Pulling-inserting lock pin plate wheel aluminum-based circular rail pressing plate glass detection machine

A technology of glass detection and pressing, which is applied in the direction of instruments, measuring devices, scientific instruments, etc. It can solve the problems of uneven force around the surrounding, long time spent, and splashing of glass fragments, so as to save the cost of test consumables, improve work efficiency, Avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

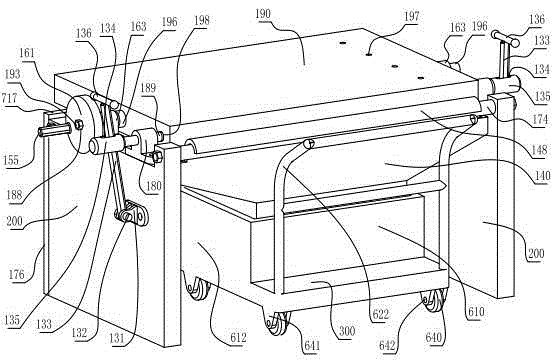

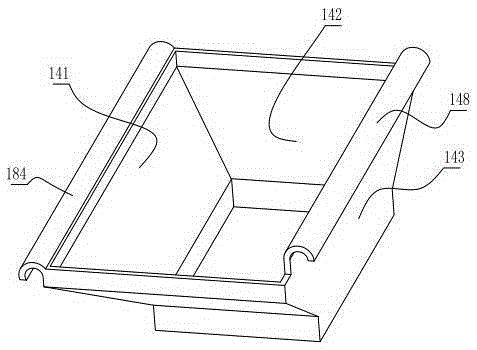

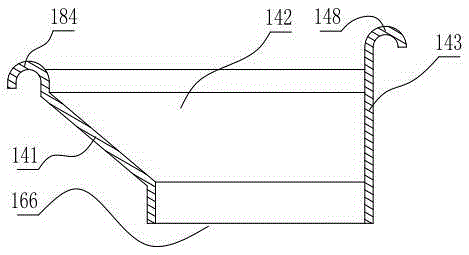

[0047] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 14 , Figure 15 , Figure 16 and Figure 17 :

[0048] Pulling and inserting lock pin plate wheel aluminum base turntable round track platen glass inspection machine, the overall frame consists of supporting side plates 200 on both sides, rear shear plate 176 and bottom narrow plate 175,

[0049] The upper planes of the supporting side plates 200 on both sides are respectively fixed with a platform support 163 and a lock pin support 180; Two lock pin seat screw holes 186, the side of the support side plate 200 is provided with the front upper through hole 274 of the frame and the upper through hole 279 of the frame, and the outer side of the support side plate 200 has an operation seat screw hole 232 ;

[0050] The test plate 190 has a pressing pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com