Self-pressure test gasket and application method thereof

A pressure test and gasket technology, which is used in the use of liquid/vacuum for liquid tightness measurement, fluid tightness test, and machine/structural component testing. It can solve the requirements of high sealing performance and pressure test accuracy. It is not high, the work intensity of workers is high, etc., to achieve the effects of accurate detection, convenient and fast installation, and reduced pressure test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

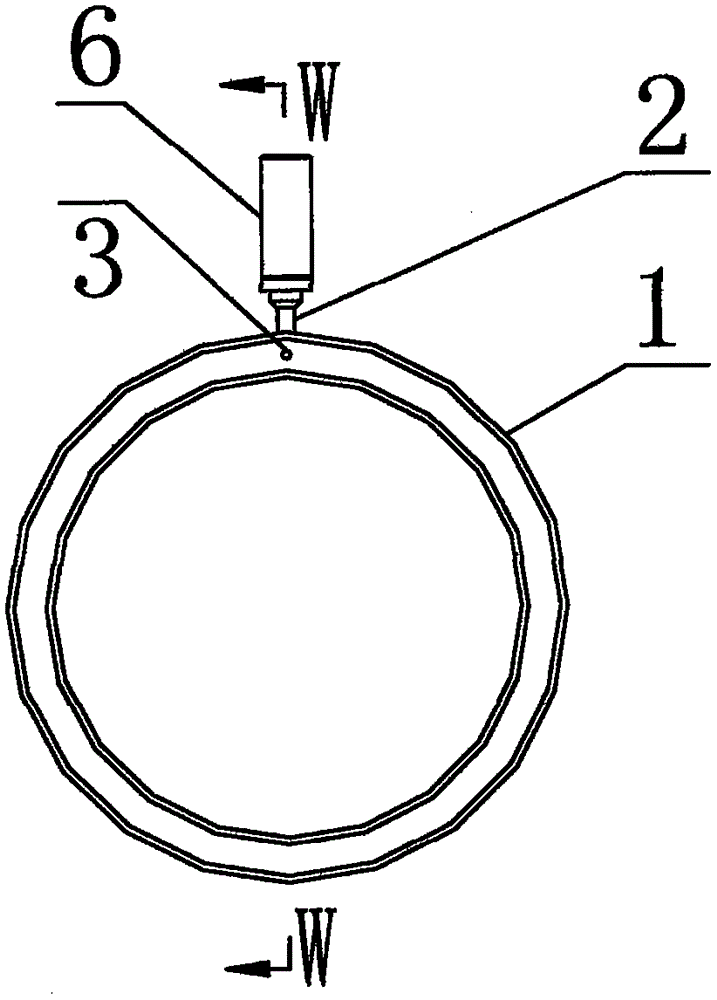

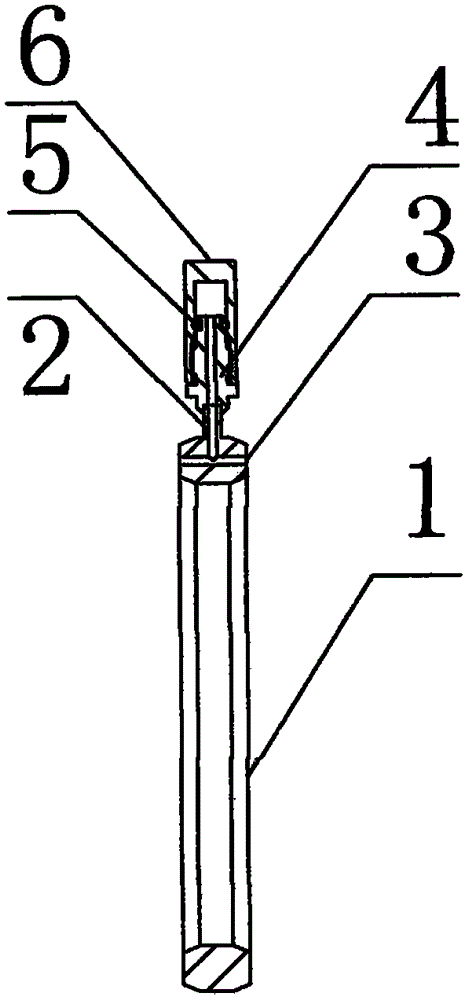

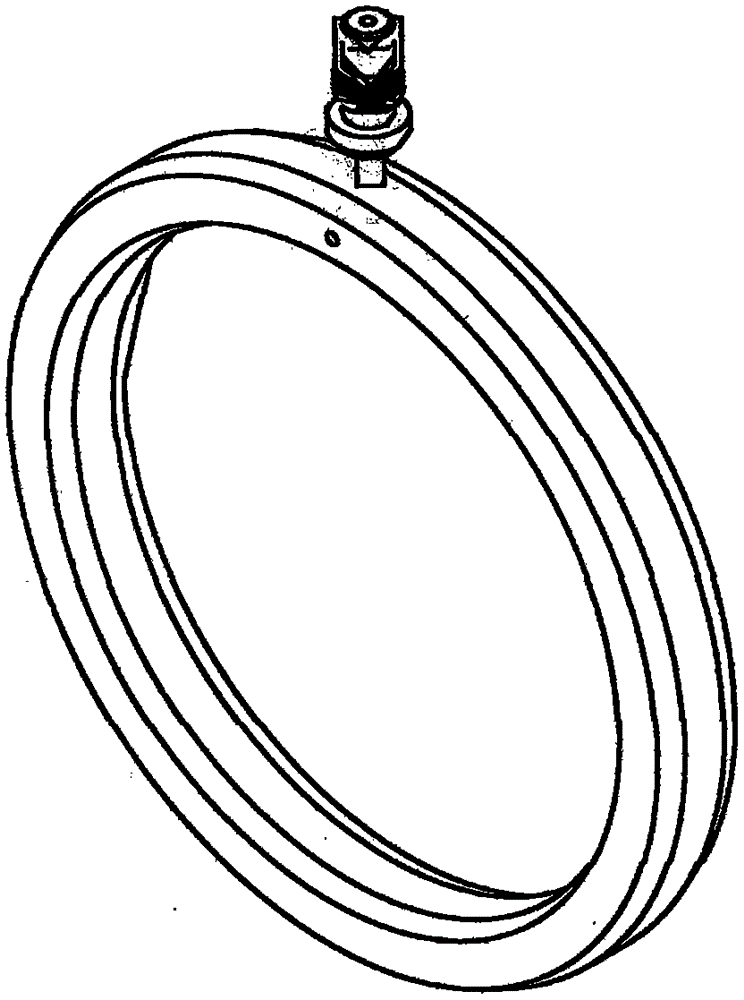

[0025] Attached below Figure 1-4 The structure and application method of the self-test pressure gasket of the present invention are described in detail.

[0026] A self-test pressure gasket, the self-test pressure gasket includes a gasket body 1 and a pressure test assembly arranged on the gasket body; the pressure test assembly includes a pressure test tube 2, a pressure test hole 3, a pressure test pipe joint 4; Wherein, the pressure test hole is at least one through hole arranged on the gasket body; the pressure test tube is arranged on the outer edge of the gasket body, and one end of the pressure test tube is connected to the pressure test hole, and the other end is connected to the pressure test hole. Pipe joints are connected. The pressure test assembly also includes a tee assembly, a pressure gauge and a pressure pump; the pressure test pipe joint, the pressure gauge and the pressure pump are respectively connected to the interface of the tee assembly. A sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com