Disc-wheel rotary-table zinc-alloy-impacting-hammer bearing-clamping-plate glass testing device

A test equipment, zinc alloy technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of glass fragments splashing, tape breaking, waste and pollution, etc., to avoid splash damage , convenient separation, and unified crushing test specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

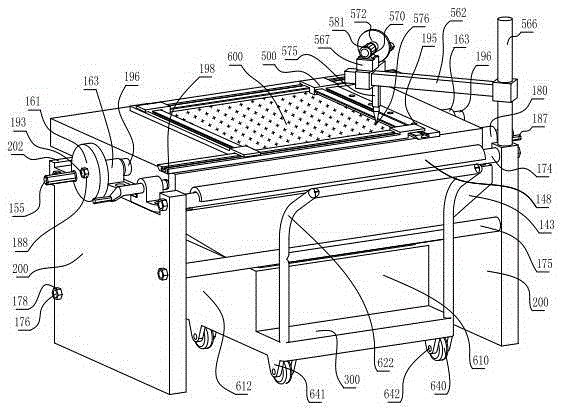

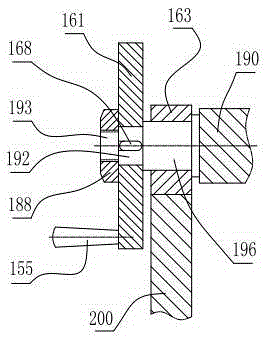

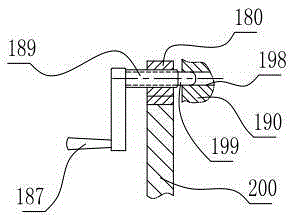

[0064] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 14 , Figure 15 , Figure 16 and Figure 17 Among them, the disc wheel turntable zinc alloy impact hammer bearing splint glass test equipment includes a test table 190 and a plate frame 200. There are four structural sleeves between the two plate racks 200. Each structural sleeve has a rod at both ends. Cooperate with pull rod nuts 178; the two sides of the test table 190 have a table rotating shaft 196, and the table rotating shafts 196 on both sides are respectively rotatably fixed in the table support 163, and the table support 163 is fixed on the plate frame 200 on the upper plane; the upper part of the panel frame 200 has a support block 202, and the support block 202 supports the lower plane of the test bench 190, and the four structural sleeve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com