Coupling fiber grating wide-range intelligent carbon fiber rib and manufacturing method thereof

A fiber grating and manufacturing method technology, applied in the field of monitoring, can solve problems such as range limitation, and achieve the effects of expanding the range, improving accuracy and persuasion, and improving the degree of structural adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

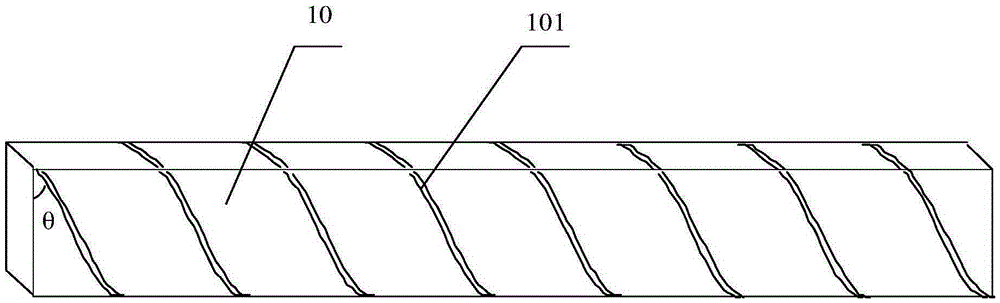

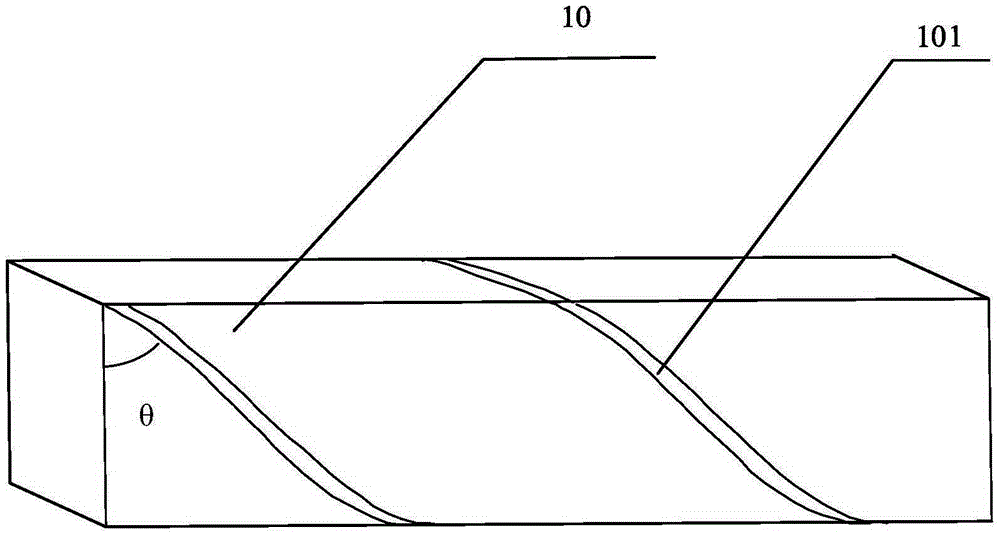

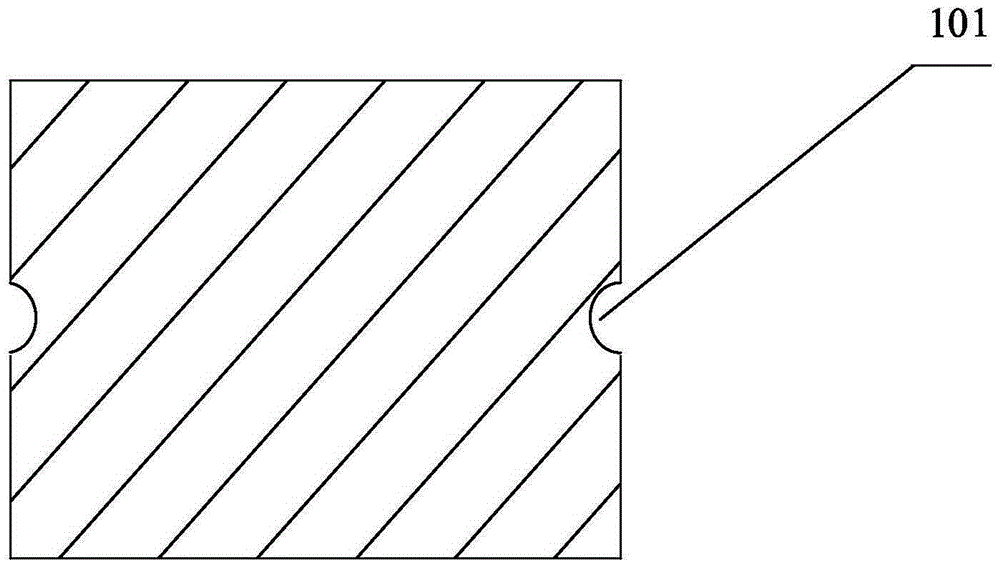

[0032] Such as Figure 1 to Figure 5 As shown, this embodiment provides a large-range smart carbon fiber bar (hereinafter referred to as "carbon fiber bar") 10 coupled with a fiber grating, which is provided with at least one spiral groove 101, and an optical fiber is placed in the spiral groove 101. A wire 102 and an optical fiber protective layer 103 for covering the optical fiber wire 102, and a plurality of strain gratings and temperature gratings are engraved on the optical fiber wire 102.

[0033] Specifically, the carbon fiber reinforcement 10 is a reinforced carbon fiber reinforcement, and its size and specifications can be cut or processed according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com