Automatic positioning belt laser height measurement PCB dispensing method

An automatic positioning and PCB board technology, applied in image data processing, instruments, calculations, etc., to achieve the effect of easy implementation, convenient operation, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the drawings and specific embodiments, however, the embodiments of the present invention are not limited thereto.

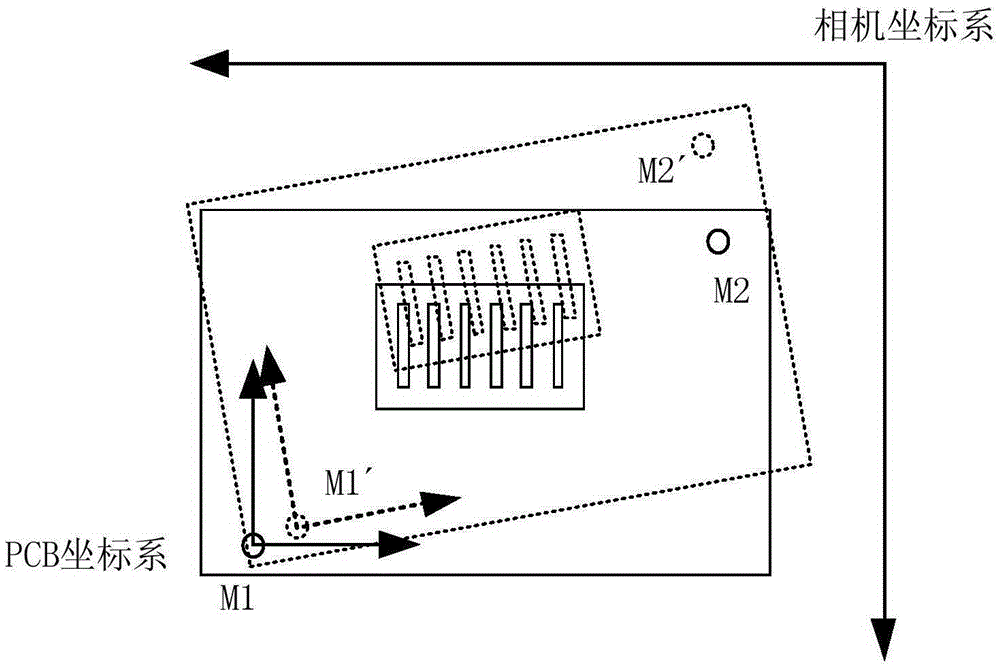

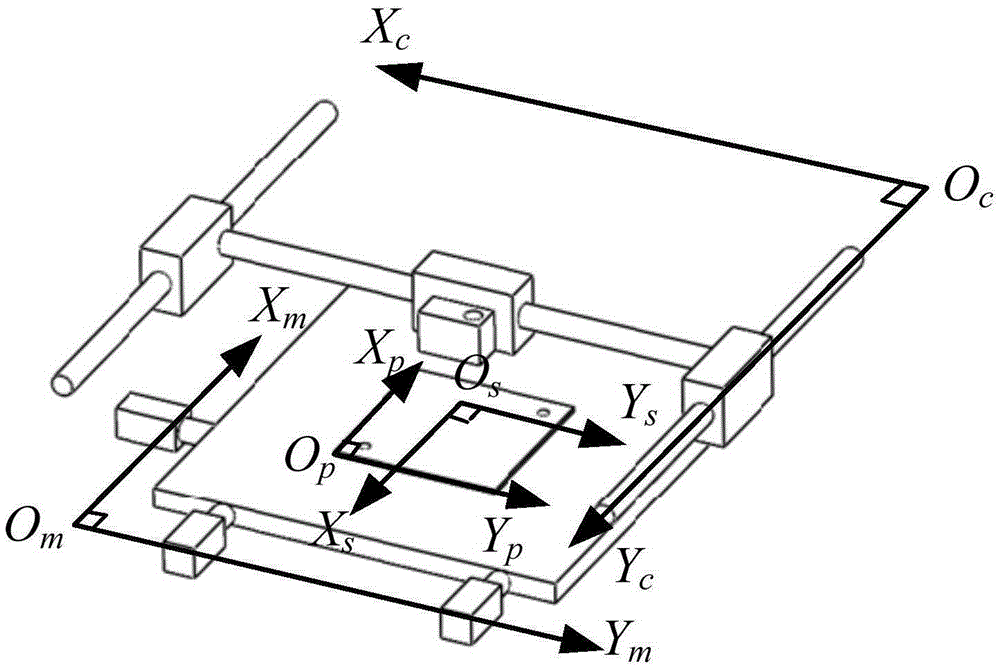

[0027] Such as figure 1 and figure 2 As shown, a method of dispensing PCB with laser height measurement for automatic positioning, including the following steps:

[0028] A) Keep the camera coordinate system in a fixed state during the operation of the printing press, and use the camera coordinate system as a reference to mark the dispensing position information of the PCB board;

[0029] B) Set M1 and M2 as the marking points of the PCB dispensing area recorded during dispensing learning, and M1' and M2' are the marking points of another PCB board after re-entering the board;

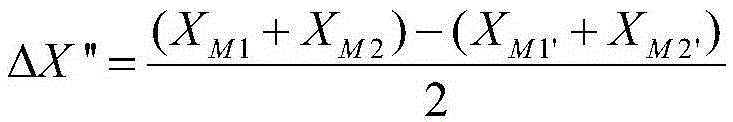

[0030] C) The dispensing area is rotated and translated due to the deviation of the stop plate position of the PCB, and the line segment is defined and The included angle is ω, and the translat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com