Lens-free particle microscopic localization device and method based on LED light sources

A technology of LED light source and positioning device, which is used in measurement devices, particle size analysis, particle and sedimentation analysis, etc., can solve problems such as low time efficiency, particles with different axial positions easily influence each other, speckle noise limiting imaging positioning accuracy, etc. , to achieve the effect of improving recovery accuracy, simple device structure, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

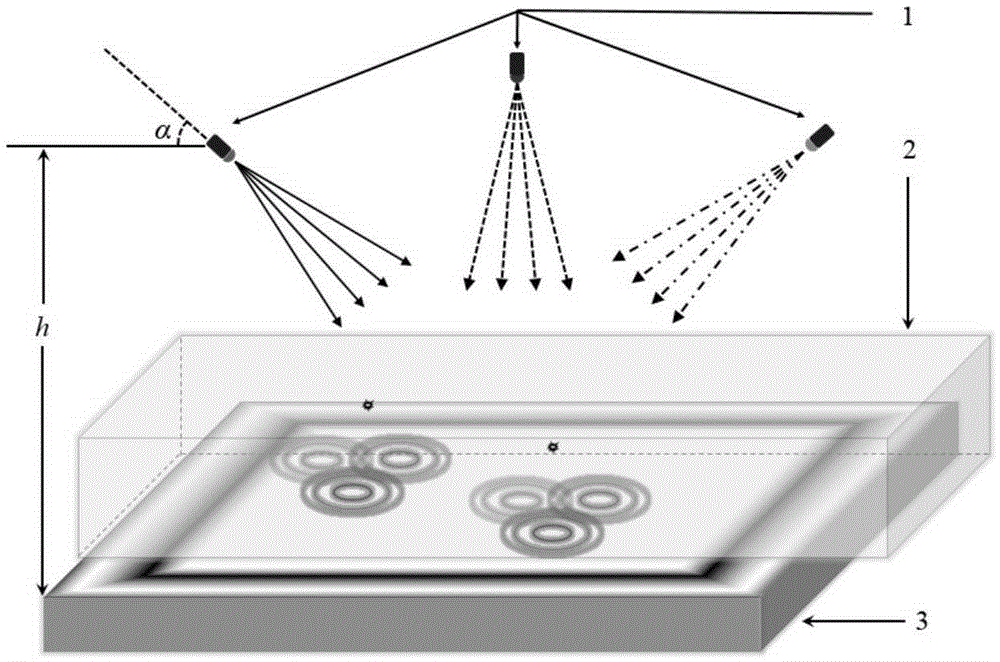

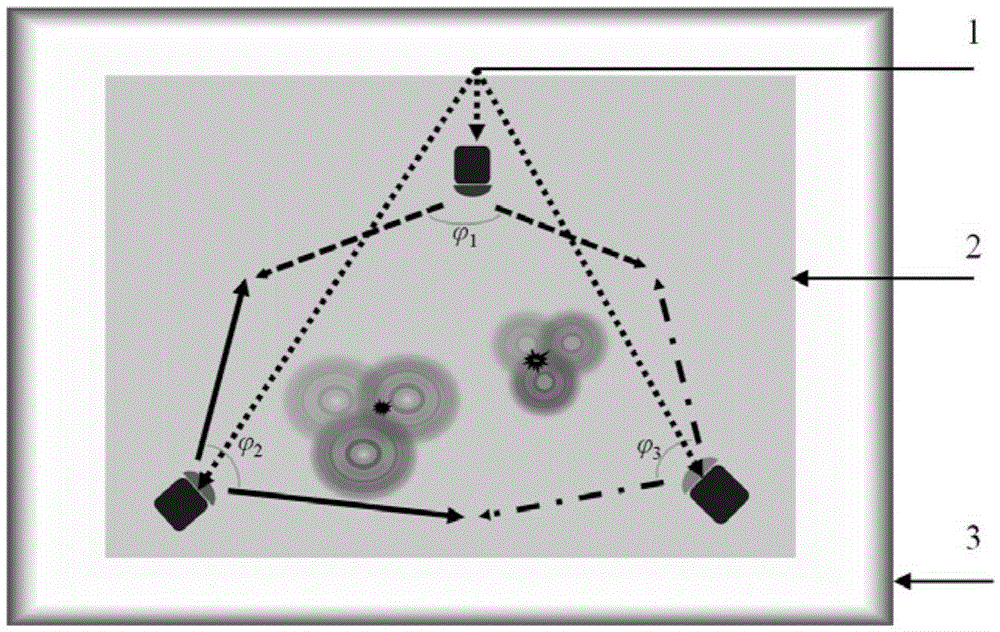

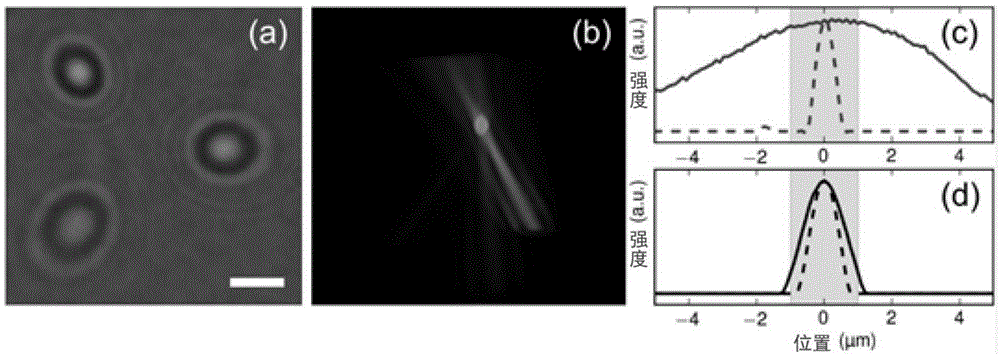

[0010] Such as figure 1 and figure 2 As shown, the lensless particle micropositioning device based on the three-color LED light source of the present invention includes an LED light source 1, a sample placement groove 2, a CMOS or CCD camera sensor 3, and more than two LED light sources 1 are arranged in the sample placement groove 2 different positions on the top to irradiate the sample at different angles; the sample placement groove 2 is set above the camera sensor 3, and the distance between the lower surface of the sample placement groove 2 and the camera sensor 3 is as small as possible, and both Keep parallel to preserve interferometric image quality.

[0011] The LED light source 1 of the lensless particle micropositioning device based on the LED light source of the present invention uses the same color or different colors. When using the same color LED, the camera sensor 3 is monochrome, and when using different color LEDs, the camera sensor 3 is color. The distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com