An air-controlled gas pressure reducer

A pressure reducer and air control technology, applied in the direction of the valve's fluid energy absorption device, valve housing structure, valve operation/release device, etc., to achieve high reliability of mechanical properties, smooth gas flow, and easy inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

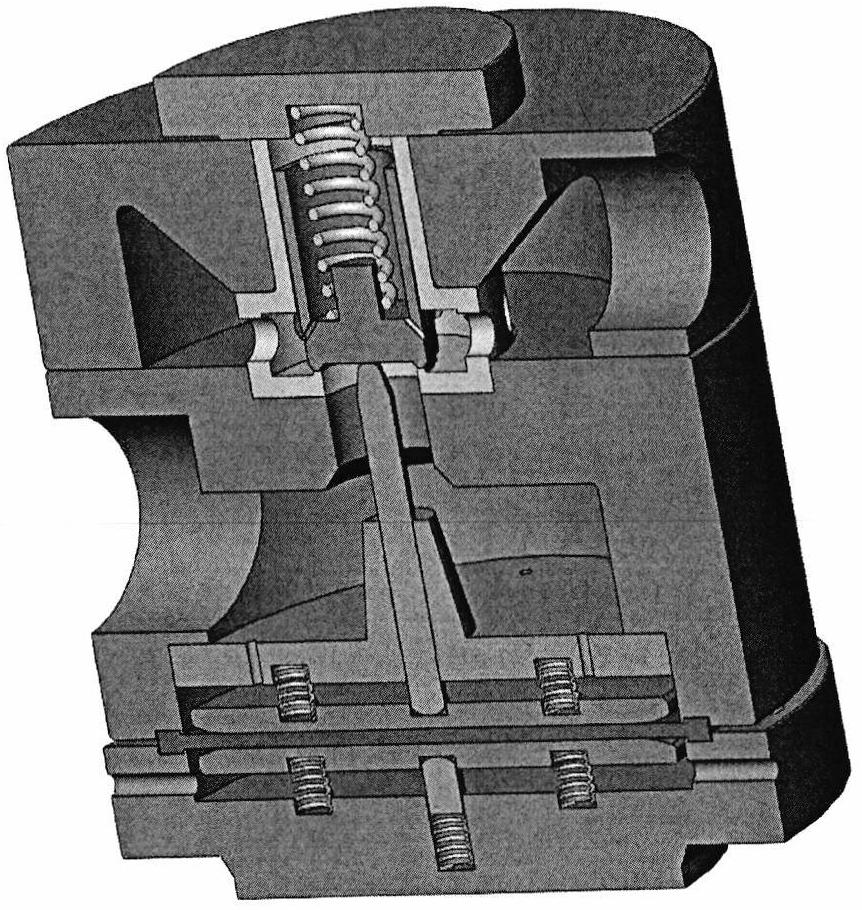

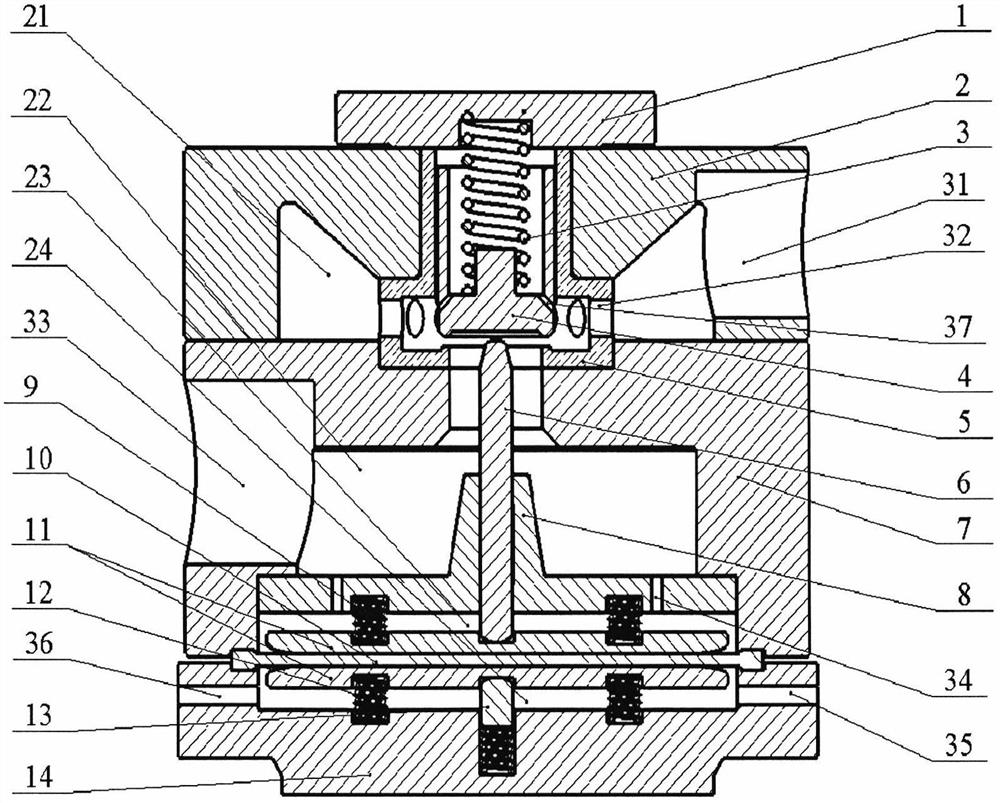

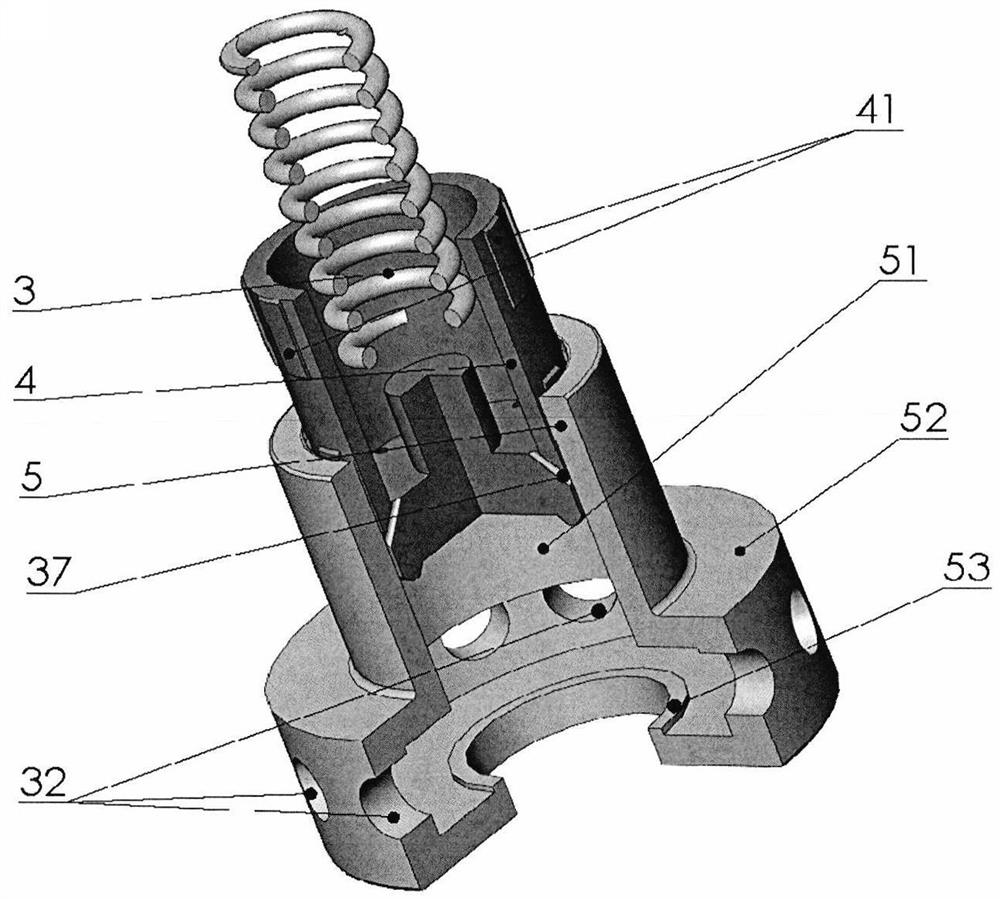

[0040] The specific structure of the pressure reducer of the present invention will be described below in conjunction with the accompanying drawings.

[0041] Such as Figure 1A , 1B As shown, the gas pressure reducer of the present invention has the structural characteristics of "two pieces, three bodies and four cavities", and specifically includes an input cavity 21, an output cavity 22, a damping cavity 23 and a control cavity 24; the upper valve body 2, the middle valve body 7 and the Lower valve body 14; sensing assembly and throttling assembly.

[0042]The input chamber 21 is an annular cavity surrounded by the upper valve body 2, the middle valve body 7 located on the bottom surface of the chamber and the throttling assembly located in the center of the chamber. The upper valve body 2 is a cylinder with a hole in the middle as a whole, made of metal materials such as high-strength stainless steel, and an annular chamber with an "M" cross-section is processed inside, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com