Cryogenic Gasket Leakage Test Device

A test device and ultra-low temperature technology, applied in the direction of measurement device, measurement of flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as effective solution of impact problems, lack of valve testing capability of the whole machine, excessive leakage of parts and other problems , to achieve the effect of reasonable structure, simple and reliable measurement, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

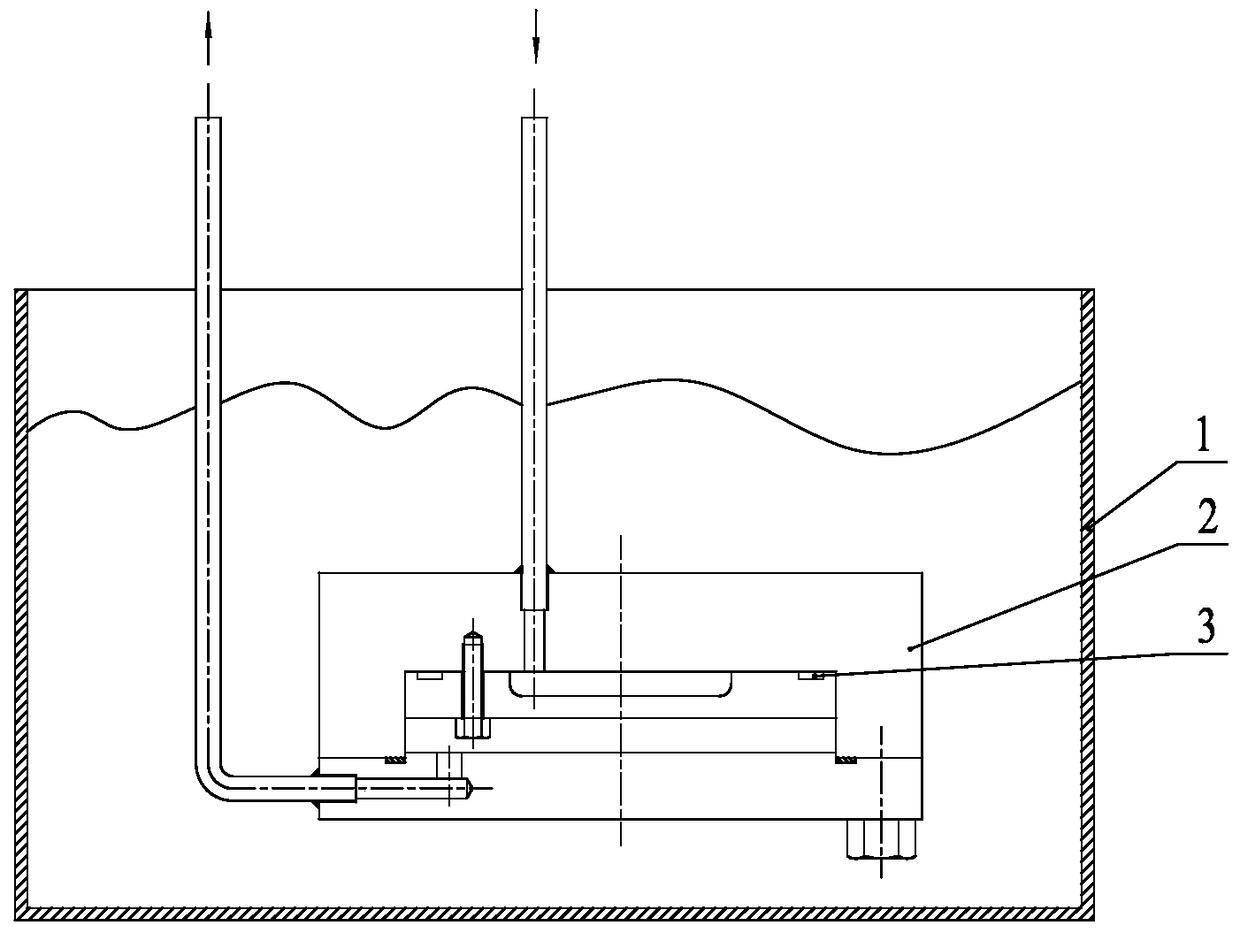

[0012] Such as figure 1 As shown, the ultra-low temperature gasket leakage test device in the embodiment is mainly composed of an incubator 1 and a sealing cylinder 2. The incubator 1 is equipped with a low-temperature cooling medium for forming an ultra-low temperature environment; the sealing cylinder 2 is used for loading After measuring the gasket 3, place it in the incubator 1.

