Power supply bin wiring structure for maintaining LED lamp rapidly

A technology of LED lamps and wiring structure, applied in the direction of light source, circuit layout, components of lighting devices, etc., can solve the problems of unsatisfactory secondary installation effect, waste of manpower and material resources, and complicated maintenance operations, so as to avoid the reduction of sealing effect. , saving manpower, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

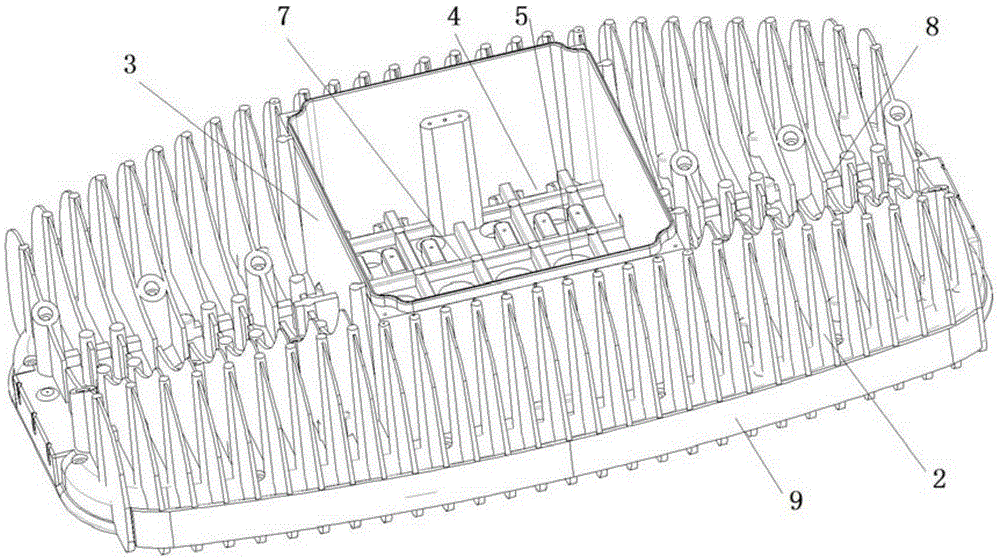

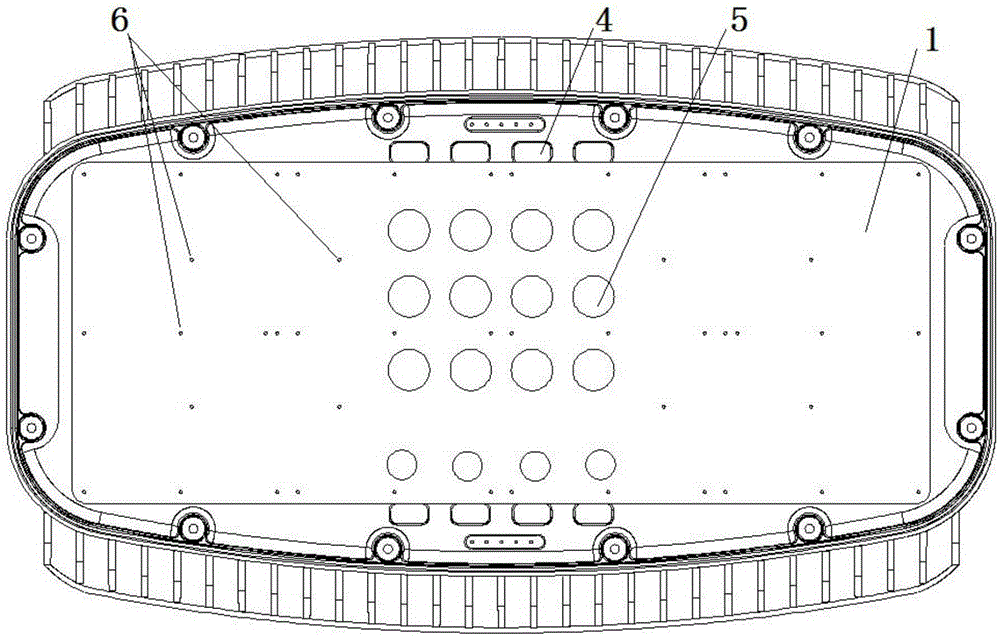

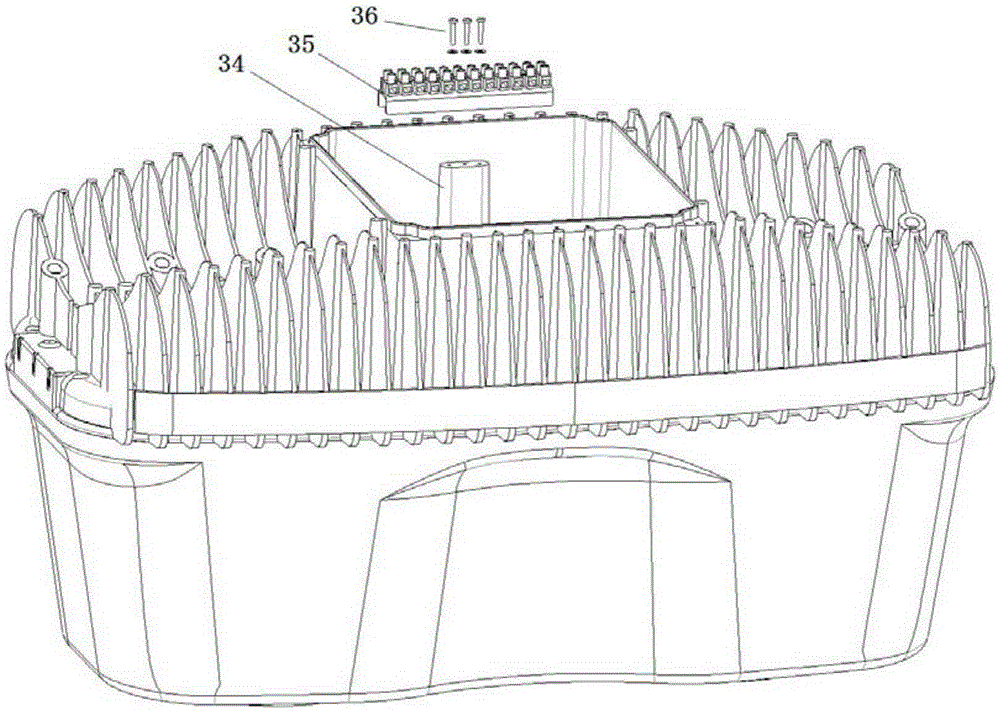

[0034] Such as Figure 1 to Figure 3 As shown, a flat-plate mounting structure is arranged on the front of the heat dissipation housing, and one or more LED chip mounting substrates are fixedly arranged on the front of the mounting structure, the power supply compartment is located on the back of the mounting structure, and the periphery of the power supply compartment is distributed There are multiple rows of heat dissipation fins; the projection positions of the power supply compartment and the LED chip mounting substrate on the mounting structure are staggered from each other, and a wiring hole is opened through the bottom of the power supply compartment, and the lines on the LED chip mounting substrate pass through the wiring holes Introduce the power supply compartment; in the power supply compartment, there is a fixed column near the side wall of the power supply compartment, and a terminal board is arranged on the upper end of the fixed column. There are several terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com