Flow pipeline for fire engine

A flow pipe and fire truck technology, applied in fire rescue and other directions, can solve the problems of intermittent, discontinuous foam, affecting the fire extinguishing effect, etc., and achieve good foaming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

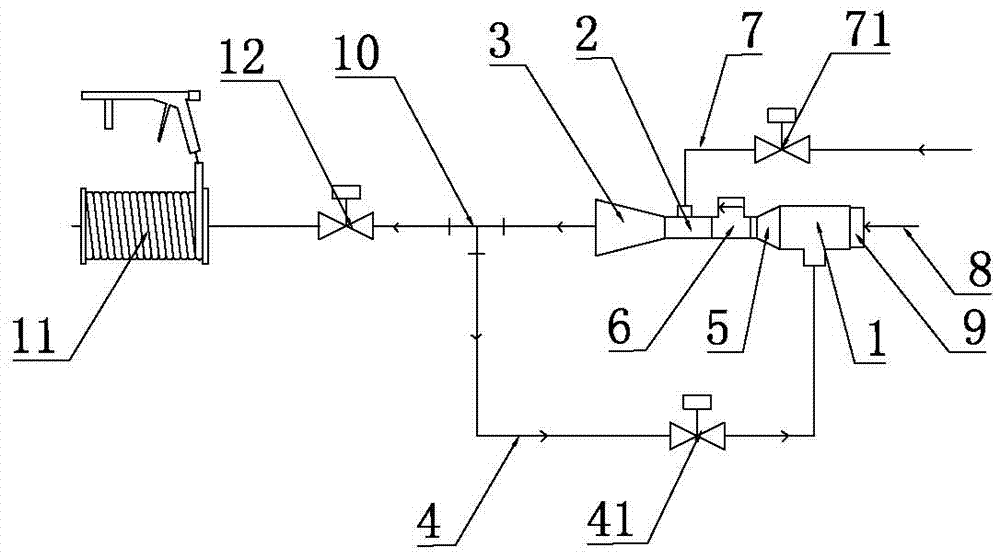

[0044] One of the specific implementations of a flow pipeline for a fire truck of the present invention, such as figure 1 As shown (the direction of the arrow in the figure is the flow direction of the liquid flow in the pipeline), its structure includes a suction pipe 1, a throat pipe 2 and a diffuser pipe 3 connected in sequence according to the flow direction of the liquid flow. The first water inlet of the suction pipe 1 passes through the high pressure The water pipe 8 is connected to the water pump, the second water inlet of the suction pipe 1 is connected to the water outlet of the diffuser pipe 3 through the return pipe 4, the return pipe 4 is provided with a return control valve 41, and a horn-shaped The throat inlet pipe 5, the large port of the throat inlet pipe 5 is connected to the suction pipe 1, the small port of the throat inlet pipe 5 is connected to the throat pipe 2, and the end of the throat pipe 2 near the diffuser pipe 3 is connected with a foam pipe 7, an...

Embodiment 2

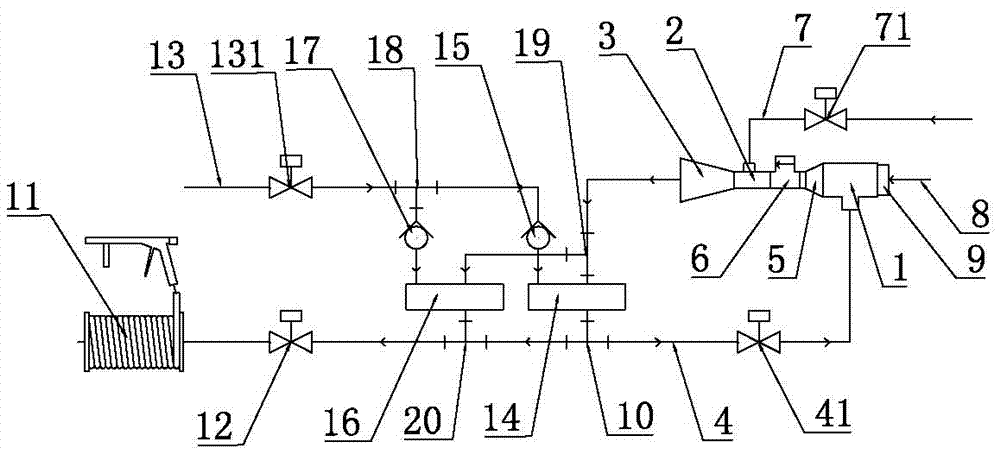

[0051] The second specific embodiment of a flow pipeline for a fire truck of the present invention is as follows: figure 2As shown (the direction of the arrow in the figure is the flow direction of the liquid flow in the pipeline), the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, here No further details will be given. The difference between this embodiment and Embodiment 1 is that an air pipe 13 for conveying compressed air is also connected to the water outlet of the diffuser pipe 3, and a first proportional control valve 14 is provided at the connection between the air pipe 13 and the diffuser pipe 3, and then The flow value of the foam mixture and the flow value of the compressed air can be regulated continuously and in a certain proportion. The air pipe 13 is also provided with a first one-way valve 15 to prevent the compressed air from flowing backward. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com