A positioning method for the manufacture of casing support plate

A positioning method and support plate technology, applied in the field of casting, can solve the problems of inaccurate positioning, wrong teeth of the support plate, etc., and achieve the effects of high positioning accuracy, convenient processing, and meeting design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

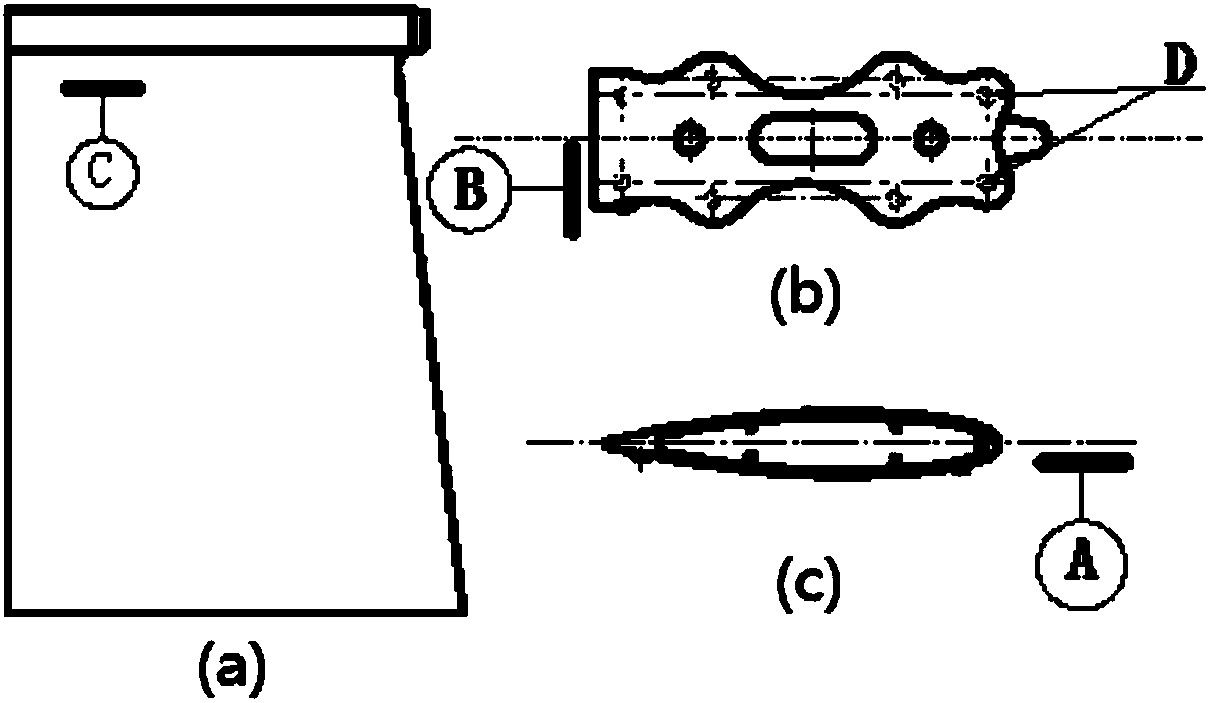

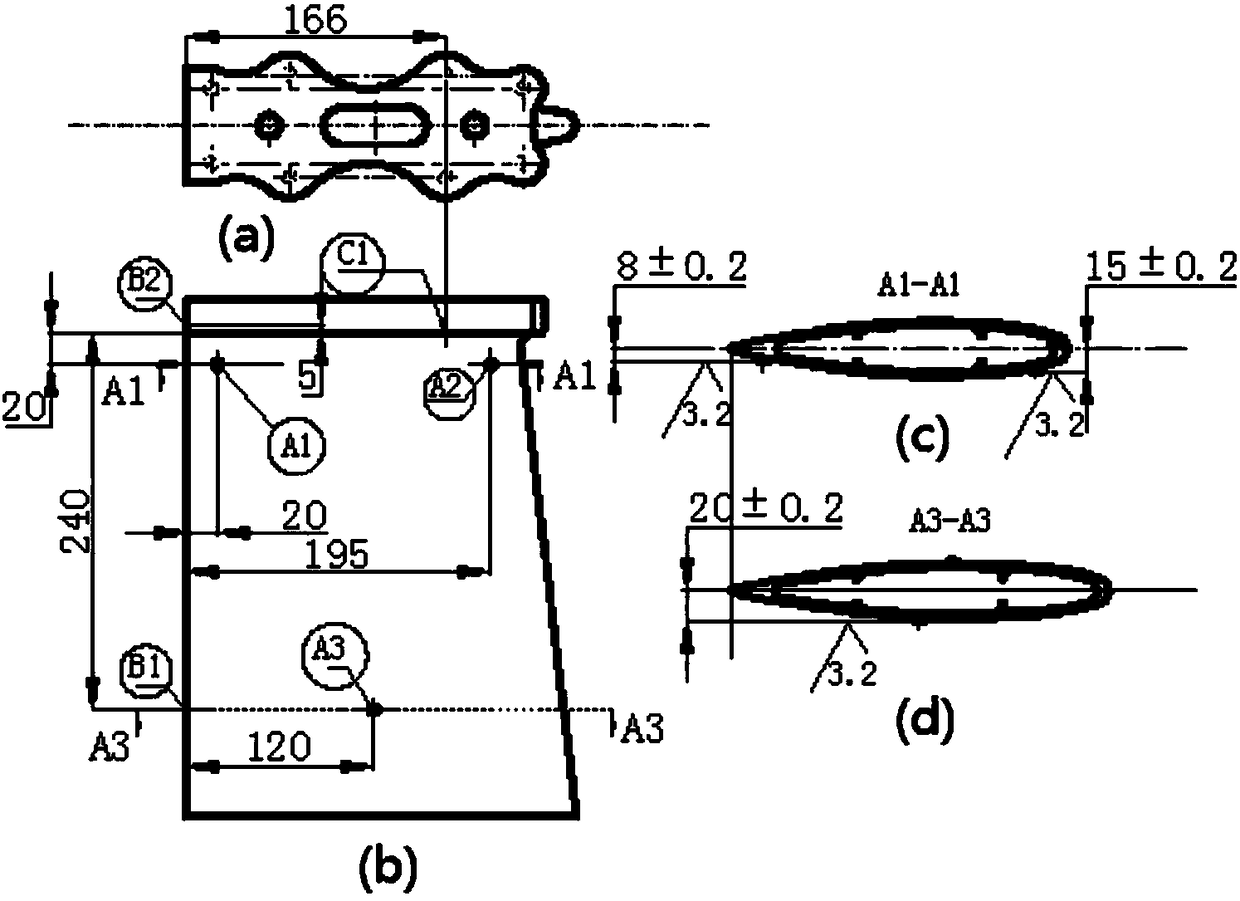

Image

Examples

Embodiment

[0028] In this embodiment, the main steps of manufacturing the casing support plate are as follows:

[0029] 1) Determination of dedicated positioning structure

[0030] According to the dimensional and structural characteristics of the 6 part numbers of the casing support plate, the size requirements of the positioning boss are specified, and the special positioning drawings for the casing support plate are drawn. Optimize the casting mold according to the drawing, and put the casting into production.

[0031] 2) Design and manufacture of special tooling

[0032] The special positioning method for the casing support plate is adopted, and the special tooling is designed and manufactured, which is used for the size inspection of the casing support plate, machining, and welding assembly processes to ensure that the above processes adopt a unified standard.

[0033] 3) Use the effect verification

[0034] Use special tooling to detect, process, and weld the support plate to ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com