Process of full-mechanized caving mining of multi-port as well as coal drawing

A kind of process and fully mechanized caving technology, which is applied in the field of multi-hole coal caving technology in fully mechanized caving mining, which can solve the problems of low top-coal recovery rate, unsuitable for high-efficiency and high-recovery development of coal resources, and top-coal loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

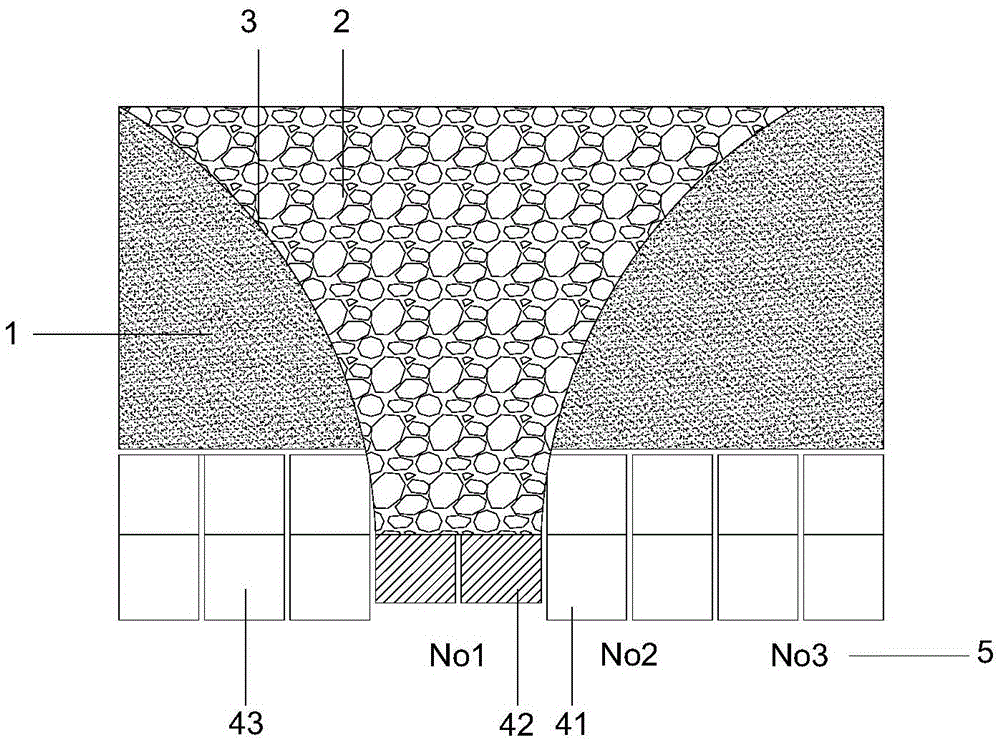

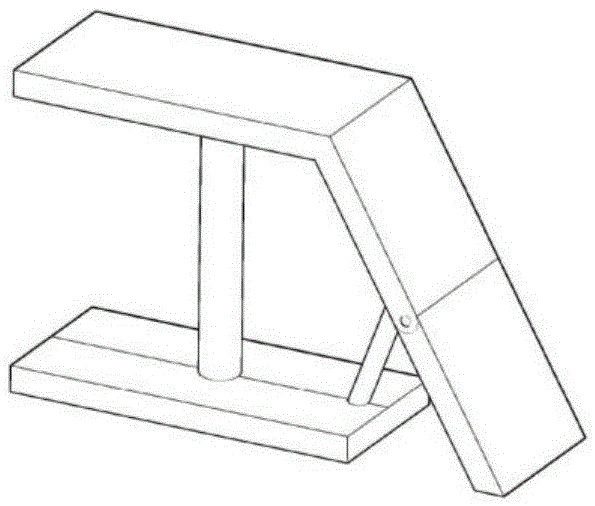

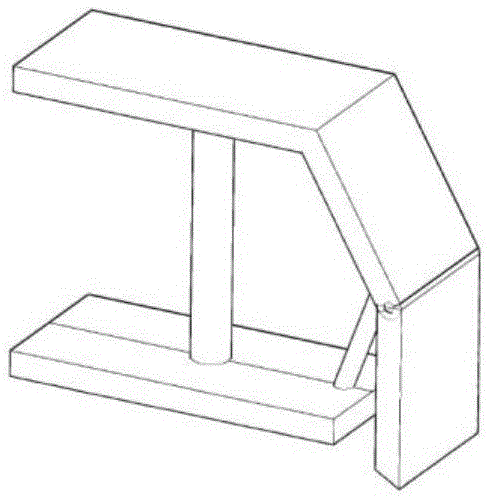

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] In a fully mechanized coal caving mining multi-hole simultaneous coal discharge process, it mainly includes the optimization and improvement of three aspects: the coal discharge method, the roof management method and the parameters of supporting equipment: the coal discharge method is to open multiple Coal discharge operation is carried out at the coal discharge port of the adjacent support; the roof management method is to move the support in groups in time after each support sees the gangue and closes the door; the supporting equipment parameters include the traction speed of the coal cutter and the transportation of the scraper conveyor. Capacity, speed of the scraper chain.

[0024] In a fully mechanized coal caving mining multi-hole simultaneous coal caving process, the specific operation of the coal cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com