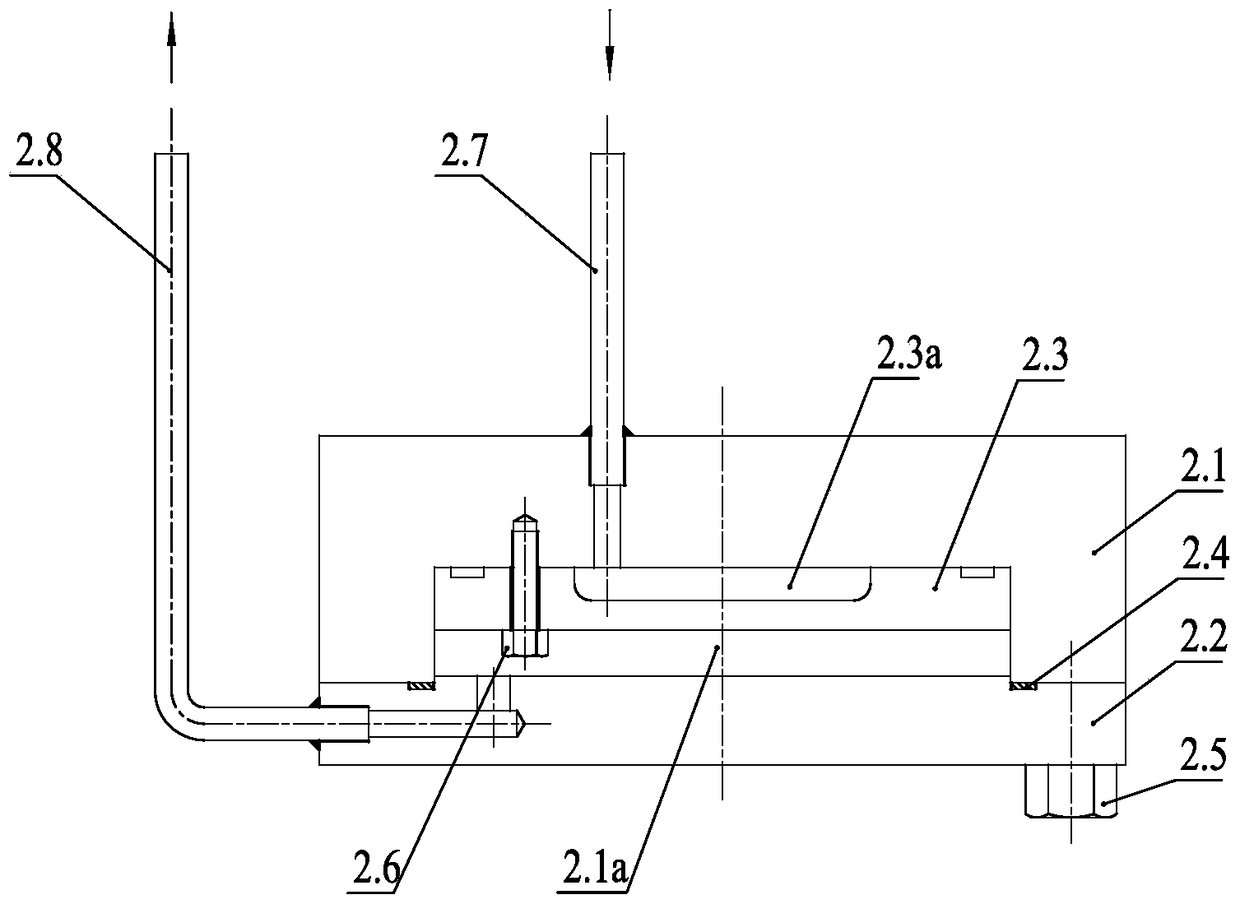

[0013] In the embodiment of the present invention, the detailed structure of the sealed cylinder 2 is as follows figure 2 As shown, it is mainly composed of a cylinder body 2.1, a cylinder end cover 2.2, a sealing seat 2.3, a winding pad 2.4, a first bolt 2.5, a second bolt 2.6, a first air pipe 2.7 and a second air pipe 2.8. The bottom of the cylinder body 2.1 A concave cavity 2.1a is provided, and the cylinder end cover 2.2 is sealed and fastened with the sealed cylinder body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com