Mould for manufacturing three-dimensional compound rock stratum circular tunnel and using method thereof

A three-dimensional composite and rock formation technology, applied in the preparation of test samples, etc., can solve problems such as composite rock formations that can only consider 0° inclination, achieve good production effects, improve experimental accuracy, reduce experimental difficulty and experimental errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

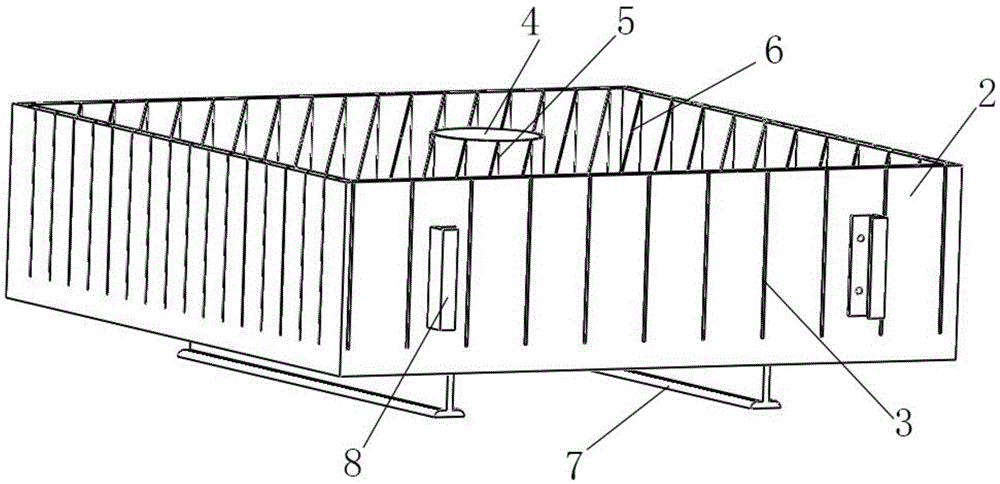

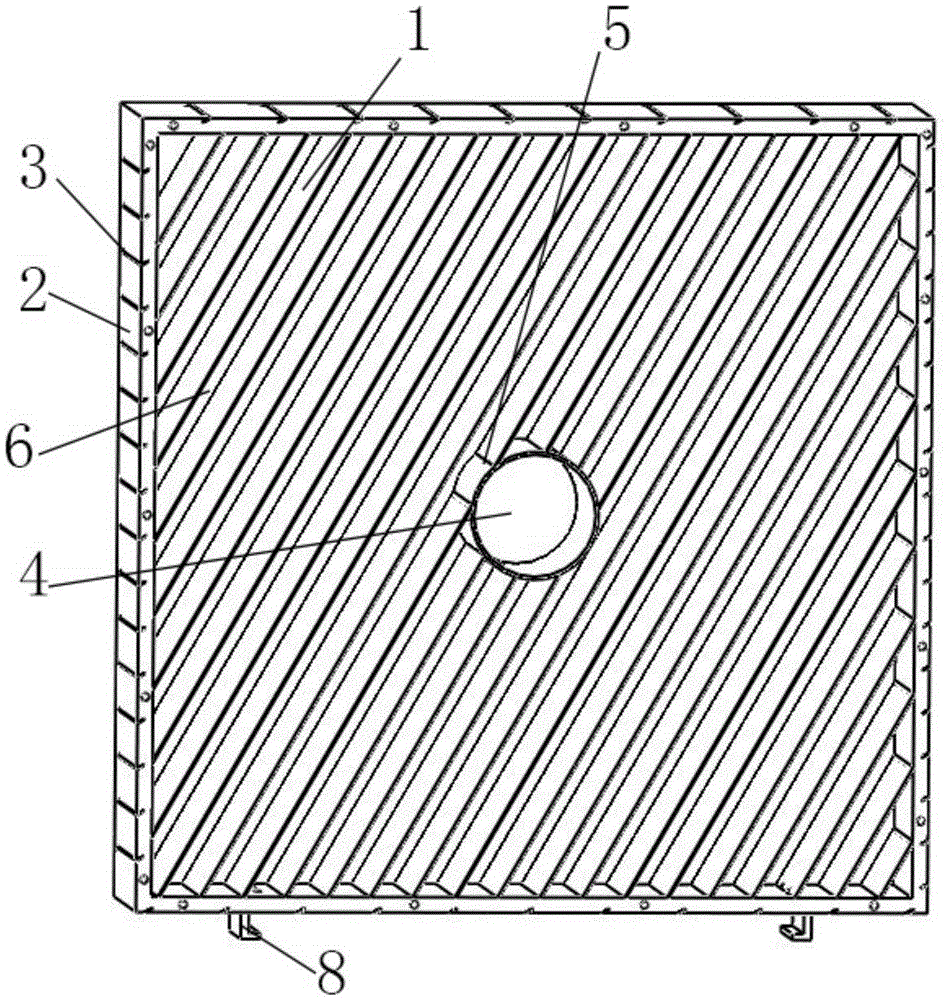

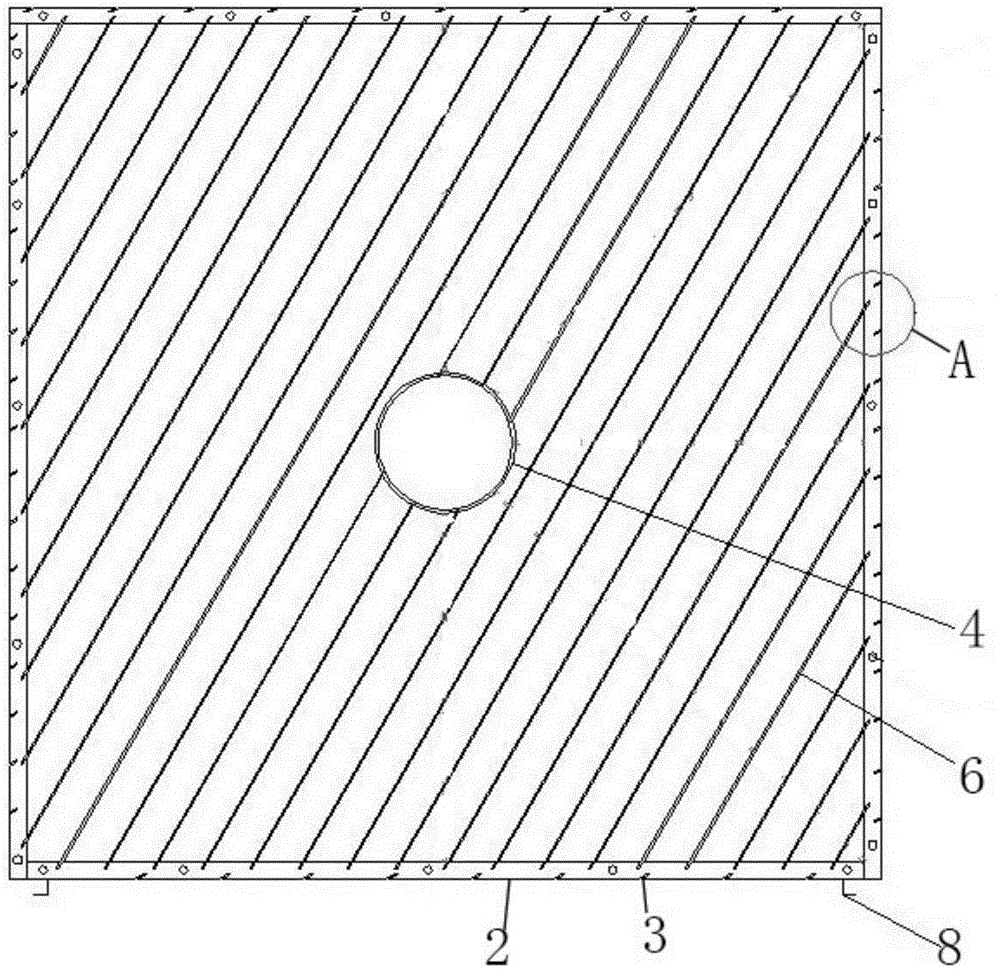

[0041] (1) Model assembly: first determine the orientation of the baffle groove according to the inclination angle of the required rock formation, then place the bottom plate of the model flat on the level ground, and connect the four baffles to the bottom plate through bolts in turn according to the determined orientation; Determine the length of the required baffles according to the spacing of the required rock formations, select the corresponding length of the baffles, and form different rock layer pouring zones through the insertion of the ends of the baffles and the grooves of the baffles; especially note that when the baffles When it is necessary to pass through the central cylinder, one end of the partition is required to be inserted into the groove on the surface of the cylinder to form an excavation tunnel;

[0042] (2) Pouring of composite rock formations: The pouring of composite rock formations is completed in sequence according to the layout of the pouring belt. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com