Self-calibration optical axis parallelism detector and detection method

A detector and parallelism technology, which is applied in the multi-optical system self-calibration optical axis parallelism detector and detection field, can solve the problems that there is no calibration reference and the parallelism of the beam is difficult to guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

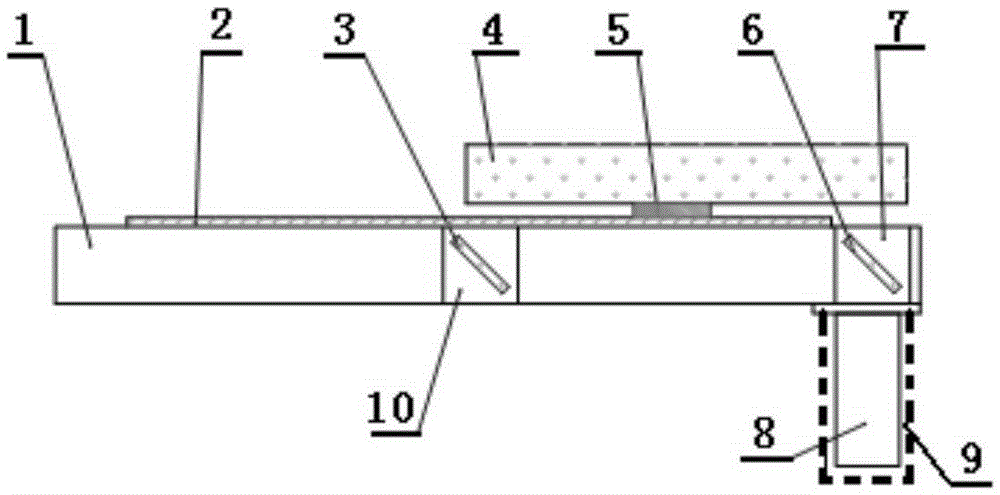

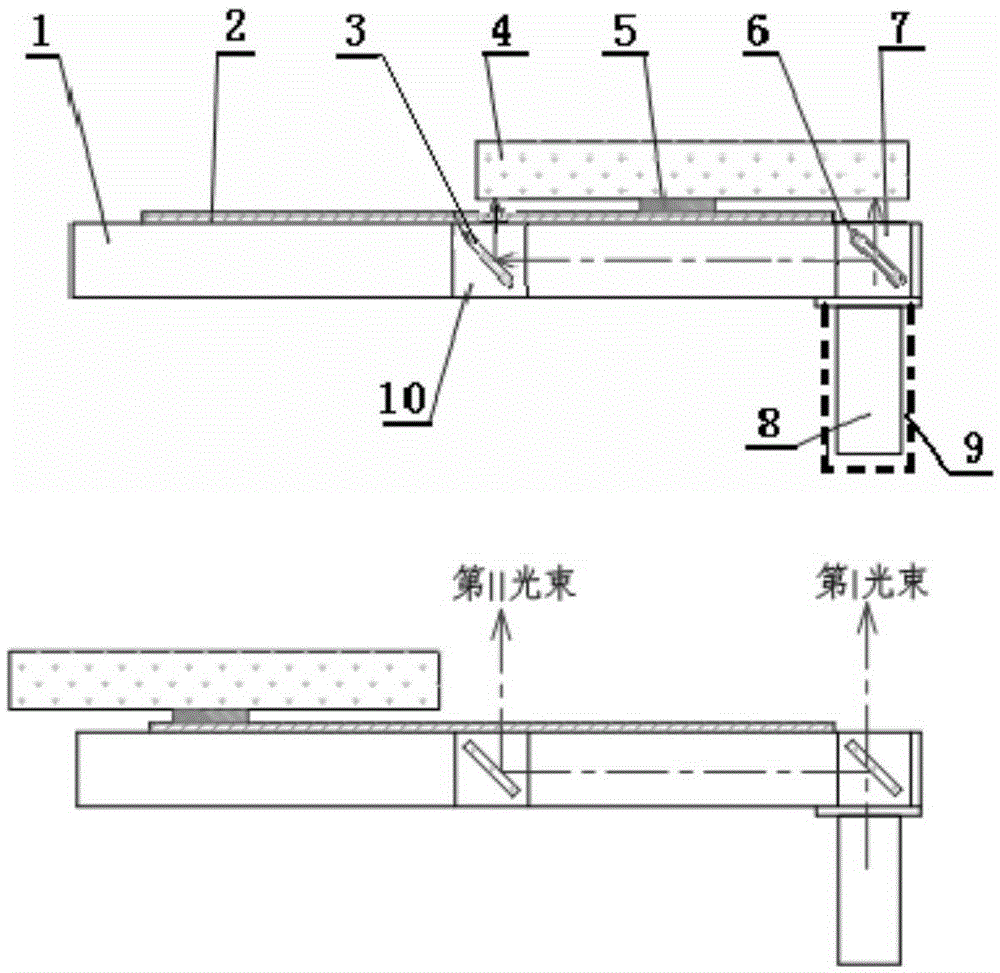

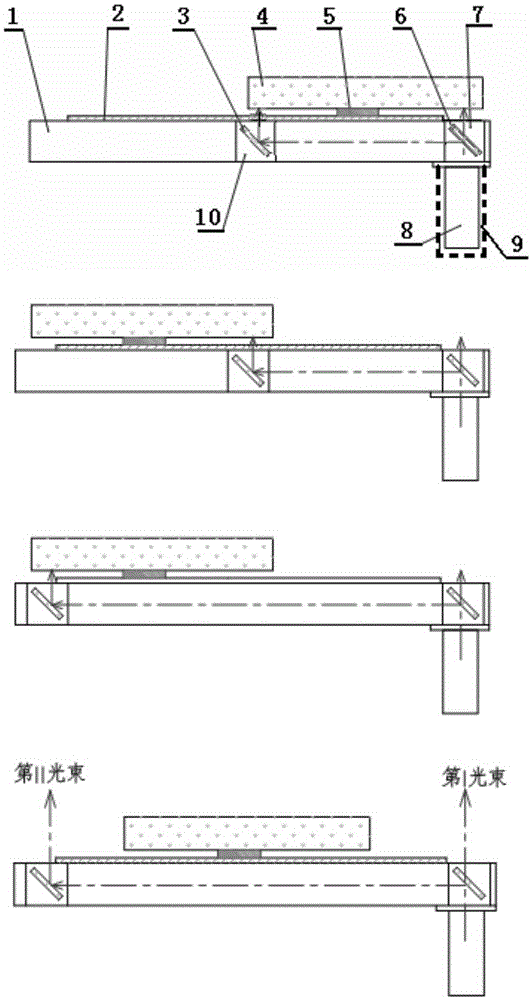

[0018] Such as figure 1 As shown, the self-calibrating optical axis parallelism detector includes: main support guide rail 1, moving guide rail 2, plane deflection mirror 3, flat ruler mirror 4, two-dimensional adjustment mechanism for flat ruler mirror 5, half Anti-transflective plane mirror 6, transflective plane mirror slider 7, autocollimator 8, replaceable reflective collimator 9 and plane deflection mirror slider 10; transflective plane mirror 6 and plane deflection reflection The mirror 3 is installed on the upper surface of the main support rail 1, and can slide arbitrarily on the main support rail 1 through the semi-reflective and semi-transparent plane mirror slider 7 and the plane deflection mirror slider 10, forming an angle of 45 degrees with the main axis of the main support rail 1 ; The moving guide rail 2 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com