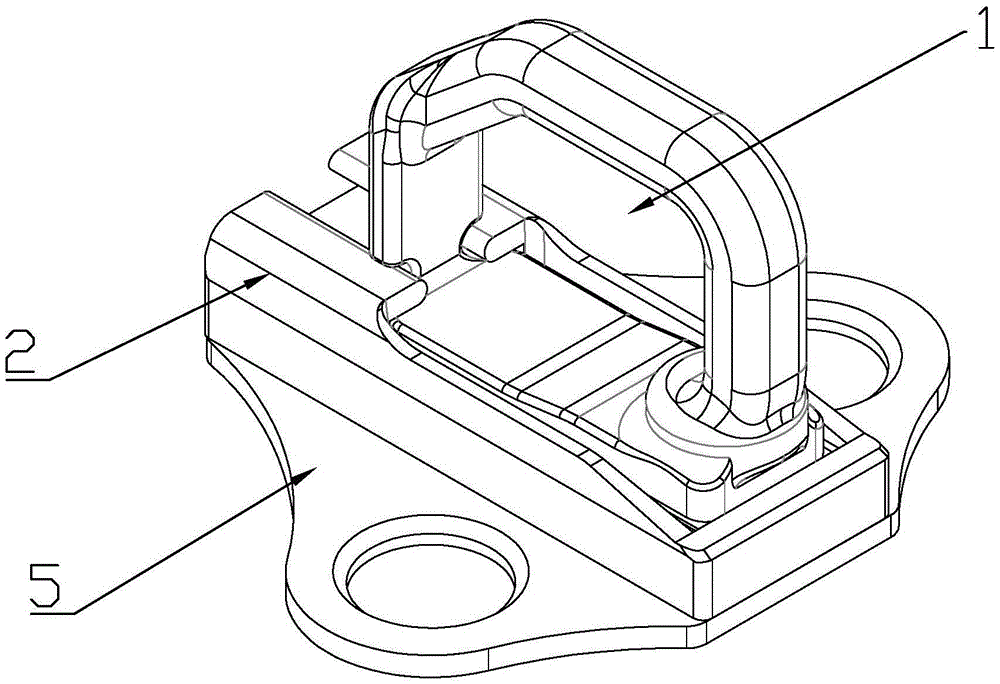

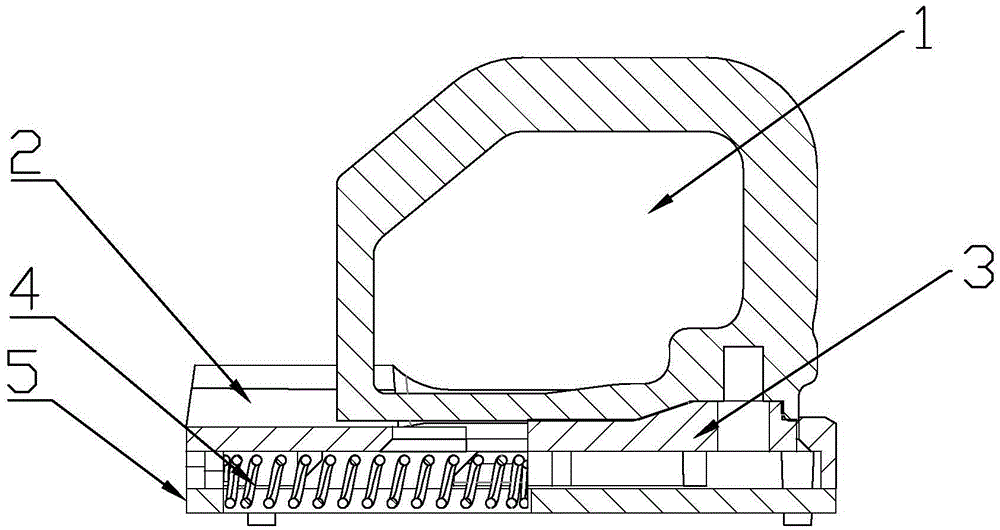

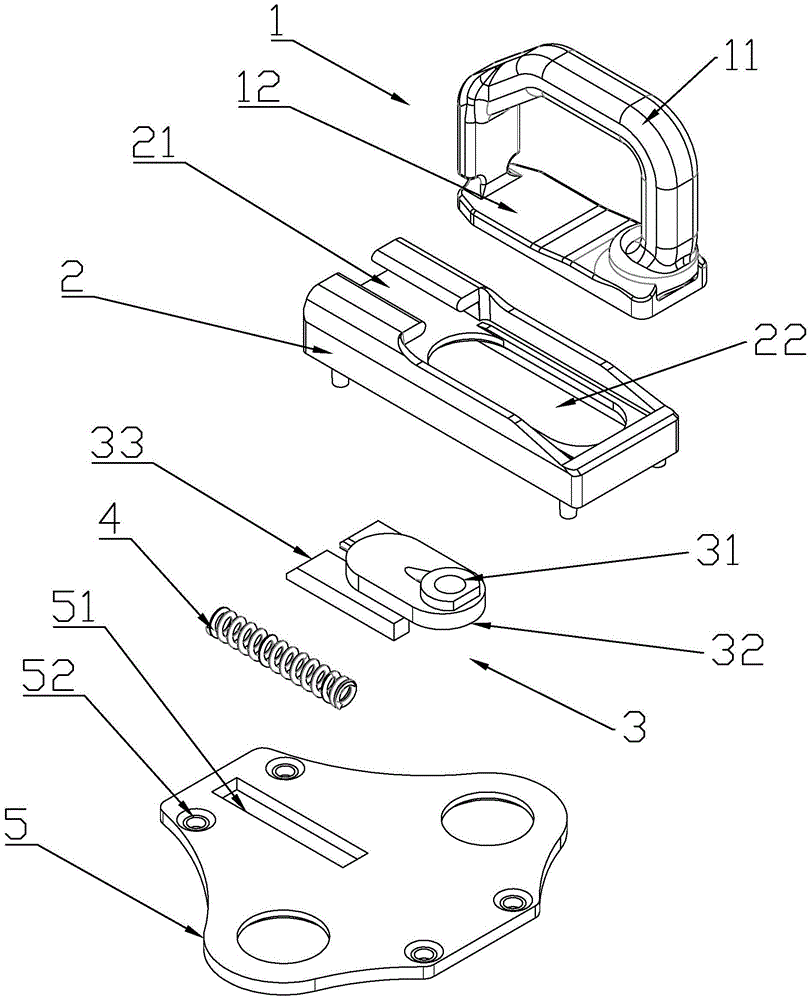

[0012] Such as figure 1 - Figure 4 Shown: a special small self-priming lock for the tailgate of a car, the small self-priming lock includes a lock 1, a fixed seat 2, a slider 3, a return spring 4, and a coupling piece 5; the lock 1 includes a bottom plate 11 and a lock Hook 12, one end on the back of base plate 11 is provided with blind concave hole 101; The front end of the front of described fixed seat 2 is provided with the chute 21 that is used for base plate 11 to slide back and forth after inserting, and the rear end is provided with a strip-shaped through hole 22, and the chute 21 ends The opposite side is provided with a gap 23 through which the wire rope passes, and the four corners of the entire fixed seat 2 are extended with fixed columns 24; The sliding limiter 32 of the shaped through hole 22, the sliding limiter 32 can only slide forward and backward in the elongated through hole 22, and the bottom two sides of the sliding limiter 32 each extend a sliding plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com