Hydraulic seal electrical connector

An electrical connector, hydraulic sealing technology, applied in the connection, the parts of the connecting device, the circuit, etc., can solve the problems of sealing failure, easy cracking of the glass, etc., to improve the sealing performance, small cross-sectional area, and improve working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

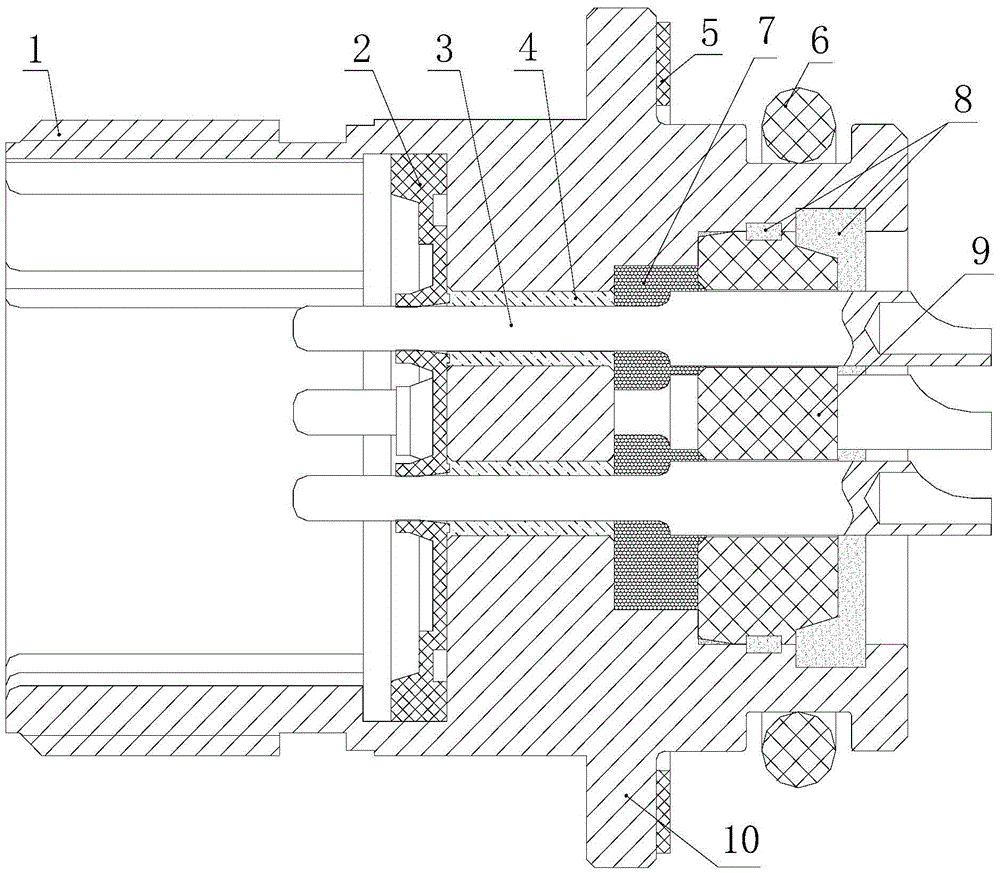

[0022] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0023] like figure 1 As shown, a hydraulically sealed electrical connector according to the present invention includes a housing 1, an interface gasket 2 and pins 3. Inside the housing 1 is a sintered single-core glass insulator 4, and the pins 3 are fixed on In the middle of the single-core glass insulator 4, and the two ends of the pins 3 respectively extend to both sides of the single-core glass insulator 4, the interface gasket 2 is installed on the left side of the single-core glass insulator 4, and the right side of the single-core glass insulator 4 Filled with sealant 7. The casing 1 of the present invention uses a sintered single-core glass insulator 4, which has a small cross-sectional area and can withstand high liquid pressure without breaking. In the shell 1, the interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com