A protective nozzle mechanism

A gripper sheath and indenter technology, which is applied in the direction of manipulator, metal processing, metal processing equipment, etc., can solve the problem of easy damage of the suction nozzle, and achieve the effect of preventing the impact from falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

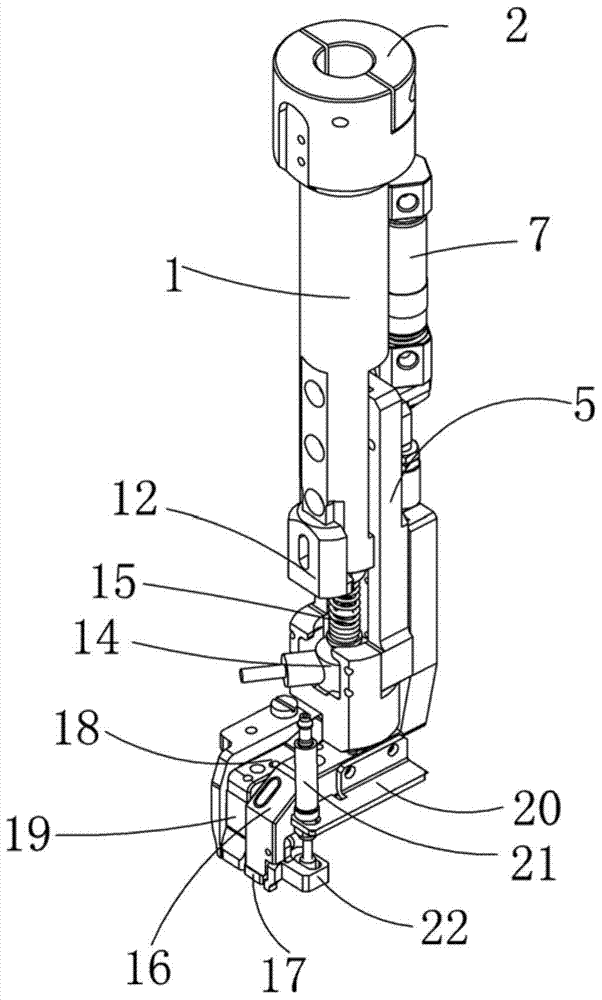

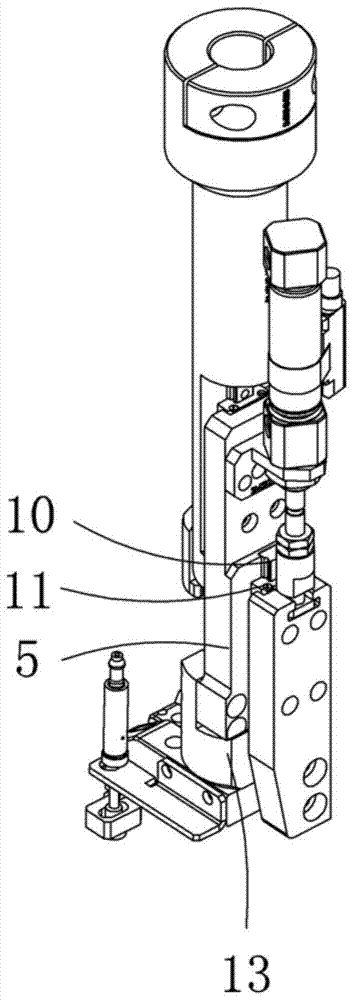

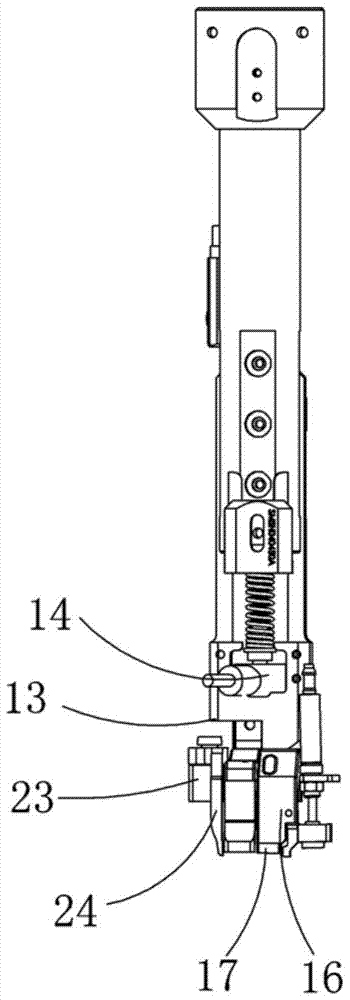

[0019] Examples, see attached Figure 1~4 , a suction nozzle mechanism with protection, including an R-axis extension shaft 1, a clamping block 2 is installed on the upper part of the R-axis extension shaft, the R-axis extension shaft and the manipulator can be locked and fixed by the clamping block, and the manipulator operates Drive the present invention to absorb parts and assemble the parts on the product, and then carry out pressure maintenance through the pressure head.

[0020] An R-axis slide rail 3 is installed on the right side of the R-axis extension shaft, an R-axis slider 4 is installed on the R-axis slide rail, and a connecting block 5 is installed on the R-axis slider. The upper part of the connecting block passes through the suction nozzle The cylinder fixing frame 6 is equipped with a suction nozzle cylinder 7; the piston rod lower end of the suction nozzle cylinder is connected to the pressure head connecting block 9 through a floating joint 8; the pressure h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com