Plastic material quality prediction method

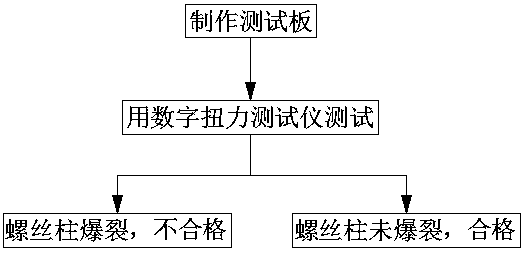

A quality and plastic technology, applied in the field of plastic material quality prediction, can solve the problems of screw column extrusion and bursting, rework of all processes, etc., to reduce the rework rate and reduce defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

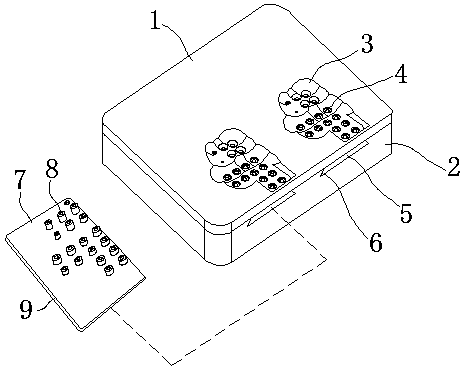

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

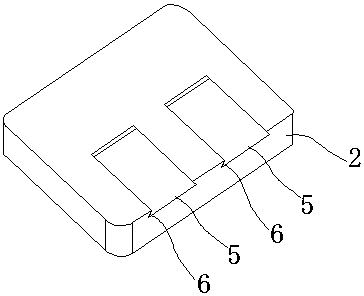

[0022] See figure 1 —— image 3 , the plastic lock screw strength tester of the present invention, comprises: base 2, cover plate 1, has the test groove 5 that is used to place test plate on the base 2, and there can be a plurality of test grooves 5, how many are provided on the cover plate 1 A test hole 4, the test hole 4 corresponds to the screw column 8 of the test board 7.

[0023] Specifically, a concave surface 3 is formed between the test hole 4 and the surface of the cover plate 1. The design of this concave surface 3 can increase the strength of the test hole 4, so that the test hole 4 can function as a keyboard when it is assembled with the keyboard. The strength effect of the shell.

[0024] More specifically, one end of the test slot 5 extends to the side of the base 2 .

[0025] Further, the side surface of the test groove 5 is an inner inclined surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com