Dynamic PID (proportional integral derivative) control based hydroviscous variable speed clutch control method

A clutch control and clutch technology, applied in clutches, fluid clutches, mechanical equipment, etc., can solve the problems of poor dynamic response, long adjustment time, and easy vibration, etc., and achieve the effect of reducing vibration, reducing vibration, and avoiding overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

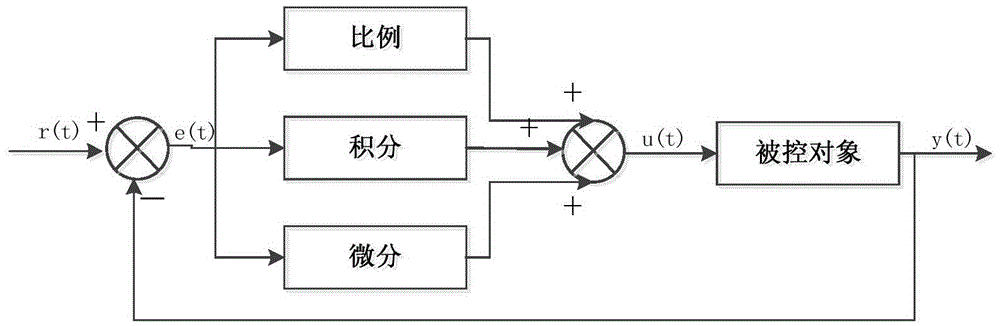

[0024] The block diagram of a conventional PID control system is as follows: figure 2 shown. The control system is composed of PID controller and controlled object. Among them, r(t) is the given value, y(t) is the feedback value of the system, and the given value and the feedback value constitute the control deviation e(t)=r(t)-y(t); e(t) is used as PID The input of the controller, u(t) is used as the output of the PID controller and the input of the controlled object, so the control law of the PID controller is:

[0025] u ( t ) = K P · e ( t ) + K I Σ j = 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com