Fuel injection valve

A fuel injection valve and valve core technology, which is applied to fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as prolonged time, and achieve the effects of preventing sticking, fast response, and small deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

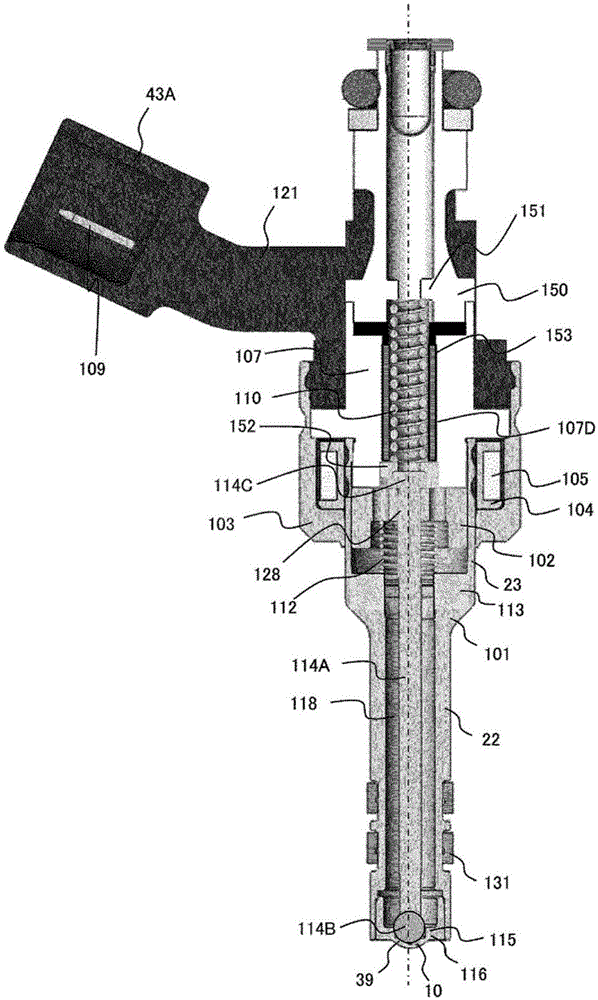

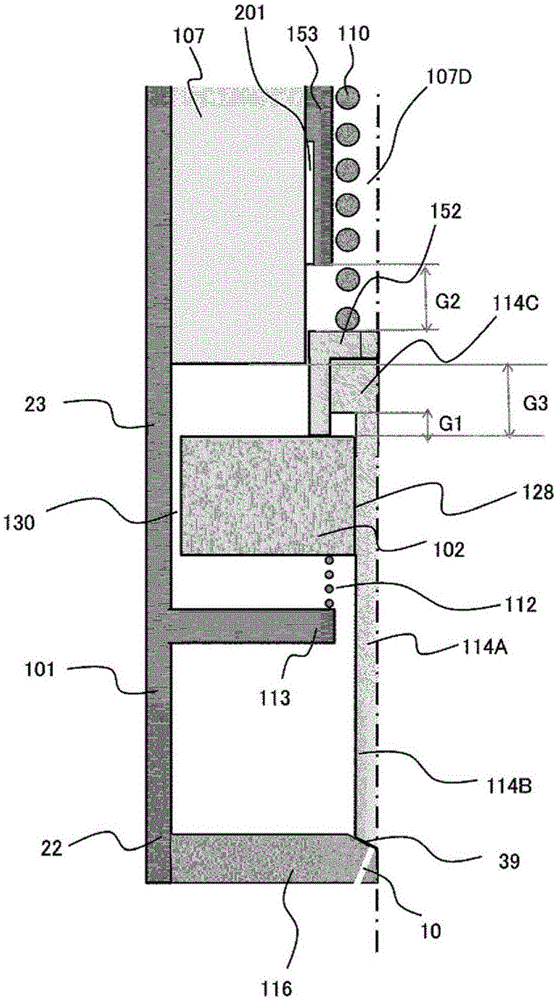

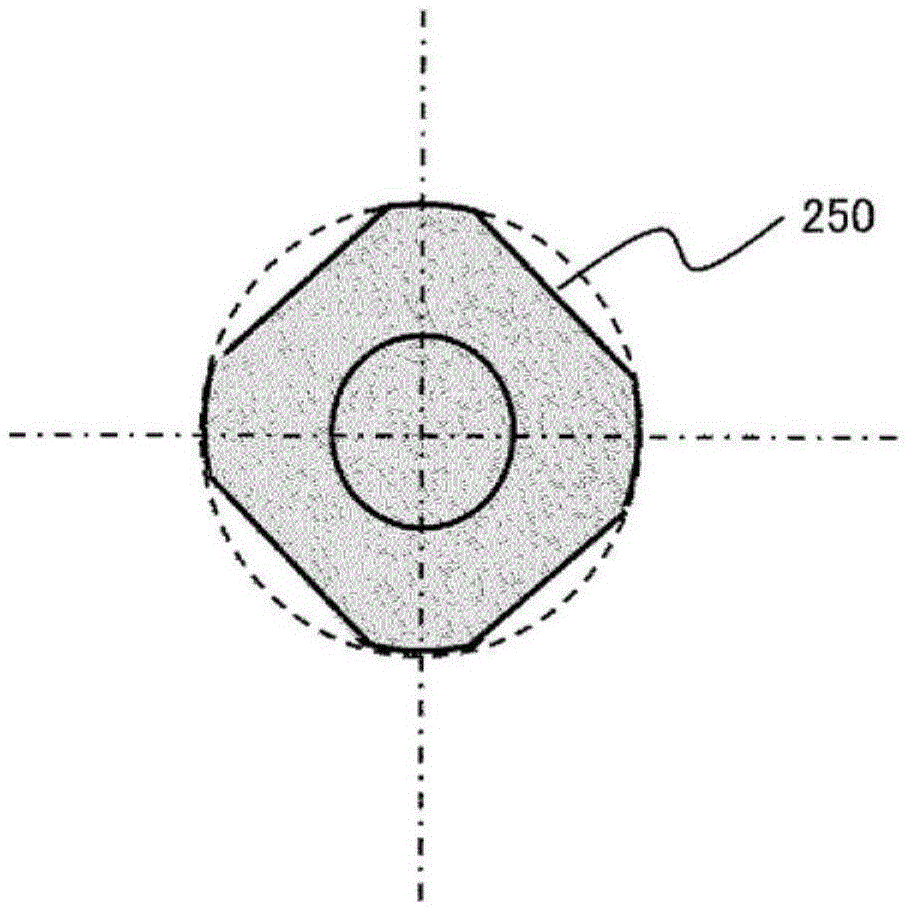

[0038] Use the following Figure 1-7 The figure illustrates the construction of an embodiment of the fuel injection valve of the present invention. figure 1 It is a longitudinal sectional view of the fuel injection valve of this embodiment. Figures 2, 4, and 6 are figure 1A partially enlarged view of , showing the details of the fuel injection valve in this embodiment. In this figure, the dimensions of parts and gaps are exaggerated compared to the actual scale to make the structure easier to understand, and unnecessary parts are omitted to explain the functions.

[0039] The nozzle holder 101 includes a small-diameter cylindrical portion 22 with a small diameter and a large-diameter cylindrical portion 23 with a large diameter. The fixed core 107 is press-fitted into the inner peripheral portion of the large-diameter cylindrical portion 23 of the nozzle holder 101, and welded at the press-fit contact position. This welded joint seals the gap formed between the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com